Extra-high voltage resistant insulating resin and preparation method thereof

An insulating resin and high-voltage technology, which is applied in the field of insulating resin, can solve the problems of epoxy resin mechanical properties, electrical aging resistance and breakdown strength reduction, affecting the service life of epoxy resin insulating parts, and discharge breakdown products. To achieve excellent electrical insulation performance, increase the glass transition temperature and insulation performance, and improve the effect of insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

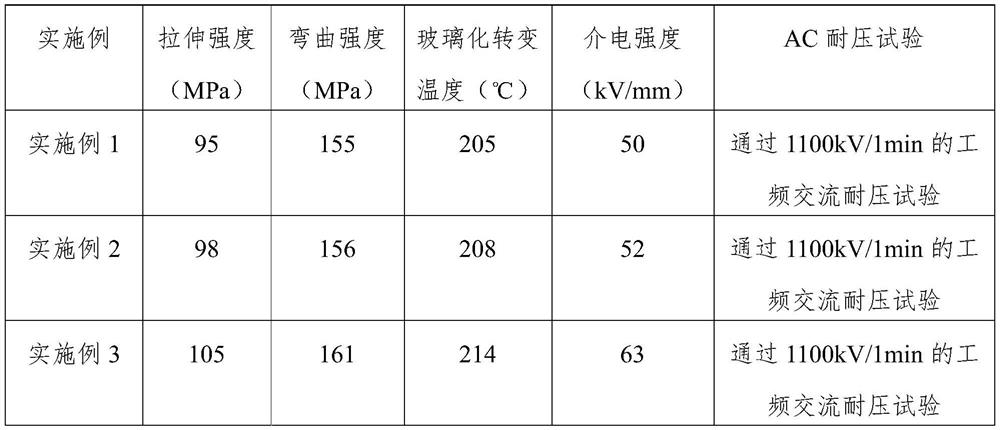

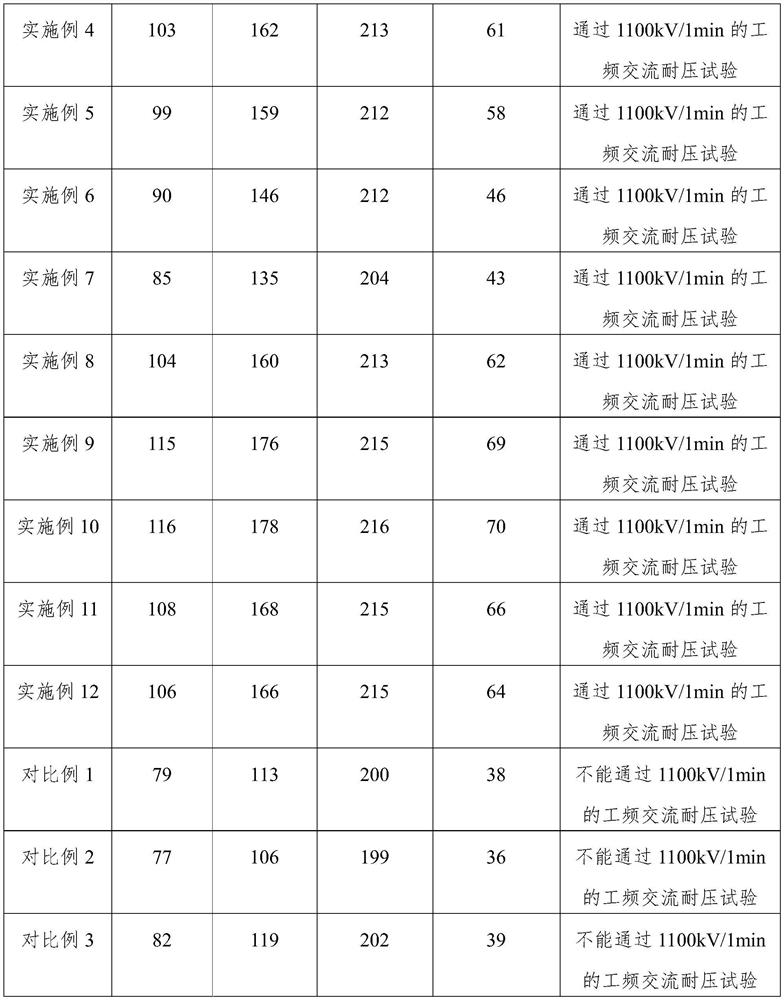

Examples

preparation example Construction

[0032] In a first aspect, the present invention provides a method for preparing an ultra-high voltage insulating resin, the preparation method comprising the following steps:

[0033] (1) 40-68 parts by weight (for example, 40, 41, 42, 43, 44, 45, 46, 47, 48, 49, 50, 51, 52, 53, 54, 55, 56, 57, 58, 59 , 60, 61, 62, 63, 64, 65, 66, 67 or 68 parts by weight) of the matrix resin and 5 to 15 parts by weight (for example, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14 or 15 parts) toughening agent mixed, then inert gas (such as N 2 ) under the protection of 60 ~ 100 ℃ (such as 60 ℃, 65 ℃, 70 ℃, 75 ℃, 80 ℃, 85 ℃, 90 ℃, 95 ℃ or 100 ℃) stirring for 1 ~ 3h (such as 1, 1.5, 2, 2.5 or 3h) to obtain a toughened matrix resin; in the present invention, the mass ratio of the matrix resin to the toughening agent is (40-68): (5-15) (for example, 40:5, 40:6, 40 :7, 40:8, 40:9, 40:10, 40:11, 40:12, 40:13, 40:14, 40:15, 45:5, 45:6, 45:7, 45:8 , 45:9, 45:10, 45:11, 45:12, 45:13, 45:14, 45:15, 50:5, 50:6, 50...

Embodiment 1

[0070] Step 1: Preparation of toughened matrix resin

