Bionic gradient antifouling composite coating and preparation method thereof

A composite coating and gradient technology, which is applied in coating, metal material coating process, fusion spraying, etc., can solve the problems of insufficient toughness, improve toughness and bonding strength, avoid frequent powder replacement, and improve coating consistency. effect of density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

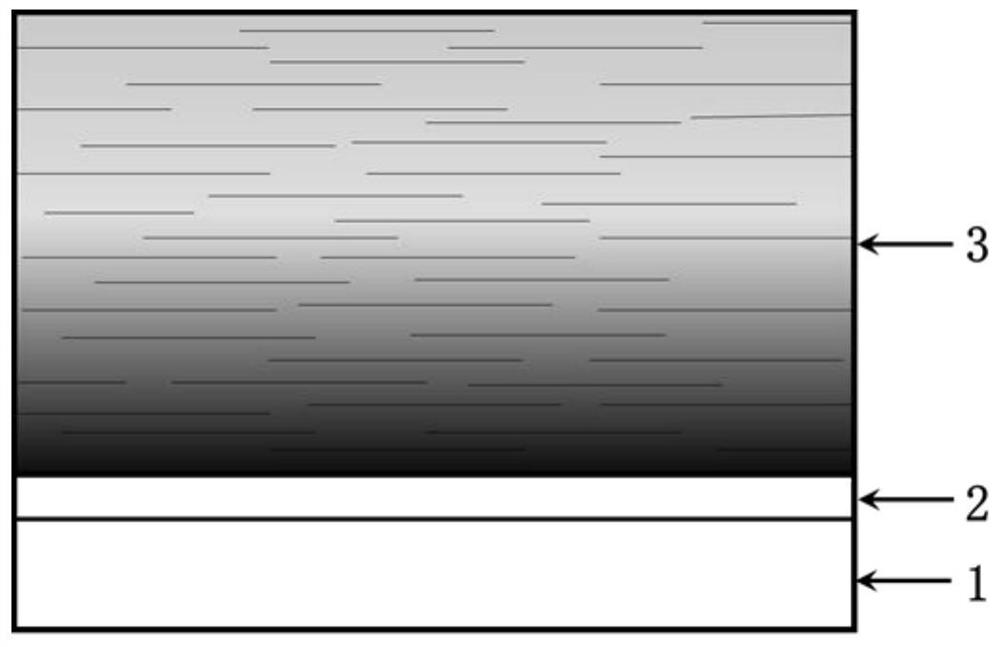

[0024] Such as figure 1 As shown, in this embodiment, a dense bonding layer is deposited on the metal substrate, and a dense gradient composite coating is deposited on the surface of the bonding layer.

[0025] In this embodiment, the material of the metal base is 45 steel.

[0026] In this embodiment, the composition of the bonding layer is NiCrAl; the composition of the gradient composite coating is Al 2 o 3 -13%TiO 2 , Modified NiCrAlY, navy copper HSn70-1.

[0027] In this embodiment, the thickness of the bonding layer is 100 μm, and the thickness of the gradient composite coating is 400 μm.

[0028] combine figure 1 , a preparation method of bionic gradient antifouling composite coating, comprising the following steps:

[0029] Step 1, use coarse sandpaper (100#) to polish the surface of the metal substrate sample, then use alcohol to clean, sandblast the sample, install the sample after alcohol ultrasonic cleaning;

[0030] Step 2, using a gas mask to protect the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com