Assembled shield segment

A shield segment and assembled technology, which is applied to shaft equipment, shaft lining, tunnel lining, etc., can solve the problems of large transportation volume of shield segments, large amount of steel bars and concrete, waste of raw materials, etc., and simplify the installation steps. , The effect of improving the pressure resistance and improving the installation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

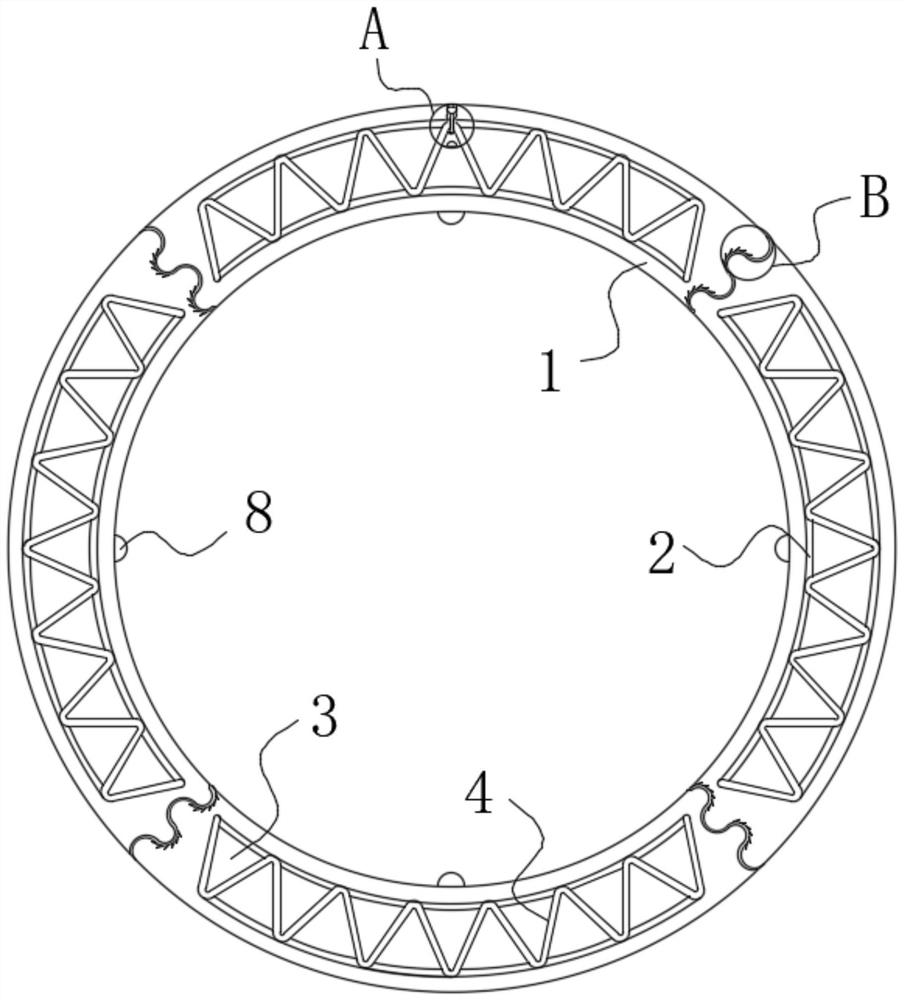

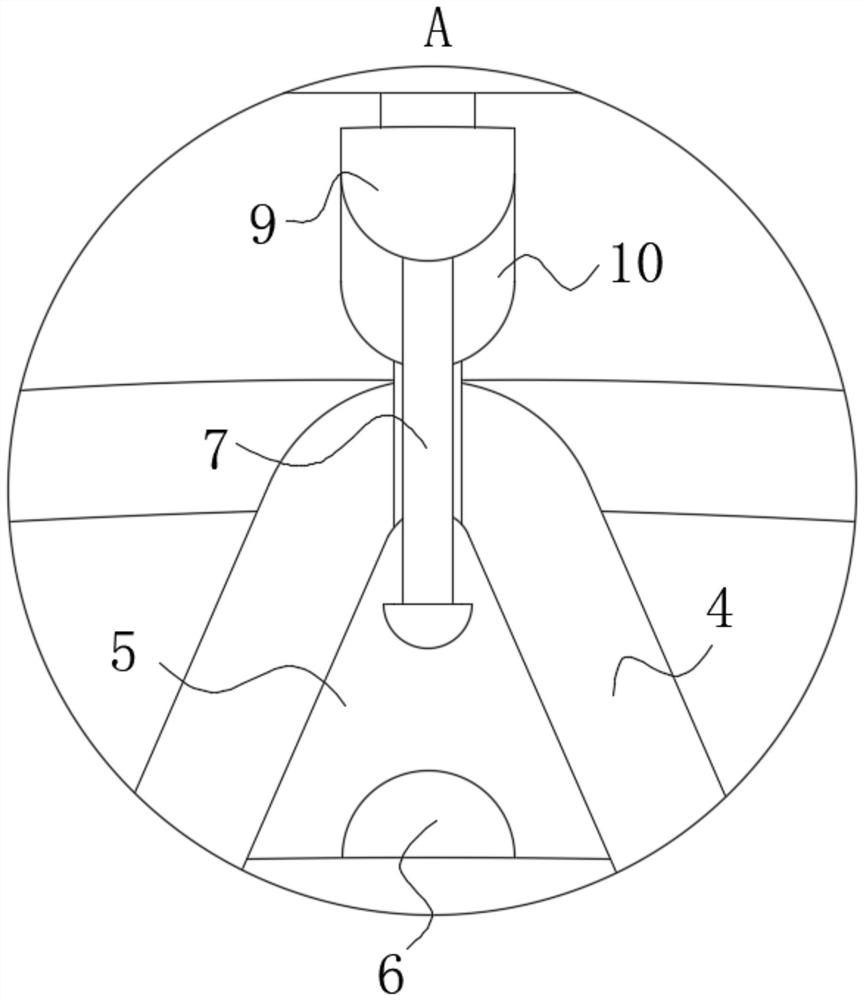

[0020] use Figure 1-Figure 4 An assembled shield segment according to an embodiment of the present invention is described as follows.

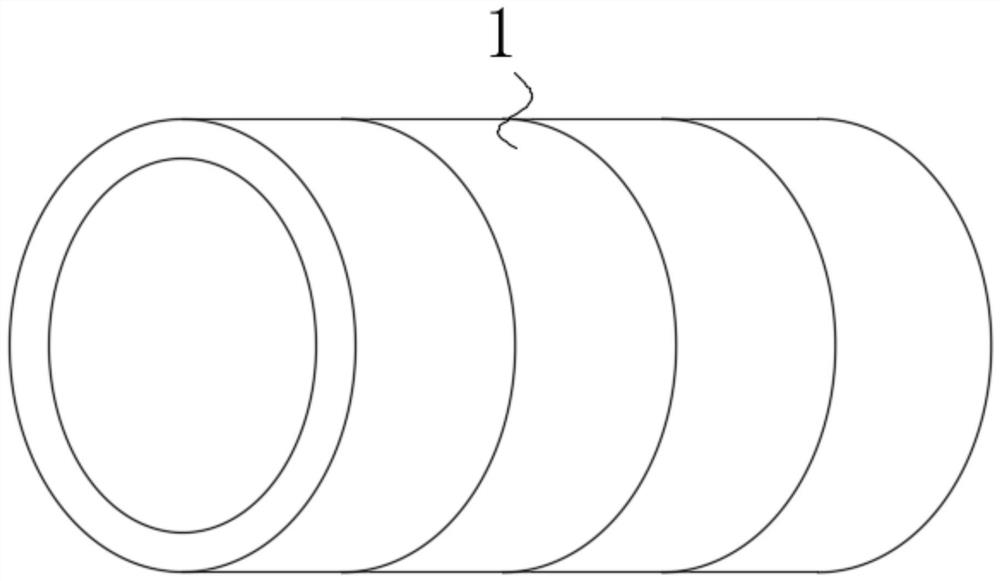

[0021] like Figure 1-Figure 4 As shown, an assembled shield segment according to the present invention includes a plug-in segment 1; the plug-in segment 1 is arranged in an arc shape, and the outer surfaces of both ends of the plug-in segment 1 are set in a wave shape, and the plug-in tube The wavy surfaces of the outer ends of the pieces 1 are assembled in a plug-in manner, and the plug-in tube pieces 1 form a ring shape after the plug-in is completed.

[0022] The inside of the plug-in tube piece 1 is fixedly equipped with a cladding plate 2; the cladding plate 2 is provided with two pieces in the plug-in tube piece 1, and the cladding plate 2 is arranged in an arc shape, and the cladding plate 2 is provided with A certain cavity is filled with flexible concrete 3 in the cavity between the cladding plates 2, wherein the flexible concrete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com