[0071] After mixing 50 parts of phenolic modified epoxy resin (bisphenol F type epoxy resin F-44) and 5 parts of toughener liquid polysulfide rubber (JLY-121 liquid polysulfide rubber), start stirring, and the stirring speed is 200r / min, at the same time, pass N 2 , heated to 80°C, and stirred for 2 hours; after stirring, a toughened matrix resin was obtained.

[0072] Step 2: Preparation of Ceramic Additive Dispersion

[0073] The boron nitride particles with an average particle size of 2 μm and ethanol were added to the ball mill in a mass ratio of 2:8, and the ball mill was carried out by a planetary ball mill. The speed of the ball mill was controlled at 400 rpm and the ball milling time was 15 hours. In the ceramic additive dispersion liquid, the mass percentage content of boron nitride particles in the ceramic additive dispersion liquid is 20% (corresponding to 10 parts of the ceramic additive).

[0074] Step 3: ...

Embodiment 2

[0082] Step 1: Preparation of toughened matrix resin

[0083] After mixing 68 parts of bisphenol F-type epoxy resin F-44 with 15 parts of toughener liquid polysulfide rubber (JLY-121 liquid polysulfide rubber), start stirring, and the stirring speed is 200r / min. 2 , heated to 80°C, and stirred for 2 hours; after stirring, a toughened matrix resin was obtained.

[0084] Step 2: Preparation of Ceramic Additive Dispersion

[0085] The boron nitride particles with an average particle size of 2 μm and ethanol were added to the ball mill in a mass ratio of 2:8, and the ball mill was carried out with a planetary ball mill. The speed of the ball mill was controlled at 400 rpm, and the ball milling time was 15 hours. In the ceramic additive dispersion, the mass percentage content of boron nitride particles in the ceramic additive dispersion is 20% (corresponding to 20 parts of the ceramic additive).

[0086] Step 3: Preparation of a mixture of ceramic additive dispersion, toughened m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com