Electrical insulation ultrahigh-voltage epoxy resin composition and preparation method thereof

An epoxy resin and electrical insulation technology, applied in the field of epoxy resin, can solve problems such as product cracking, affecting the service life of epoxy resin insulation parts, epoxy resin electrical aging resistance and breakdown strength reduction, and achieve vitrification Increased temperature, good insulation effect, effect of reducing stress cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

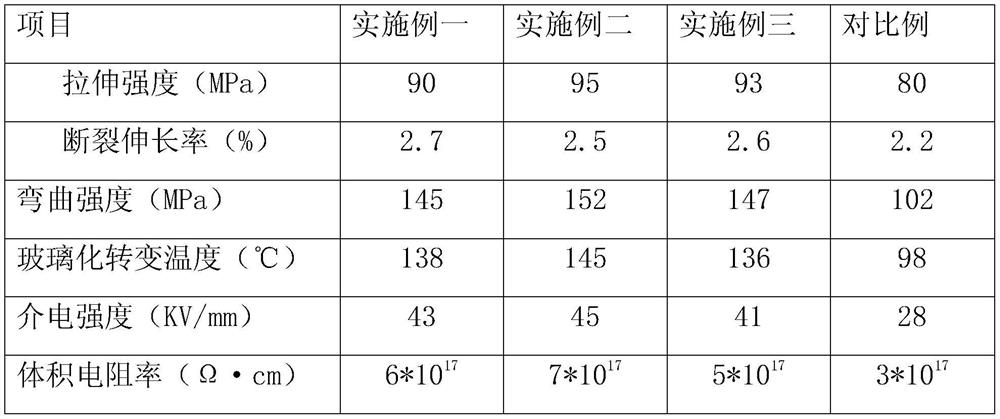

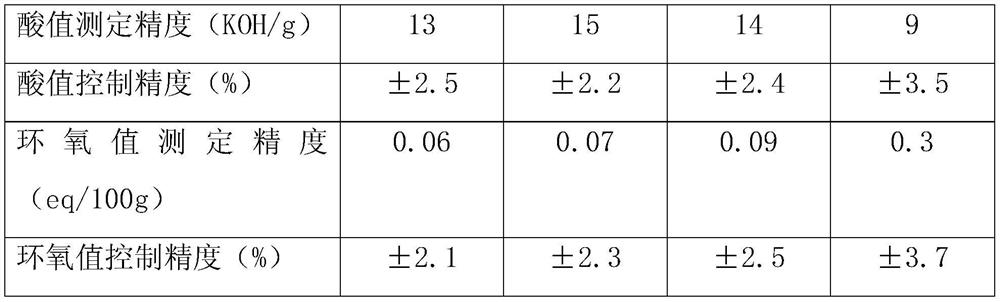

Examples

Embodiment 1

[0018] An electrical insulating ultra-high voltage epoxy resin composition, comprising the following components in parts by weight: 100 parts of epoxy resin, 100 parts of curing agent, 20 parts of polysulfide rubber, 20 parts of urea melamine formaldehyde resin, and 20 parts of phenolic resin , 20 parts of isocyanate, 20 parts of polytetrafluoroethylene, 20 parts of inorganic nano-mixture, 10 parts of toughening agent.

[0019] The toughening agent is polyethersulfone.

[0020] The curing agent is an acid anhydride curing agent.

[0021] Inorganic nano-mixtures include porcelain powder and alumina.

[0022] The ratio of porcelain powder and alumina is 1:1.

[0023] The D50 particle size of the inorganic nano-mixture is 50nm.

[0024] A preparation method of an electrical insulation ultra-high voltage epoxy resin composition, comprising the following steps:

[0025] S1. Put the epoxy resin, polysulfide rubber, urea melamine formaldehyde resin, phenolic resin, isocyanate, po...

Embodiment 2

[0029] An electrical insulating ultra-high voltage epoxy resin composition, comprising the following components in parts by weight: 150 parts of epoxy resin, 100 parts of curing agent, 20 parts of polysulfide rubber, 25 parts of urea melamine formaldehyde resin, and 30 parts of phenolic resin , 35 parts of isocyanate, 40 parts of polytetrafluoroethylene, 25 parts of inorganic nano-mixture, 15 parts of toughening agent.

[0030] The toughening agent is a combination of polyethersulfone and polyimide, and the combination ratio is 1:1.

[0031] The curing agent is an acid anhydride curing agent.

[0032] Inorganic nano-mixtures include porcelain powder and alumina.

[0033] The ratio of porcelain powder and alumina is 1:2.

[0034] The D50 particle size of the inorganic nano-mixture is 75nm.

[0035] A preparation method of an electrical insulation ultra-high voltage epoxy resin composition, comprising the following steps:

[0036] S1. Put the epoxy resin, polysulfide rubber,...

Embodiment 3

[0040] An electrical insulation ultra-high voltage epoxy resin composition, comprising the following components in parts by weight: 200 parts of epoxy resin, 150 parts of curing agent, 40 parts of polysulfide rubber, 20 parts of urea melamine formaldehyde resin, 40 parts of phenolic resin , 20 parts of isocyanate, 40 parts of polytetrafluoroethylene, 30 parts of inorganic nano-mixture, 20 parts of toughening agent.

[0041] The toughening agent is polyimide.

[0042] The curing agent is an acid anhydride curing agent, which can be a single-component acid anhydride curing agent or a mixture of multi-component acid anhydride curing agents. A mixture of two or at least three kinds, the addition of the above-mentioned acid anhydrides can fully react the hydroxyl groups in the epoxy resin, increase the crosslinking degree of the epoxy resin, and improve the physical properties of the epoxy resin composition.

[0043] Inorganic nano-mixtures include porcelain powder and alumina.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com