Antibacterial and antiviral ferritic stainless steel and preparation method thereof

A ferritic and stainless steel technology, applied in the direction of manufacturing tools, heat treatment equipment, furnace types, etc., can solve the problems of antibacterial performance decline, etc., and achieve the effect of equivalent corrosion resistance, excellent mechanical properties and high plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A kind of preparation method of antibacterial toxic ferritic stainless steel of the present invention comprises the following steps:

[0034] a. Weigh raw materials according to the following mass percentage: C: 0.06~0.08%, Si≤0.50%, Mn≤1.0%, S≤0.020%, P≤0.030%, Cr: 16.5~17.5%, Ni≤0.60%, N ≤0.1%, Ag: 0.01~0.06%, RE: 0.010~0.045, the rest is iron and unavoidable impurities; wherein RE is at least one rare earth element among La and Ce;

[0035]b. The raw materials taken in step a are pretreated by molten iron, primary smelting furnace (electric arc furnace, AOD smelting, induction furnace), refining outside the furnace, continuous casting (forging), hot rolling (cold rolling) process to obtain stainless steel plates, rods and wires of required specifications; after continuous casting (forging) and hot rolling (cold rolling), an annealing process is set up respectively, and annealing treatment is performed after cold rolling, and finally antibacterial and poisonous ferrit...

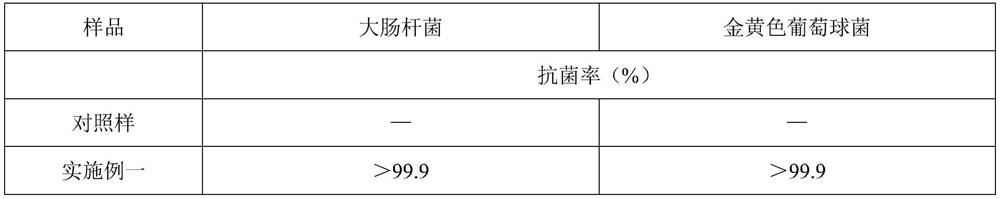

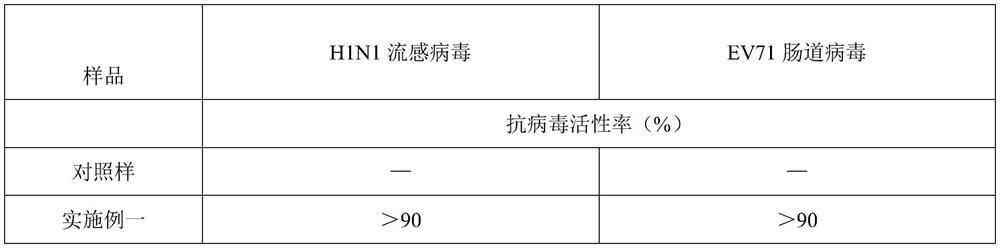

Embodiment 1

[0046] Embodiment 1: In this embodiment, an antibacterial and poisonous ferritic stainless steel, the chemical composition of which is shown in Table 1.

[0047] In this embodiment, the preparation method of antibacterial and poisonous ferritic stainless steel of this embodiment includes the following steps:

[0048] a. Weigh the raw materials according to the prepared target stainless steel component mass percentage with the composition of Table 1:

[0049] C:0.07%, Si:0.27%, Mn:0.40%, S:0.001%, P:0.012%, Cr:17.00%, Ni:0.20%, N:0.06%, Ag:0.030%, La+Ce:0.017 %, the rest is iron and unavoidable impurities;

[0050] b. The raw materials taken in the step a are subjected to a series of processes of molten iron pretreatment, AOD refining, LF refining, continuous casting, hot rolling, and cold rolling to obtain stainless steel plates of required thickness; After the cold rolling, an annealing process is set respectively, and after the cold rolling, the annealing treatment is carr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com