A wear-resistant gradient interface multiphase reinforced titanium alloy material and its preparation method

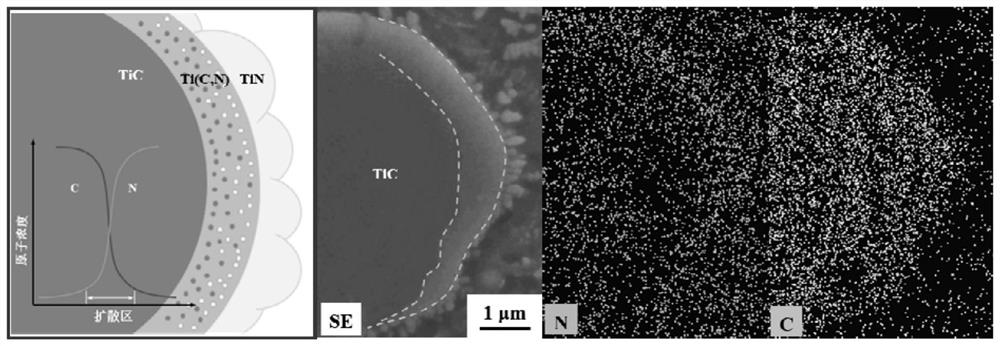

An alloy material and titanium alloy technology, which is applied in the field of wear-resistant gradient interface multiphase reinforced titanium alloy material and its preparation, can solve the problems of poor interface bonding between ceramic reinforcement and matrix, difficult size and shape control, and poor interface bonding. , to achieve the effect of improving the forming quality and mechanical properties, improving the forming quality and performance, and improving the interface bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

