Method for extracting spice oleoresin under assistance of compound enzyme

An extraction method and spice oil technology, which can be used in food ingredients containing natural extracts, food extraction, food processing, etc., and can solve problems such as limited solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

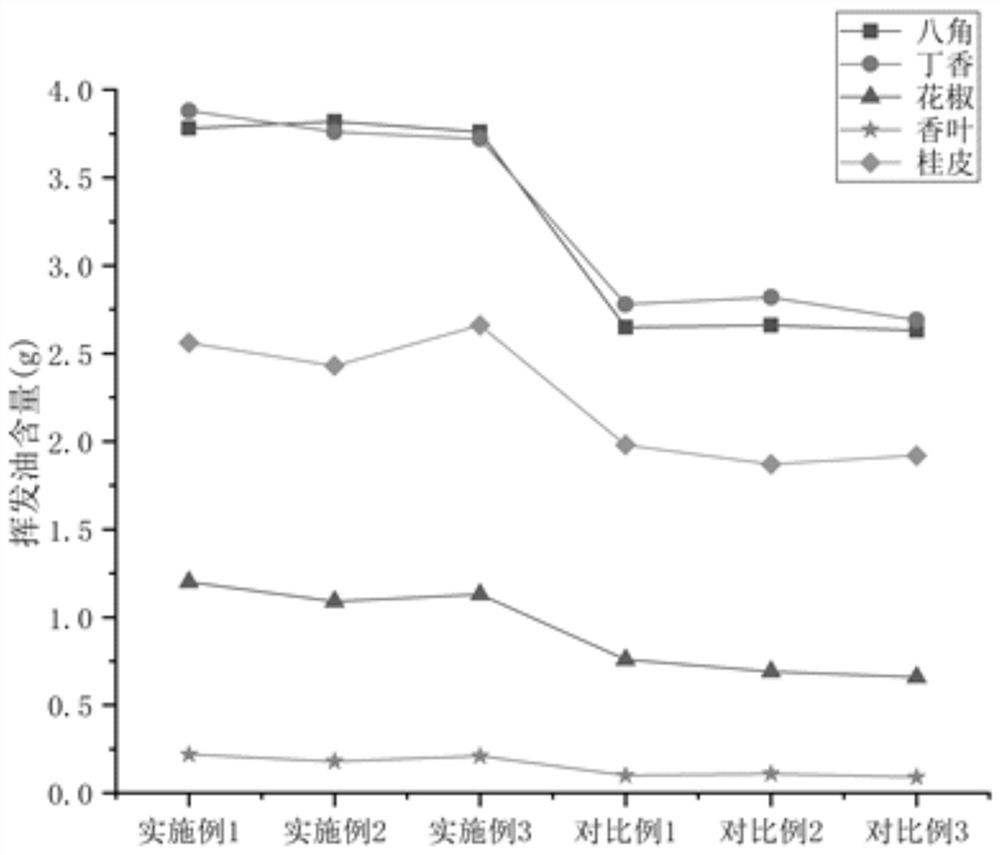

Embodiment 1

[0030] A method for compound enzyme-assisted extraction of spice oleoresin

[0031] (1) Raw material pretreatment: crush the dried spices and pass through a 40-mesh sieve to obtain spice powder for later use;

[0032] (2) Enzymatic hydrolysis treatment: Weigh the spice powder and add distilled water according to the ratio of material to liquid 1: 10 (w:v), and add a compound enzyme with 3% of the mass of spice powder, and control the enzymatic hydrolysis temperature at 45°C, pH value at 5.5 and time at 0.5 h, carry out enzymolysis in an airtight container to obtain the spice enzymolysis solution, for subsequent use;

[0033] (3) Supercritical CO 2 Extraction: Put the spice enzymatic solution obtained in step (2) into a 1L extraction tank, set the extraction temperature to 35°C, extraction pressure to 30Mpa, CO 2 With a flow rate of 60 L / h and an extraction time of 2 h, the product was collected from the splitter.

Embodiment 2

[0035] A method for compound enzyme-assisted extraction of spice oleoresin

[0036] (1) Raw material pretreatment: crush the dried spices and pass through a 40-mesh sieve to obtain spice powder for later use;

[0037] (2) Enzymatic hydrolysis treatment: Add the spice powder obtained in step (1) to distilled water at a material-to-liquid ratio of 1:10 (w:v), and add a compound enzyme with 2% of the spice powder mass, and control the enzymatic hydrolysis temperature at 40°C and pH Value 5 and time 1h, carry out enzymolysis in airtight container, obtain spices enzymolysis solution, set aside;

[0038] (3) Supercritical CO 2 Extraction: Put the spice enzymatic solution obtained in step (2) into a 1L extraction tank, set the extraction temperature to 40°C, extraction pressure to 30Mpa, CO 2 With a flow rate of 60 L / h and an extraction time of 2 h, the product was collected from the splitter.

Embodiment 3

[0040] A method for compound enzyme-assisted extraction of spice oleoresin

[0041] (1) Raw material pretreatment: crush the dried spices and pass through a 40-mesh sieve to obtain spice powder for later use;

[0042] (2) Enzymatic hydrolysis treatment: add the spice powder obtained in step (1) into distilled water at a material-to-liquid ratio of 1:10 (w:v), and add a compound enzyme with 1% of the spice powder mass, and control the enzymatic hydrolysis temperature at 40°C and pH Value 4.5 and time 1.5h, carry out enzymolysis in an airtight container to obtain spice enzymolysis solution, set aside;

[0043] (3) Supercritical CO 2 Extraction: Put the spice enzymatic solution obtained in step (2) into a 1L extraction tank, set the extraction temperature to 30°C, extraction pressure to 25Mpa, CO 2 With a flow rate of 40 L / h and an extraction time of 3 h, the product was collected from the splitter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com