Steel structure manufacturing and machining tool for house splicing and using method of thereof

A technology for processing tools and steel structures, which is applied to steel structure manufacturing and processing tools for house splicing and its application field, can solve the problems of wasting labor, easily scratching workers' fingers, etc., and achieves the effect of preventing displacement and accelerating production speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

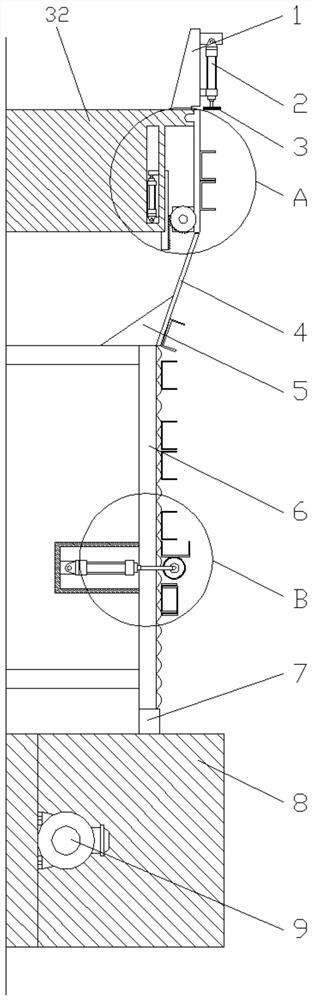

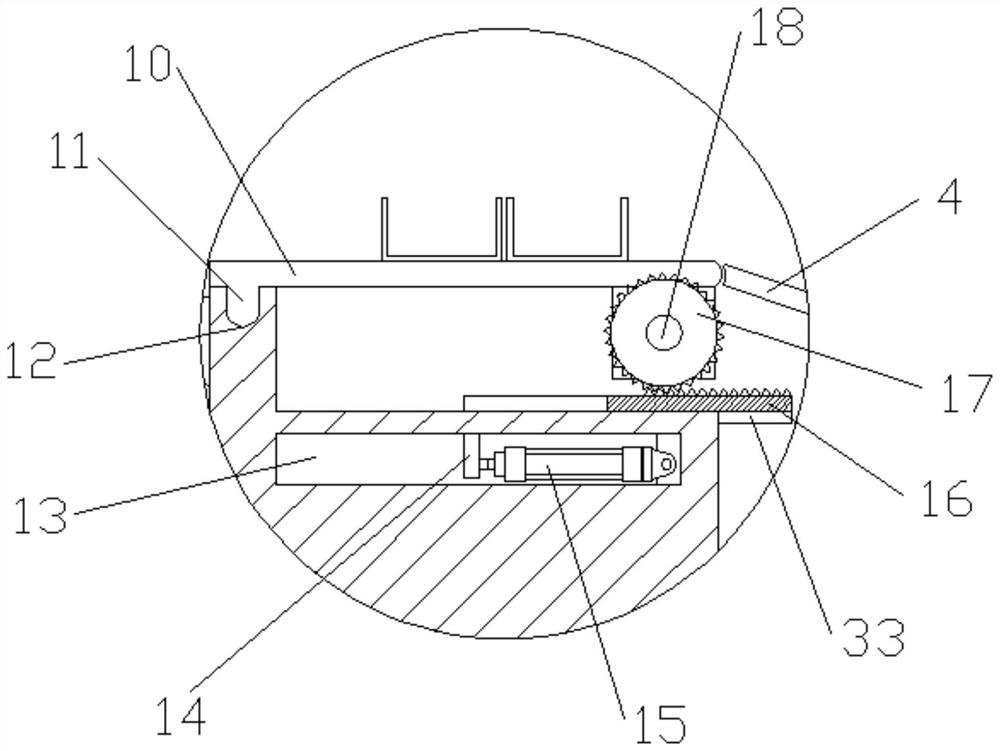

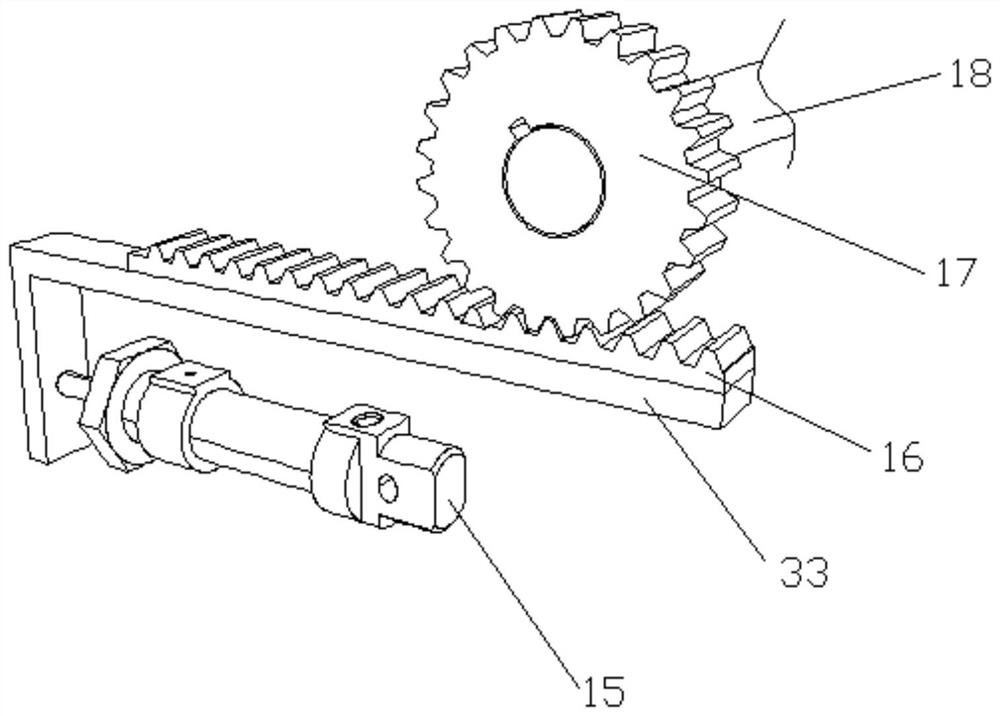

[0042] see Figure 1-4 , according to an embodiment of the present invention, a steel structure manufacturing and processing tool for house splicing includes a pushing mechanism, a transmission buckle mechanism, a stacking mechanism and a monolithic mechanism, and the pushing mechanism includes a fixed platform 32, and the top end of the fixed platform 32 There is a flap 10, the first cylinder 2 is arranged on one side of the flap 10, the output end of the first cylinder 2 is fixed with a first push plate 3, and the flap 10 is far away from the bottom of one end of the first cylinder 2 Gears 17 are fixed, and connecting rods 18 are fixed between the gears 17. The body of the connecting rods 18 is provided with a first bearing, and the first bearing is fixed on the fixed table 32. The bottom of the gears 17 is provided with There is a slider 33, the top of the slider 33 is fixed with a rack 16, the rack 16 is meshed with the gear 17, and the fixed table 32 is provided with a li...

Embodiment 2

