Preparation method of MOF-derived CoP hydrogen evolution catalyst

A catalyst and hydrogen evolution technology, applied in the direction of electrolysis components, electrodes, electrolysis process, etc., to achieve the effects of easy scale-up and industrial production, good conductivity and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

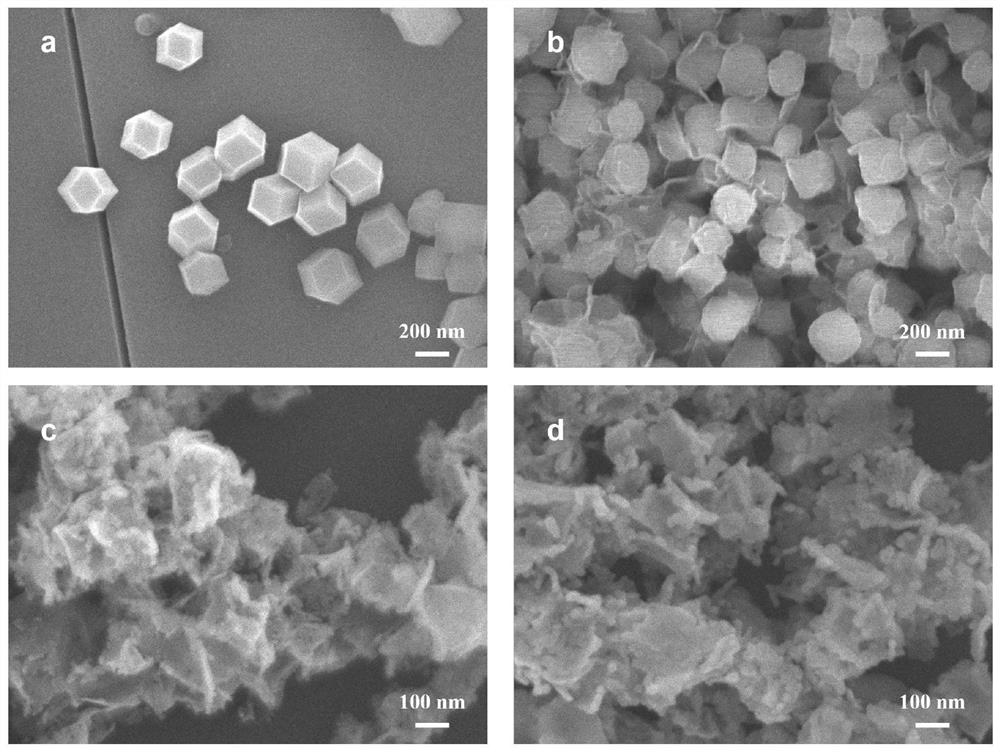

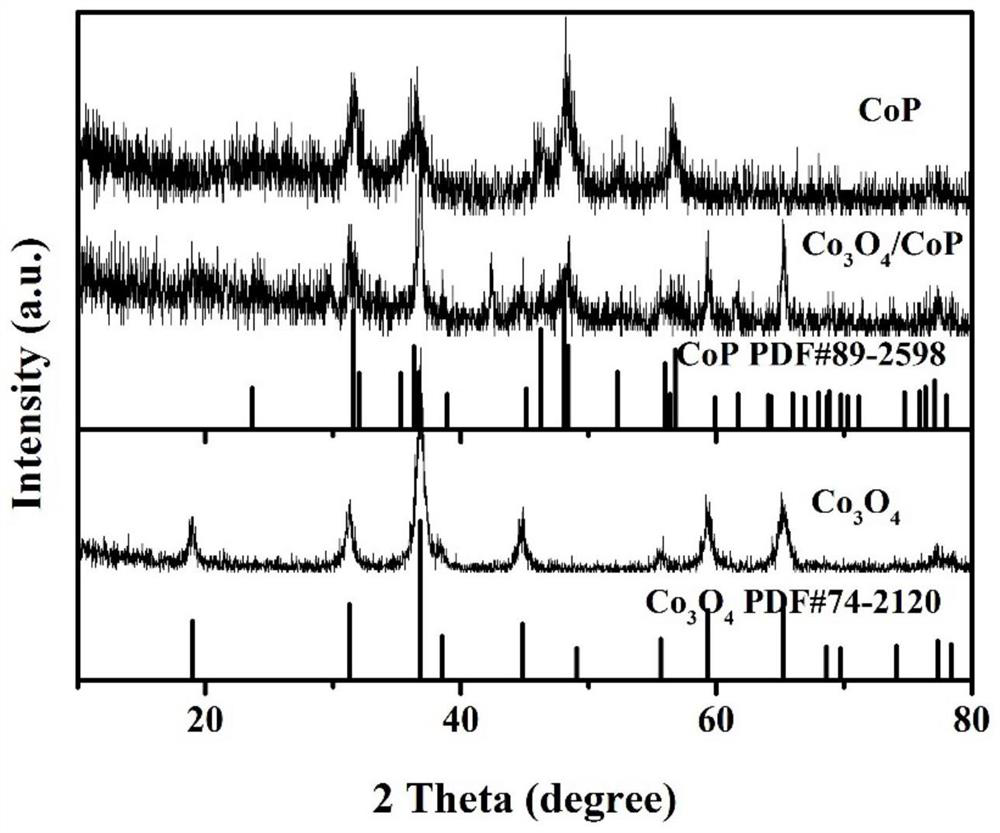

Embodiment 1

[0012] Weigh 2.05g of 2-methylimidazole and dissolve in 50mL of anhydrous methanol, and dissolve 0.703g of cobalt nitrate hexahydrate in 50mL of anhydrous methanol. After mixing evenly, sonicate for 30min, let stand for 18h and then centrifuge to generate ZIF-67 nanoparticles. (2) After 0.1 g of ZIF-67 and 0.1 g of cobalt nitrate hexahydrate were dissolved in 50 mL of ethanol, the mixture was refluxed and stirred in an oil bath at 90 °C for 1 h, then centrifuged with ethanol several times and dried at 60 °C to obtain ZIF-67@Co. (3) The obtained ZIF-67@Co was air-fired at a heating rate of 2°C / min, kept at 120°C for 1 hour, and kept at 350°C for 2 hours to obtain tricobalt tetroxide. (4) Phosphating treatment was carried out in a tube furnace at a heating rate of 2°C / min, 1h at 120°C and 1h at 350°C to obtain a MOF-derived CoP hydrogen evolution catalyst.

Embodiment 2

