Environment-friendly recyclable air conditioning unit

An air-conditioning unit, an environment-friendly technology, applied in air-conditioning systems, mechanical equipment, shielding with air flow, etc., can solve problems such as waste of resources, achieve the effect of reducing energy loss and compact volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

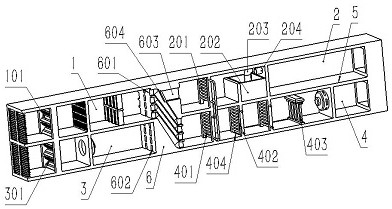

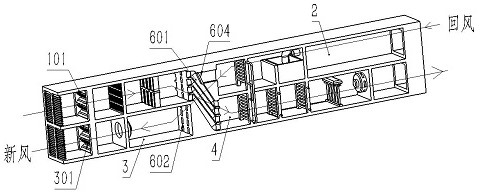

[0031] Embodiment 1, that is, under the normal use state, such as figure 2 As shown, the upper damper 101 is opened, fresh air enters from the first ventilation duct 601, and enters the second lower ventilation cavity 4 through the first ventilation duct 601. At this time, the baffle plate 604 is in an open state, and then it is divided into each room and returned to The wind flows from each room to the second upper ventilation chamber 2, then enters the first lower ventilation chamber 3 through the second ventilation duct 602, and finally is discharged from the opened lower damper 301. Considering the first ventilation duct 601 and the second ventilation duct The second ventilation duct 602 uses heat-conducting materials, and there will be considerable heat exchange between the fresh air and the return air, especially in winter and summer, which can greatly reduce unnecessary energy loss.

Embodiment 2

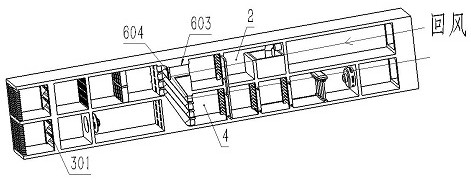

[0032] Embodiment 2, that is, in the loop mode, such as image 3 As shown, the difference from Embodiment 1 is that the baffle 604 is closed and the lower damper 301 is closed. At this time, the return air enters the second lower ventilation cavity from the second upper ventilation cavity 2 through the third ventilation duct 603 4, so that the return air can be recycled. It should be noted that generally the demand for circulating air is not high, especially for the carbon dioxide content. If the carbon dioxide content of the return air is too high, it is recommended to use the first mode. Those skilled in the art can make their own discretion according to the actual situation choose.

[0033] Considering the further exchange of heat between the fresh air and the return air, on the basis of the above-mentioned embodiments, the present invention provides another preferred technical solution, the upper heat exchange tube 201 is fixed in the second upper ventilation chamber 2, an...

Embodiment 3

[0035] Embodiment three, that is, under the state of humidification / dehumidification, such as Figure 4 and 5 As shown, after the fresh air enters the second lower ventilation chamber 4, if the humidity sensor indicates that the humidity is insufficient, the humidifier 403 is turned on to carry out the spray humidification operation; if the humidity sensor indicates that the humidity is too high, the refrigeration device 402 is turned on to allow the air flow Condensate over time and finally gather in the liquid collection pool 404 below. When necessary, the liquid in the liquid collection pool 404 can be pumped to the humidifier 403 for recycling.

[0036]Considering the problem that the carbon dioxide in the return air cannot be recycled when the carbon dioxide is too high, on the basis of the above embodiments, the present invention provides another preferred technical solution, the second upper ventilation cavity 2 is provided with a carbon dioxide removal device, what nee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com