[0045] see figure 1 , Figure 5 , Figure 6 and Figure 7 , for the palletizing mechanism, the palletizing mechanism includes an engaging plate 7, the engaging plate 7 is placed on the end of the roller conveyor belt 6 away from the fixed table 32, and the connecting plate 7 and the roller conveyor belt 6 share The end of the connecting plate 7 away from the roller conveyor belt 6 is provided with a back plate 25, the bottom of the connecting plate 7 is connected with an electric push rod 28, and the output end of the electric push rod 28 is fixed on the bottom of the connecting plate 7 .

[0046] Through the above scheme of the present invention, the palletizing mechanism of the present invention uses the transmission of the roller conveyor belt 6 to transfer the light steel keels of the buckle to the connecting plate 7, and uses the roller conveyor belt 6 to transmit the light steel keels of the buckle, and squeeze each other to the backboard 25 side, until the back plat...

Embodiment 3

[0048] see figure 1 , Figure 5 , Figure 6 and Figure 7 , for the monolithic mechanism, the monolithic mechanism includes a fixed base 26, the top of the fixed base 26 is provided with a second rotating shaft 30, and the shaft body on both sides of the second rotating shaft 30 is provided with threads 24, and the second The middle end of the rotating shaft 30 is provided with a third bearing 29, and the third bearing 29 is fixed on the fixed base 26. The two sides of the second rotating shaft 30 are provided with monolithic plates 23, and the monolithic plates 23 and The second rotating shaft 30 is connected by the thread 24, the two ends of the second rotating shaft 30 are provided with a fixed plate 8, and a limit rod 27 is arranged between the fixed plates 8, and the two limit rods 27 The end is fixed on the fixed plate 8, the inside of the whole material plate 23 has a limit hole, the limit rod 27 runs through the limit hole, the electric push rod 28 and the fixed pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com