Mirror image manufacturing method and system based on virtual chemical control equipment, and storage medium

A production method and virtualization technology, applied in the direction of program control design, program control device, software simulation/interpretation/simulation, etc., can solve the problems of large number of images, difficult deployment and maintenance, and large number of images to reduce costs , Simplify the mirror image production process and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

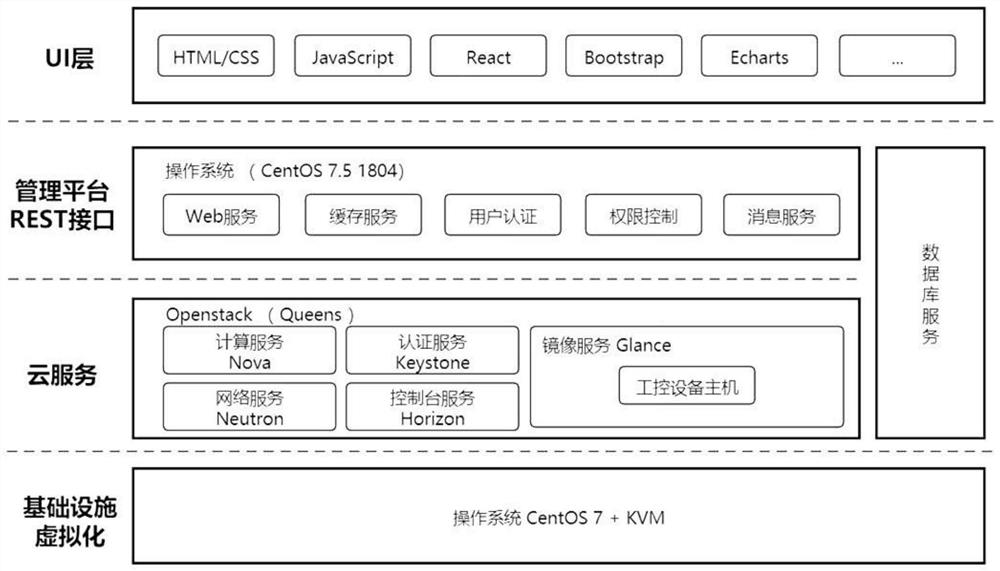

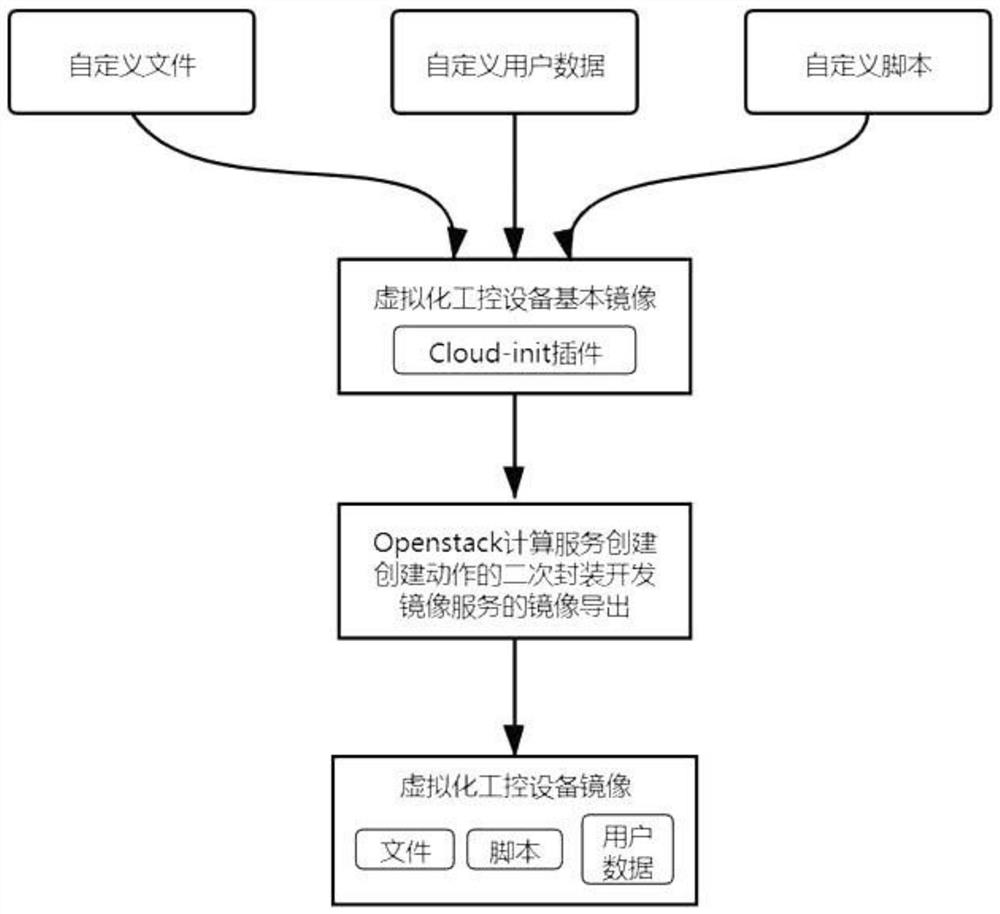

[0019] Such as figure 1 , figure 2 As shown, an image production method based on virtual industrial control equipment includes: based on the built virtual laboratory, installing the cloud-init plug-in on the basis of the basic image of the virtual industrial control equipment; performing secondary packaging and development on computing services to Improve the API interface provided by calling the computing service, realize the cloud-init service connection during the creation process of the computing service based on Openstack; export the virtual chemical control device instance after dynamically loading files and user data through the mirroring service of Openstack, and complete Mirror production.

[0020] The purpose of the virtual laboratory for dynamically constructing the security protection model of the power monitoring system is to design and configure a cloud computing system that provides experiments, teaching, and offensive and defensive drill services for the powe...

Embodiment 2

[0045] Based on the image production method based on virtual industrial control equipment described in Embodiment 1, this embodiment provides an image production system based on virtual industrial control equipment, including a processor and a storage device, and multiple instructions are stored in the storage device is used for the processor to load and execute the steps of the method in Embodiment 1.

Embodiment 3

[0047] Based on Embodiment 1 and Embodiment 2, this embodiment provides a computer-readable storage medium, the computer-readable storage medium includes a stored computer program, wherein when the computer program is executed by a processor, the storage is controlled. The device where the medium is located executes the method described in Embodiment 1.

[0048] Those skilled in the art should understand that the embodiments of the present application may be provided as methods, systems, or computer program products. Accordingly, the present application may take the form of an entirely hardware embodiment, an entirely software embodiment, or an embodiment combining software and hardware aspects. Furthermore, the present application may take the form of a computer program product embodied on one or more computer-usable storage media (including but not limited to disk storage, CD-ROM, optical storage, etc.) having computer-usable program code embodied therein.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com