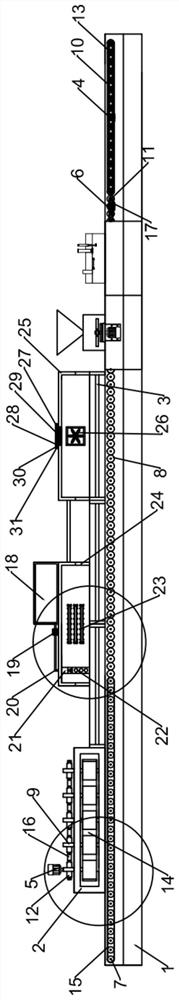

Automatic can production line

A production line and canned food technology, applied in the field of automatic canned food production line, can solve the problems of inability to transport cans, no way to transport and weigh cans, waste of resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

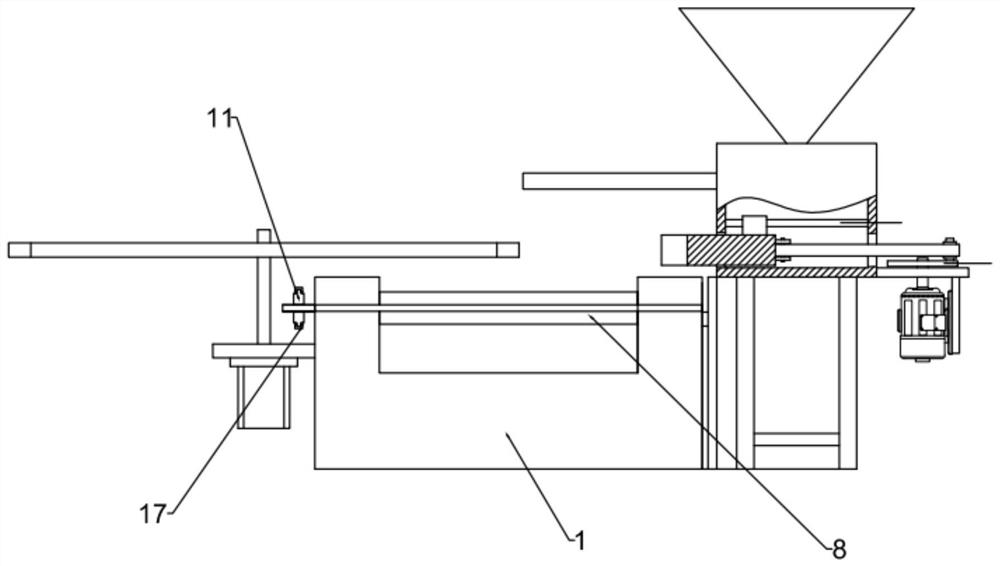

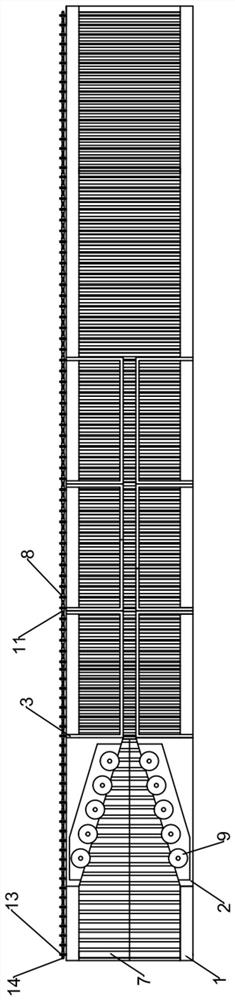

[0032]Embodiment: run by the transport belt driver 4 on the transport platform 1, drive the transport drum 7 on the transport belt 15 transport drive machine 6 drive end to rotate, drive the transport belt sprocket 10 on it to rotate by the transport drum 7, pass a The conveyor belt sprockets 10 drive the conveyor belt chains 13 on it to rotate respectively, drive several conveyor belt sprockets 10 on it to rotate by a pair of conveyor belt chains 13, and drive the conveyor belt sprockets 10 on it by several conveyor belt sprockets 10 respectively. The transport roller 7 rotates, and the transport belt 15 on it is driven by several transport rollers 7 respectively, and the can shells on it are respectively driven by a pair of transport belt 15, and the pair of transport side walls on a pair of triangular side wall brackets 2 are simultaneously The driving machine 5 runs, respectively drives the transport side wall shaft 9 on the driving end of a pair of transport side wall driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com