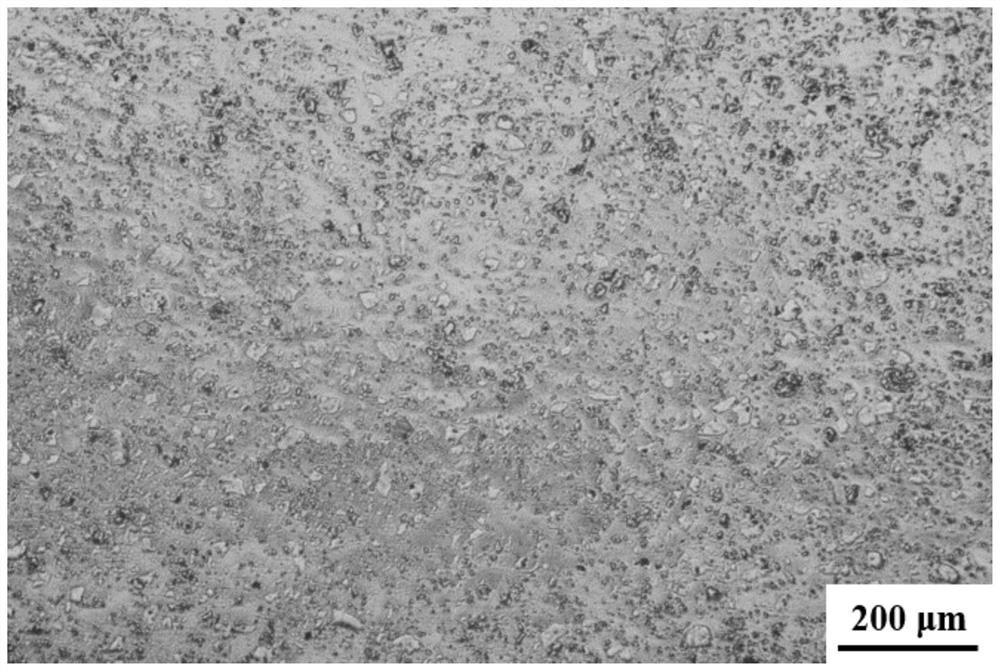

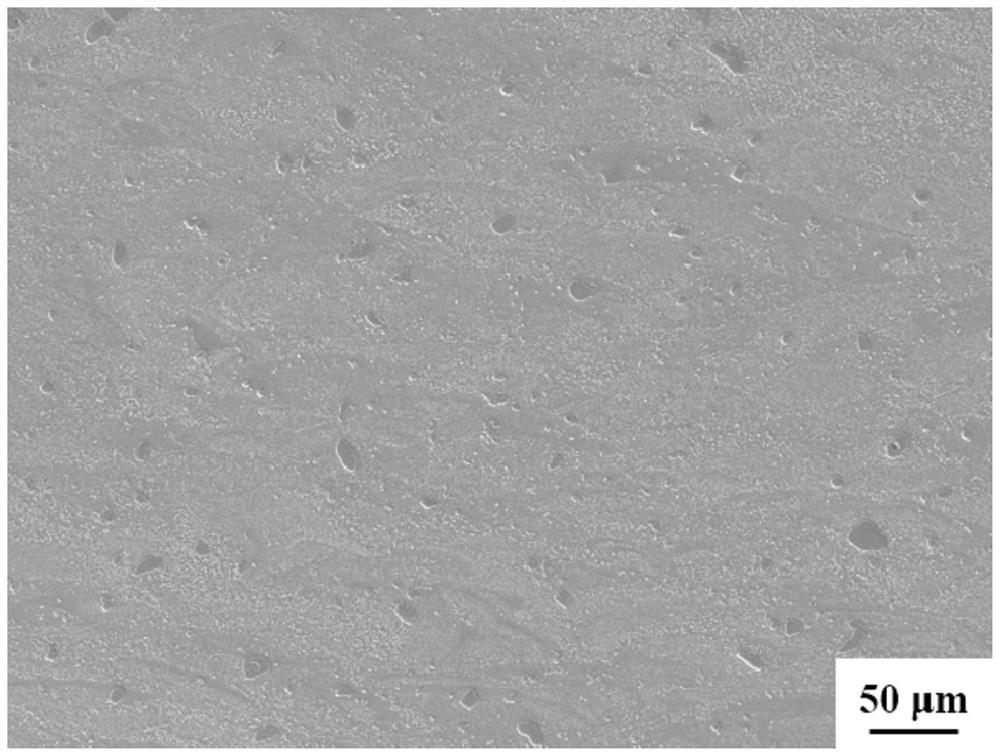

[0039] (1) TiC ceramic powder and TiN ceramic powder are mixed with titanium-aluminum-molybdenum-vanadium-zirconium metal powder according to the ratio of 15wt.% each (the percentage of the total mass of the alloy material), and ball milling is carried out to prepare 30wt% TiC+TiN / Titanium-aluminum-molybdenum-vanadium-zirconium composite powder. Use QM series planetary ball mill for ball milling and powder mixing operation. The process uses stainless steel tanks, and the ball milling medium is stainless steel balls with diameters of 6mm, 8mm and 10mm. The parameters of the ball milling process are set as follows: the ball-to-material ratio is 2:1, the ball milling speed is 250rpm, and the ball milling time is 4h. At the same time, in order to prevent the temperature in the ball mill tank from being too high, the equipment operation mode is interval type during ball milling, that is, the equipment will stop air cooling for 5 minutes after every 15 minutes of operation. The b...

Embodiment 2

[0047] (1) Mix TiC and TiN ceramic powder with titanium-aluminum-molybdenum-vanadium-zirconium metal powder according to the ratio of 12.5wt.% each, and perform ball milling to prepare 25wt% TiC+TiN / titanium-aluminum-molybdenum-vanadium-vanadium- Zirconium composite powder. Use QM series planetary ball mill for ball milling and powder mixing operation. The process uses stainless steel tanks, and the ball milling medium is stainless steel balls with diameters of 6mm, 8mm and 10mm. The parameters of the ball milling process are set as follows: the ball-to-material ratio is 2:1, the ball milling speed is 300rpm, and the ball milling time is 5h. At the same time, in order to prevent the temperature in the ball mill tank from being too high, the equipment operation mode is interval type during ball milling, that is, the equipment will stop air cooling for 5 minutes after every 15 minutes of operation. The ball milling process needs to be carried out under the protection of argon t...

Embodiment 3

[0055] (1) Mix TiC and TiN ceramic powder with titanium-aluminum-molybdenum-vanadium-zirconium metal powder according to the ratio of 11wt.% each, and perform ball milling to prepare 22wt% TiC+TiN / titanium-aluminum-molybdenum-vanadium-zirconium metal powder Composite powder. Use QM series planetary ball mill for ball milling and powder mixing operation. The process uses stainless steel tanks, and the ball milling medium is stainless steel balls with diameters of 6mm, 8mm and 10mm. The parameters of the ball milling process are set as follows: the ball-to-material ratio is 2:1, the ball milling speed is 400rpm, and the ball milling time is 6h. At the same time, in order to prevent the temperature in the ball mill tank from being too high, the equipment operation mode is interval type during ball milling, that is, the equipment will stop air cooling for 5 minutes after every 15 minutes of operation. The ball milling process needs to be carried out under the protection of argon ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com