Self-cleaning passive radiation refrigeration paint as well as preparation method and coating structure thereof

A radiative cooling and self-cleaning technology, used in reflective/signal coatings, coatings, primers, etc., can solve the problems of single, loss of cooling performance, decreased solar reflectance, etc., to achieve high solar reflectance and cooling performance, improve The effect of heat aging resistance and UV aging resistance, and excellent daytime passive radiation cooling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A self-cleaning passive radiative cooling coating, comprising a passive radiative cooling primer and a transparent superhydrophobic self-cleaning topcoat.

[0049] The transparent superhydrophobic self-cleaning topcoat includes in parts by weight: 1 part of nano-hydrophilic nano-silica, 0.2 part of 1M hydrochloric acid, 1 part of tetraethyl orthosilicate, 1 part of hexadecyltrimethoxysilane and 96.8 parts of water . The passive radiative refrigeration primer includes in parts by weight: 30 parts of styrene-acrylic emulsion, 20 parts of nano-calcium carbonate, 20 parts of hollow glass microspheres, 20 parts of silicon dioxide, 5 parts of water, 1 part of dispersant, and 1 part of wetting agent , 1 part of defoamer, 1 part of leveling agent, 1 part of film-forming aid.

[0050] A preparation method of the above coating.

[0051] Weigh nano-hydrophilic silica, 1M hydrochloric acid, ethyl orthosilicate, hexadecyltrimethoxysilane and water according to the formula, and aft...

Embodiment 2

[0059] A self-cleaning passive radiative cooling coating, comprising a passive radiative cooling primer and a transparent superhydrophobic self-cleaning topcoat.

[0060] The transparent superhydrophobic self-cleaning topcoat includes in parts by weight: 2 parts of nano-hydrophilic nano-silica, 0.1 part of 1M hydrochloric acid, 0.5 part of tetraethyl orthosilicate, 2 parts of hexadecyltrimethoxysilane and 95.4 parts of water . The passive radiative refrigeration primer includes in parts by weight: 40 parts of styrene-acrylic emulsion, 13 parts of nano-calcium carbonate, 10 parts of hollow glass microspheres, 10 parts of silicon dioxide, 20 parts of water, 1.4 parts of dispersant, and 1.4 parts of wetting agent , 1.4 parts of defoaming agent, 1.4 parts of leveling agent, and 1.4 parts of film-forming aid.

[0061] A preparation method and coating structure of the above-mentioned passive radiative refrigeration coating are the same as in Example 1.

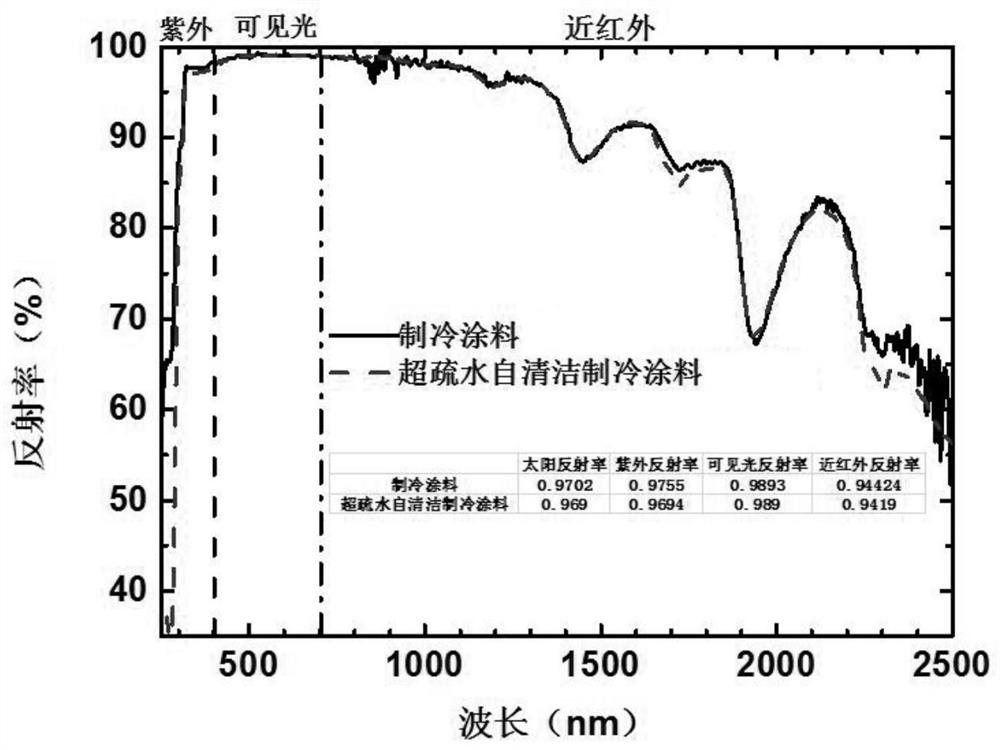

[0062] Figure 5 It is a ...

Embodiment 3

[0066] A self-cleaning passive radiative cooling coating, comprising a passive radiative cooling primer and a transparent superhydrophobic self-cleaning topcoat.

[0067] The transparent superhydrophobic self-cleaning topcoat includes in parts by weight: 1.5 parts of nano-hydrophilic nano-silica, 0.15 parts of 1M hydrochloric acid, 0.75 parts of tetraethyl orthosilicate, 1.5 parts of hexadecyltrimethoxysilane and 96.1 parts of water . The passive radiative refrigeration primer includes in parts by weight: 35 parts of styrene-acrylic emulsion, 10 parts of nano-calcium carbonate, 15 parts of hollow glass microspheres, 15 parts of silicon dioxide, 15 parts of water, 2 parts of dispersant, and 2 parts of wetting agent , 2 parts of defoamer, 2 parts of leveling agent, 2 parts of film-forming aid.

[0068] A preparation method and coating structure of the above-mentioned passive radiative refrigeration coating are the same as in Example 1.

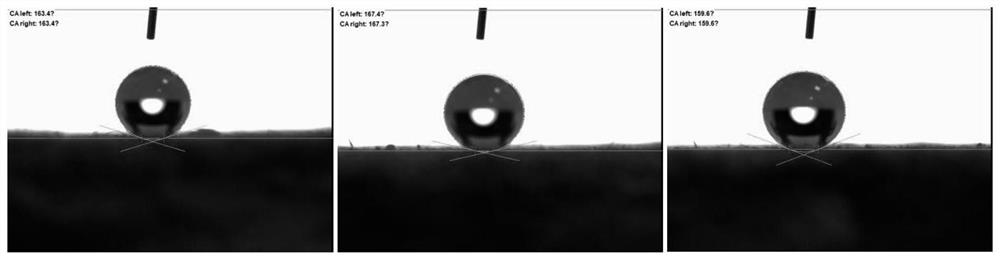

[0069] Figure 8 It is a schematic dia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com