Large-section groove-shaped channel straddle type drill carriage

A straddle-type, large-section technology, used in tunnels, directional drilling, earth-moving drilling, etc., can solve the problems of discontinuous material transportation, complex working face procedures, and high labor intensity of workers, and achieve high anchorage operation efficiency, The effect of large weight and large torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

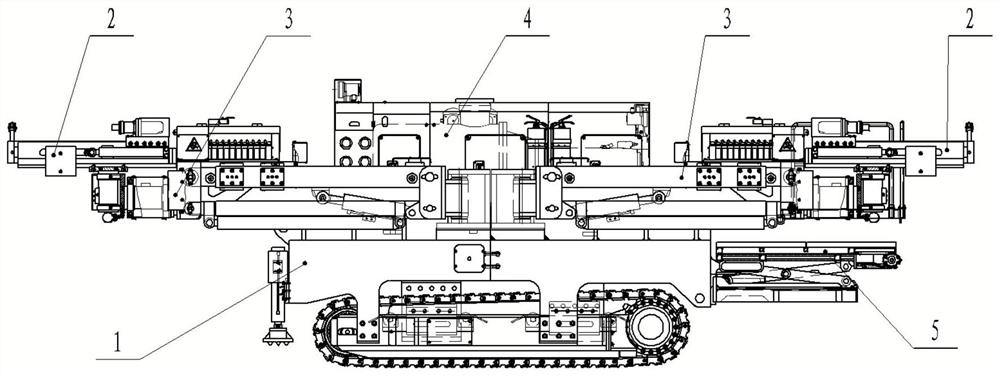

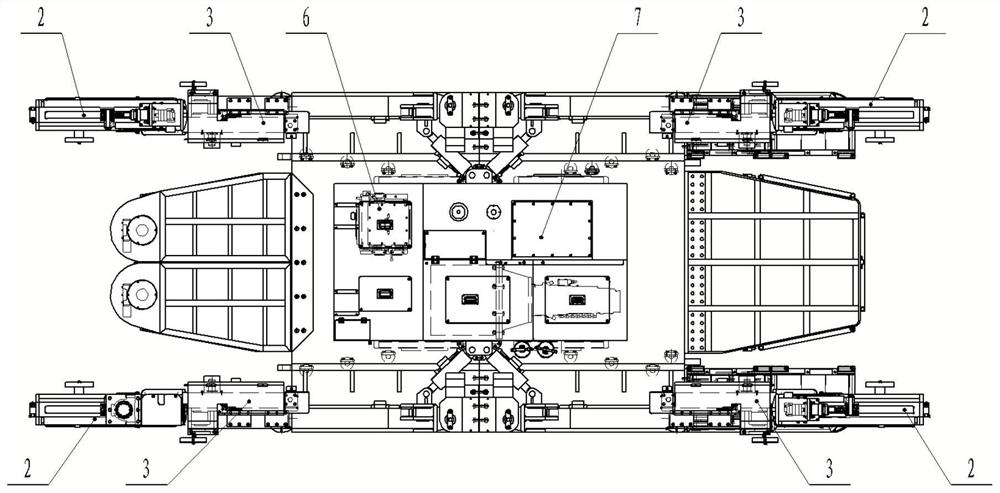

[0034] like Figure 1 to Figure 2As shown, a large cross-section channel straddle drilling rig described in this embodiment includes: a body part 1, four airborne rock bolt rigs 2, four drill arms 3, a guard part 4, and two groups Lifting work platform 5, electrical system 6 and hydraulic system 7; the body part 1 is arranged under the guard plate part 4 to provide support for the whole unit, and the four airborne rock bolters 2 are respectively arranged on the four booms 3, the four drill arms are symmetrically arranged in four regions above the body part 1, and the guard plate part 4 is installed at the middle position above the body part 1. There are two elevating work platforms 5 in total. , symmetrically arranged on the rear end surface of the body part 1, the electrical system 6 is installed at the right front side of the body part 1, and the hydraulic system 7 is installed at the right rear side of the body part 1.

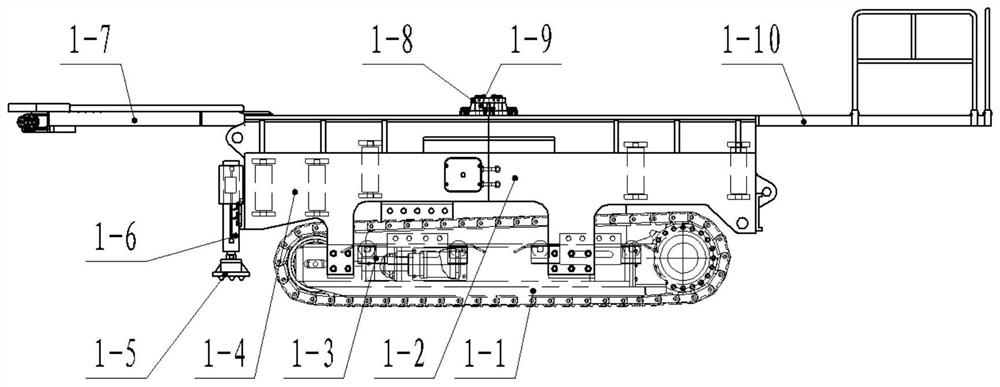

[0035] like Figure 3 to Figure 5 As shown, the bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com