Garlic pretreatment substance, garlic extract, seasoning, and preparation methods and application of garlic pretreatment substance, garlic extract and seasoning

A garlic extract and pretreatment technology, applied to the application of garlic extract in food, a method and the obtained garlic extract, a method and the obtained condiment, and the field of garlic pretreatment, which can solve the problem that cannot be solved Give condiments garlic flavor and taste, unsuitable condiments, weak product flavor, etc., to achieve the effect of retaining garlic flavor and taste, harmonious fragrance, and rich aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

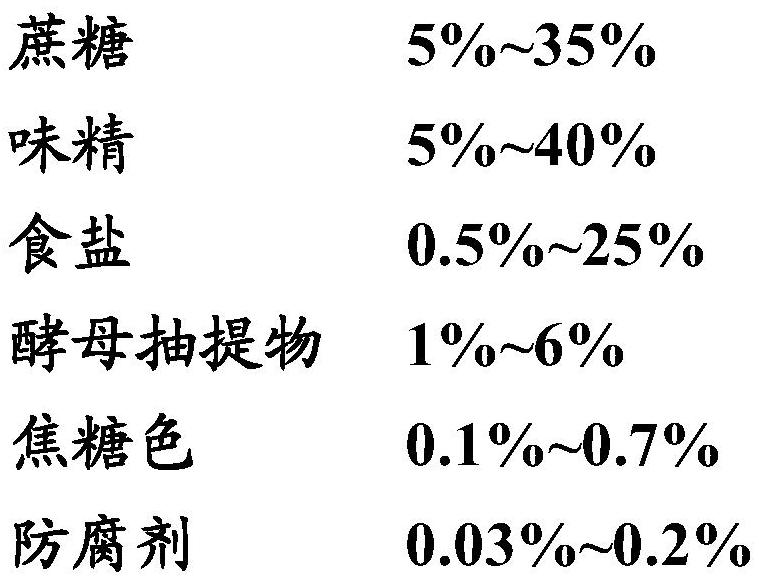

Method used

Image

Examples

Embodiment 1

[0075] (1) Remove the stems of fresh garlic without peeling, wash and air-dry, add 10% w / w ethanol aqueous solution according to the weight ratio of 1:3, soak at 0-4°C for 24 hours, and put the whole soaking system at -10°C Freeze for 3 hours; then heat and evaporate the ethanol solution at 60°C, chop and mix into 3-5mm garlic grains A by a chopping machine;

[0076] (2) According to the weight ratio of 1:8, add 70% w / w ethanol aqueous solution to garlic A, mix evenly, pour into the extraction tank, pressurize to 0.2MPa to extract for 20min, then pressurize to 0.4MPa to extract for 30min, Continue to pressurize to 0.6MPa and extract for 15 minutes, press filter to obtain garlic extract A;

[0077] (3) Destem and peel the fresh garlic, chop it into pieces, marinate it with salt-sucrose solution (containing 5% w / w of salt and 15% w / w of sucrose) at 60°C for 5 days, and then grind it through a colloid mill into Garlic paste A;

[0078] (4) Mix garlic extract A and garlic paste ...

Embodiment 2

[0081] (1) Remove the stems of fresh garlic without peeling, wash and air-dry, add 20% w / w ethanol aqueous solution according to the weight ratio of 1:2, soak at 0-4°C for 21 hours, and put the whole soaking system at -15°C Freeze for 2 hours; then heat and evaporate the ethanol solution at 80°C, chop and mix into 3-5mm garlic grains B with a chopping machine;

[0082] (2) According to the weight ratio of 3:8, add 80% w / w ethanol aqueous solution to garlic B, mix evenly, pour into the extraction tank, pressurize to 0.15MPa to extract for 30min, pressurize to 0.35MPa to extract for 40min, increase Press to 0.55MPa and extract for 23 minutes, press filter to obtain garlic extract B;

[0083] (3) Destem and peel the fresh garlic, chop it into pieces, marinate it with a salt-sucrose solution (containing 10% w / w of salt and 20% w / w of sucrose) at 50°C for 10 days, and then grind it through a colloid mill to form Garlic B;

[0084] (4) Mix garlic extract B and garlic paste B evenl...

Embodiment 3

[0087] (1) Remove the stems of fresh garlic without peeling, wash, air-dry, add 30% w / w ethanol water solution according to the weight ratio of 1:6, soak at 0-4°C for 18 hours, and then freeze at -10°C for 1 hour; Afterwards, heat and evaporate the ethanol solution at 70°C, chop and mix into 3-5mm garlic grains C by a chopping machine;

[0088] (2) Add 95% w / w ethanol aqueous solution to Garlic C at a weight ratio of 5:8, mix well and pour into an extraction tank, pressurize to 0.1MPa for extraction for 40min, then pressurize to 0.3MPa for extraction for 50min, Continue to pressurize to 0.5MPa and extract for 30 minutes, press filter to obtain garlic extract C;

[0089] (3) Destem and peel the fresh garlic, chop it into pieces, marinate it with salt-sucrose solution (containing 5% w / w of salt and 8% w / w of sucrose) at 40°C for 15 days, and then grind it into Garlic paste C;

[0090] (4) Mix garlic extract C and garlic paste C evenly in a weight ratio of 1:1, grind them, pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com