Offshore wind plant steel pipe pile foundation batch floating transportation system and working method thereof

A technology for steel pipe piles and wind farms, which is applied in infrastructure engineering, wind power generation, wind turbine transportation, etc., and can solve problems such as the inability of pluggers to be universal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with accompanying drawing, and its content is explanation of the present invention rather than limitation:

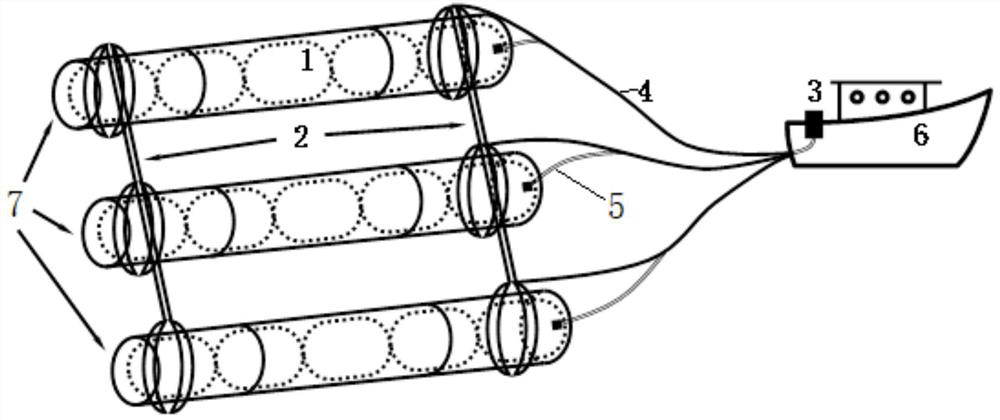

[0036] Such as figure 1 , is the steel pipe pile foundation batch floating system for offshore wind farms of the present invention, including an air bag device 1, a steel pipe pile fixing device 2, an inflator 3, a floating drag cable 4, an inflatable pipe 5 and a vehicle 6.

[0037] A number of steel pipe piles 7 are fixed on the steel pipe pile fixing device 2, and the air bag device 1 is filled in each steel pipe pile 7; the two ends of the floating drag cable 4 are respectively connected with the steel pipe pile fixing device 2 and the carrier 6 ; One end of the inflatable tube 5 is connected to the inflatable device 3, and the other end is connected to each airbag device 1 after branching out a number of branch pipes through a splitter.

[0038] In a preferred embodiment of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com