Optical adhesive

A technology of optical adhesives and sols, applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve problems such as poor refractive index, affecting quality, and excessive thickness of the adhesive film, and achieve improved anti-yellowing Variable effect, fast curing speed, and improved refractive index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

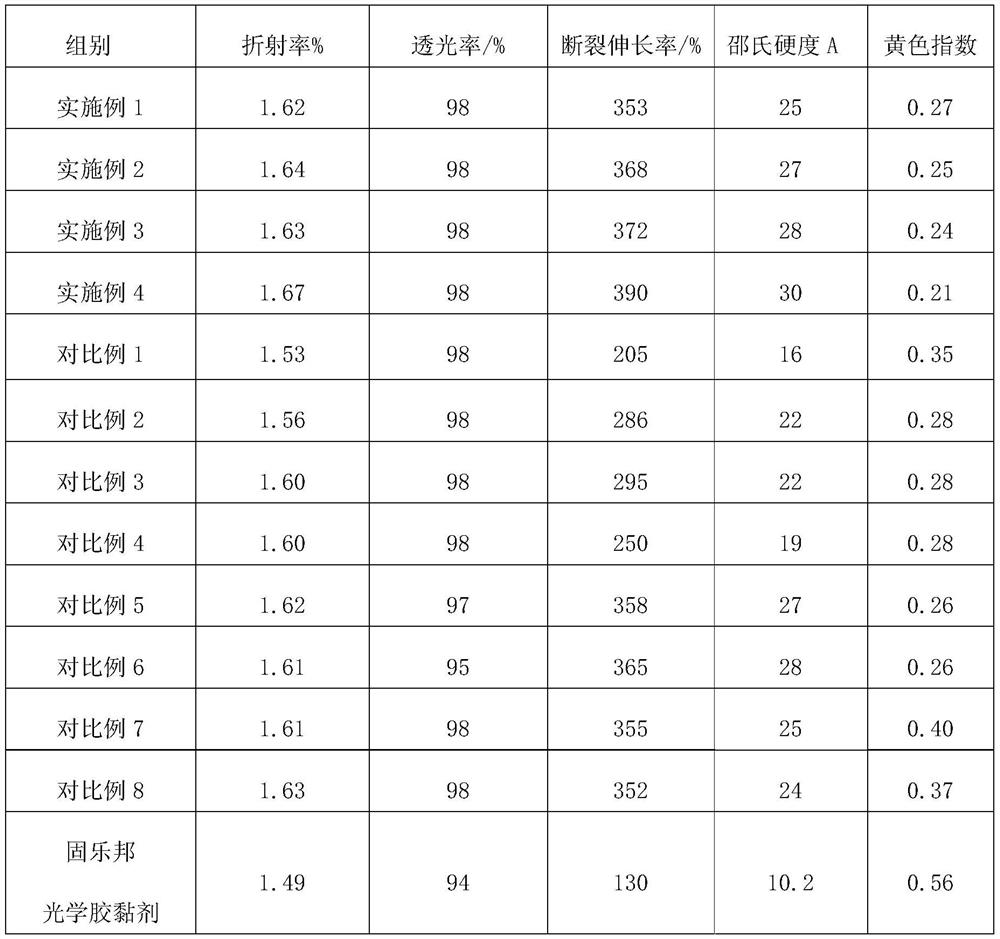

Examples

Embodiment 1

[0029] An optical adhesive comprising the following components in parts by weight: 30 parts of o-phenylphenoxyethyl acrylate, 20 parts of ethoxylated bisphenol A dimethacrylate, 10 parts of tetrahydrofurfuryl alcohol acrylate, 10 parts of trimethylol cyclohexyl acrylate, 8 parts of bisphenol fluorene acrylate, 3 parts of organic-inorganic hybrid acrylate, 0.5 parts of antioxidant, 2 parts of initiator, and 1 part of silicone additive.

[0030] The organic-inorganic hybrid acrylate nano-silica organic-inorganic hybrid acrylate, nano-titanium dioxide organic-inorganic hybrid acrylate and nano-zirconia organic-inorganic hybrid acrylate.

[0031] The preparation method of the nano-silica organic-inorganic hybrid acrylate or nano-zirconia organic-inorganic hybrid acrylate is: mixing acrylate resin, nano-silica sol / nano-titania sol / nano-zirconia sol , and stirred for 2 hours to obtain nano-silica organic-inorganic hybrid acrylate or nano-zirconia organic-inorganic hybrid acrylate. ...

Embodiment 2

[0035] An optical adhesive comprising the following components in parts by weight: 30 parts of o-phenylphenoxyethyl acrylate, 20 parts of ethoxylated bisphenol A dimethacrylate, 10 parts of tetrahydrofurfuryl alcohol acrylate, 10 parts of trimethylol cyclohexyl acrylate, 8 parts of bisphenol fluorene acrylate, 3 parts of organic-inorganic hybrid acrylate, 0.5 parts of antioxidant, 2 parts of initiator, and 1 part of silicone additive.

[0036] The organic-inorganic hybrid acrylate is nano-silica organic-inorganic hybrid acrylate, nano-titanium dioxide organic-inorganic hybrid acrylate and nano-zirconia organic-inorganic hybrid acrylate.

[0037] The preparation method of the nano-silica organic-inorganic hybrid acrylate or nano-zirconia organic-inorganic hybrid acrylate is: mixing acrylate resin, nano-silica sol / nano-titania sol / nano-zirconia sol , and stirred for 2 hours to obtain nano-silica organic-inorganic hybrid acrylate or nano-zirconia organic-inorganic hybrid acrylate...

Embodiment 3

[0042] An optical adhesive comprising the following components in parts by weight: 30 parts of o-phenylphenoxyethyl acrylate, 20 parts of ethoxylated bisphenol A dimethacrylate, 10 parts of tetrahydrofurfuryl alcohol acrylate, 10 parts of trimethylol cyclohexyl acrylate, 8 parts of bisphenol fluorene acrylate, 3 parts of organic-inorganic hybrid acrylate, 0.5 parts of antioxidant, 2 parts of initiator, and 1 part of silicone additive.

[0043] The antioxidant is three (4-tert-butyl-3-hydroxy-2,6-dimethylbenzyl) isocyanuric acid and tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl ) propionate] pentaerythritol ester. The organosilicon additive is KH560. The initiator is 2-hydroxy-2-methyl-1-phenyl-1-propanone.

[0044] The organic-inorganic hybrid acrylate is nano-silica organic-inorganic hybrid acrylate, nano-titanium dioxide organic-inorganic hybrid acrylate and nano-zirconia organic-inorganic hybrid acrylate.

[0045] The preparation method of the nano-silica organic-inorga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com