Extraction method of epichlorohydrin-containing water phase

An epichlorohydrin and extraction technology, which is applied in the field of extraction of an aqueous phase containing epichlorohydrin, can solve problems such as entrainment, and achieve the effects of high methanol quality and high extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

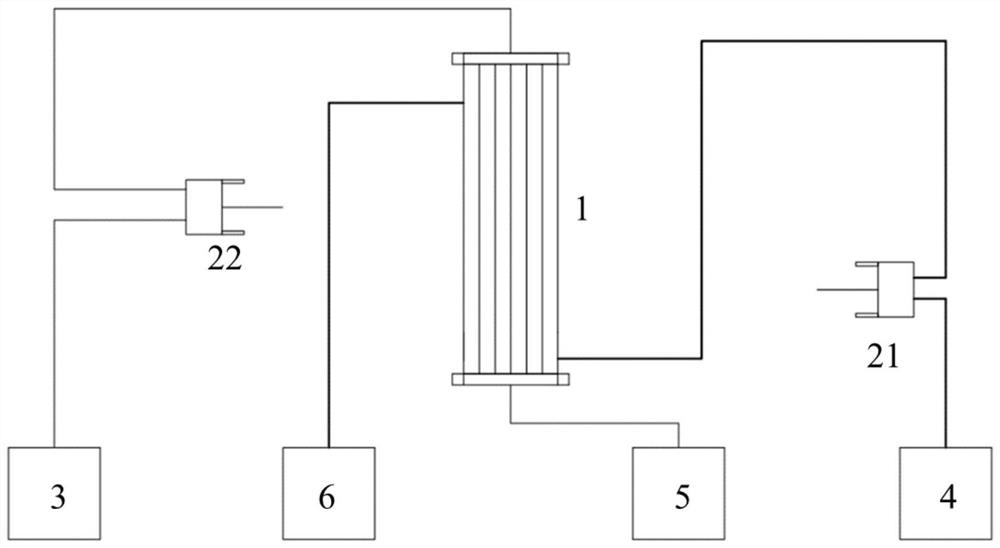

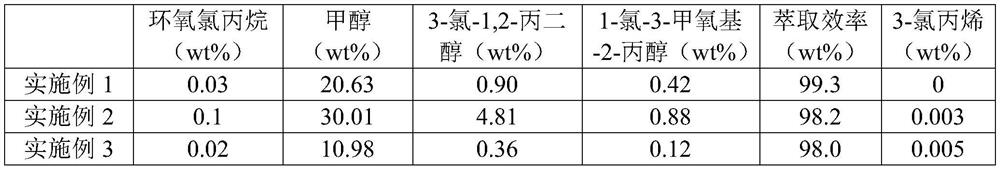

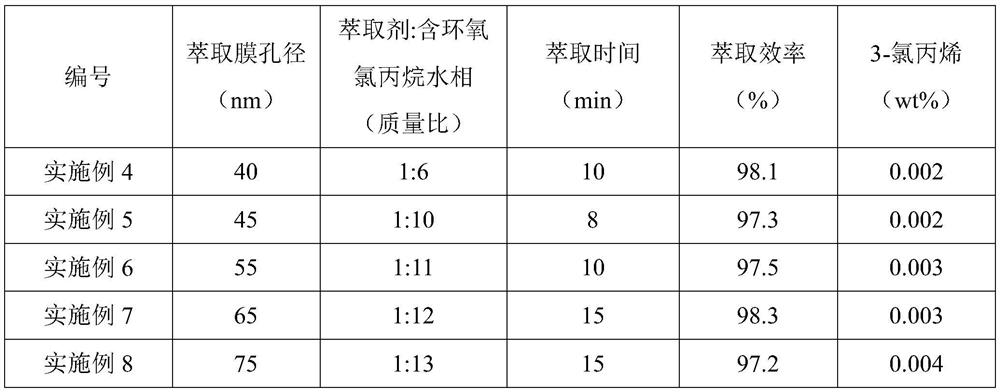

[0051] This embodiment provides a method for extracting an aqueous phase containing epichlorohydrin, which is carried out using the above-mentioned device, and specifically includes the following steps:

[0052] Use a flow pump to send 3-chloropropene as an extraction agent into the inner side of the membrane in the hollow fiber membrane extractor, and stop the pump after filling the membrane tube. The membrane is a polytetrafluoroethylene membrane with an average pore size of 60 nm. After 30 minutes of infiltration, Then the water phase containing epichlorohydrin is sent to the shell side of the hollow fiber membrane extractor by flow pump, that is, the outer side of the membrane. The timing starts when the contact occurs and the extraction occurs, and the membrane extraction is carried out for 10 minutes. The raffinate water phase and the extracted oil phase are extracted from the shell side outlet and the tube side outlet of the membrane extractor respectively.

[0053] The...

Embodiment 2

[0055] This embodiment provides a method for extracting an aqueous phase containing epichlorohydrin, which is carried out using the above-mentioned device, and specifically includes the following steps:

[0056] Use a flow pump to send 3-chloropropene as an extraction agent into the inner side of the membrane tube in the hollow fiber membrane extractor, and stop the pump after filling the membrane tube. The membrane is a polytetrafluoroethylene membrane with an average pore size of 50 nm. After 60 min of infiltration, Then the water phase containing epichlorohydrin is sent to the shell side of the hollow fiber membrane extractor by flow pump, that is, the outer side of the membrane. The timing starts when the contact occurs and the extraction occurs, and the membrane extraction is carried out for 8 minutes. The raffinate water phase and the extracted oil phase are extracted from the shell side outlet and the tube side outlet of the membrane extractor respectively.

[0057] The...

Embodiment 3

[0059] This embodiment provides a method for extracting an aqueous phase containing epichlorohydrin, which is carried out using the above-mentioned device, and specifically includes the following steps:

[0060] Use a flow pump to send 3-chloropropene as an extraction agent into the inner side of the membrane tube of the hollow fiber membrane extractor, and stop the pump after filling the membrane tube. The membrane is a polytetrafluoroethylene membrane with an average pore diameter of 70 nm. After 20 minutes of infiltration, Then the water phase containing epichlorohydrin is sent to the shell side of the hollow fiber membrane extractor by flow pump, that is, the outer side of the membrane. The timing starts when the contact occurs and the extraction occurs, and the membrane extraction is carried out for 12 minutes. The raffinate water phase and the extracted oil phase are extracted from the shell side outlet and the tube side outlet of the membrane extractor respectively.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com