[0014] Weigh 2.05g of 2-methylimidazole and dissolve in 50mL of anhydrous methanol, and dissolve 0.703g of cobalt nitrate hexahydrate in 50mL of anhydrous methanol. After mixing evenly, sonicate for 30min, let stand for 18h and then centrifuge to generate ZIF-67 nanoparticles. (2) After 0.1 g of ZIF-67 and 0.1 g of cobalt nitrate hexahydrate were dissolved in 50 mL of ethanol, the mixture was refluxed and stirred in an oil bath at 90 °C for 1 h, then centrifuged with ethanol several times and dried at 60 °C to obtain ZIF-67@Co. (3) Phosphating treatment was carried out in a tube furnace with a heating rate of 2°C / min, 120°C for 1h, and 350°C for 1h to obtain Co-MOF / CoP.

Embodiment 3

[0016] Weigh 2.05g of 2-methylimidazole and dissolve in 50mL of anhydrous methanol, and dissolve 0.703g of cobalt nitrate hexahydrate in 50mL of anhydrous methanol. After mixing evenly, sonicate for 30min, let stand for 18h and then centrifuge to generate ZIF-67 nanoparticles. (2) The obtained ZIF-67 nanoparticles were air-fired at a heating rate of 2°C / min, kept at 120°C for 1 hour, and kept at 350°C for 2 hours to obtain tricobalt tetroxide. (4) Perform phosphating treatment in a tube furnace with a heating rate of 2°C / min, hold at 120°C for 1 hour, and hold at 350°C for 1 hour to obtain Co 3 o 4 / CoP.

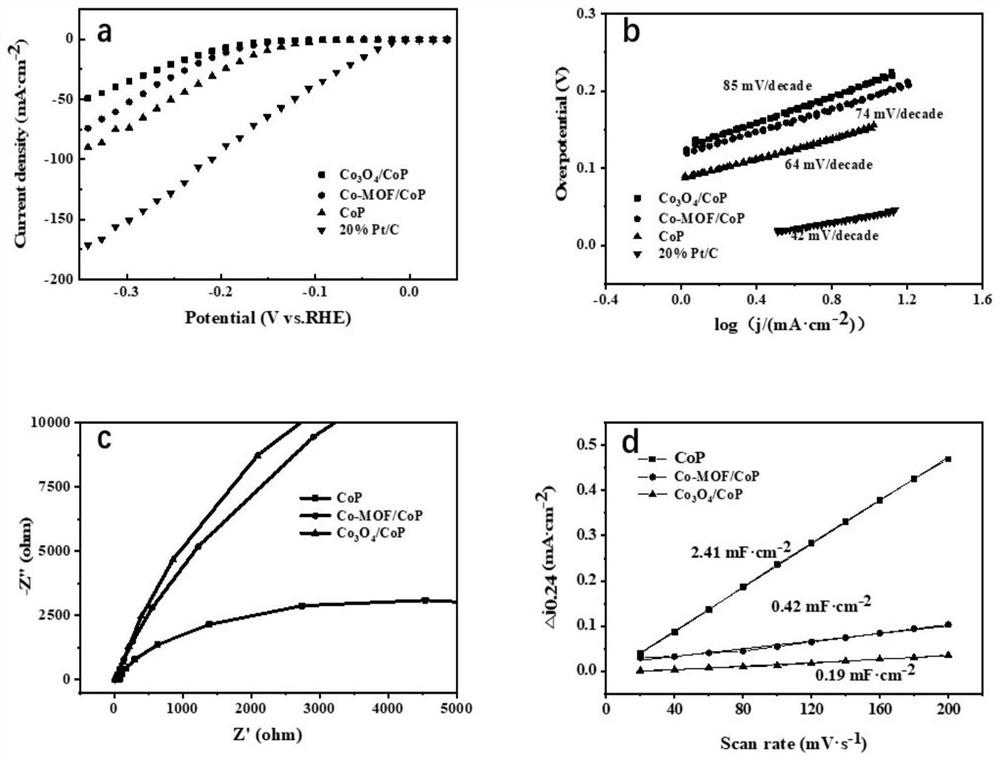

[0017] From the test results of the MOF-derived CoP hydrogen evolution catalyst obtained in the present invention, the MOF-derived CoP hydrogen evolution catalyst obtained in the present invention has the advantages of high hydrogen evolution activity, good conductivity, and high stability under acidic conditions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com