Processing method of novel light and thin underwear fabric

A technology of underwear fabrics and processing methods, applied in the field of clothing, can solve problems such as poor stretchability, inability to meet anti-wrinkle requirements, and insufficient softness of fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

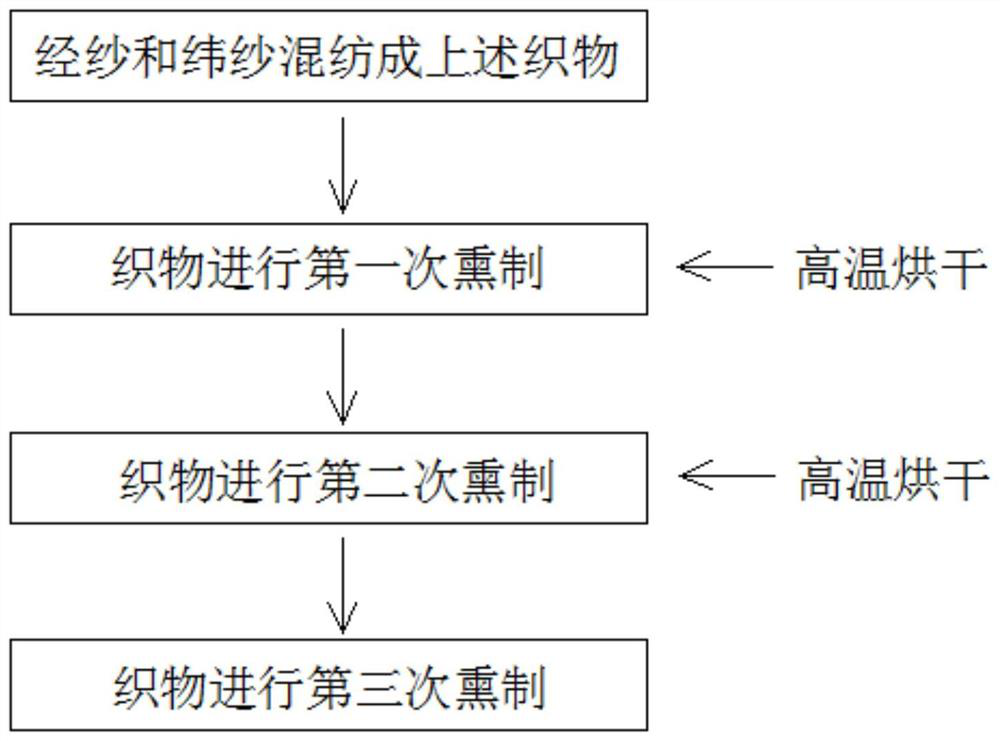

[0048] On the basis of the above structure, in this embodiment, the step S2 specifically includes the following steps:

[0049] S21: spread the fabric on the upper part of the sealed box, and preheat the sealed box to 30-50°C;

[0050] S22: Add fumigant into the sealed box, the liquid level of the fumigant is below the fabric, heat the fumigant to evaporate and generate steam to fumigate the fabric for 30-50 minutes;

[0051] S23: Continue heating the fumigant to 70-95° C., and continue to smoke the fabric for 10-35 minutes.

[0052] In the above scheme, the fabric is laid flat on the top of the sealed box to increase the contact area between the fabric and the fumigant, improve the effect of fabric smoking, and improve the softness and tensile strength of the fabric; in addition, the sealed box is pre-conditioned before the fabric is smoked. Heat treatment prevents the fumigant steam from condensing on the inner wall of the sealed box, makes the fumigant fully contact with t...

Embodiment 2

[0055] On the basis of Embodiment 1, in this embodiment, the step S2 further includes:

[0056] S24: Take out the fabric that has been smoked for the first time, and soak it in a softener for 20-30 minutes.

[0057] The above steps can soften the fabric, make the subsequent fabric treatment agent easier to absorb, and effectively improve the effect of fabric fumigation

[0058] In addition to the above-mentioned embodiment, the above-mentioned step S24 can also adopt a mechanical method, that is, use various soft cloth machines to perform physical treatments such as beating and kneading, so that the relative positions between fibers and between yarns can be changed, thereby improving Its bending rigidity reduces frictional resistance and achieves the purpose of soft touch. But this mode machine directly contacts with fabric, affects the quality of fabric processing; But this application is to soak fabric by softening agent, and the effect of softening is better, has guarantee...

Embodiment 3

[0060]On the basis of Embodiment 2, in this embodiment, the softening agent is fatty acid diethanolamide or polyethylene resin emulsion or mineral oil, and the effect of the above-mentioned softening agent softening the fabric is better, so that the treatment agent for subsequent fabrics is more easily absorbed. Effectively improve the effect of fabric fumigation

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com