Glass hydrophobic rainproof coating, preparation method thereof, and application method thereof

A coating and hydrophobic technology, applied in coatings and other directions, can solve the problems of easy peeling, poor hydrophobicity, and inability to achieve mass production, and achieve the effect of simple construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

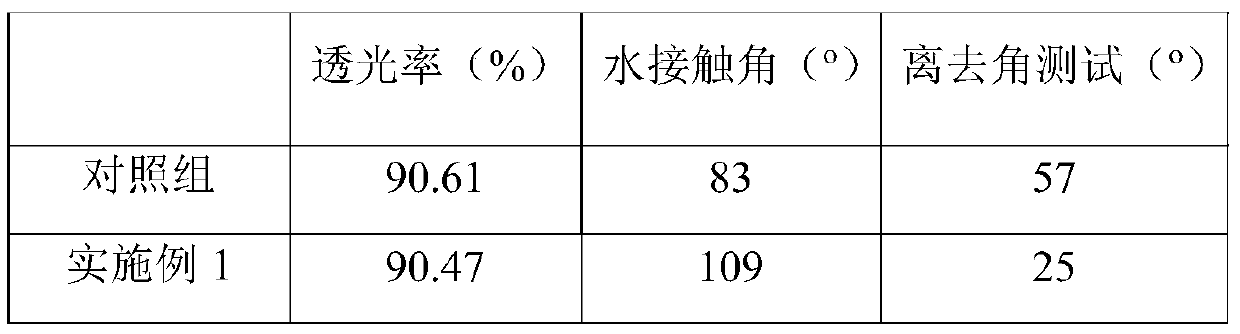

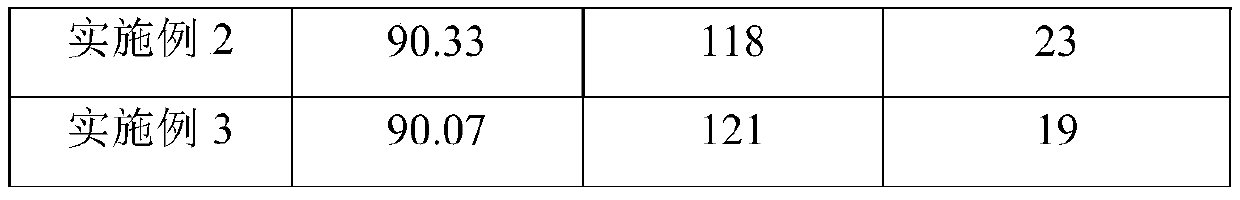

Examples

Embodiment 1

[0022] A kind of water-repellent rainproof coating for glass, comprises primer coating and top coating, comprises the following steps:

[0023] Step 1, preparation of mixed solvent

[0024] Water and ethanol are mixed according to a weight ratio of 1:50 to obtain a mixed solvent;

[0025] Step 2, prepare primer coating

[0026] Add 3g of allyltrimethylsilane to 100g of the mixed solvent prepared in step 1, add 0.01g of low molecular weight organic acid acetic acid with a mass fraction of 10% as a catalyst, add low-concentration ammonia water, adjust pH=4, and hydrolyze at 40°C for 4h , to obtain the primer coating;

[0027] Step 3. Prepare the topcoat

[0028] Dissolve 5 g of polysiloxane into 100 g of the mixed solvent prepared in step 1, add 0.001 g of zinc chloride, add 5 g of tetraethoxysilane, and stir at room temperature for 24 hours to obtain the required top coating.

[0029] First apply the primer obtained in step 2 to the glass surface, wipe it evenly with a flan...

Embodiment 2

[0031] Step 1, preparation of mixed solvent

[0032] Water and Virahol are mixed in a weight ratio of 1:1 to obtain a mixed solvent;

[0033] Step 2, prepare primer coating

[0034] Add 7g of allyltrimethylsilane to 100g of the mixed solvent prepared in step 1, add 10g of low molecular weight organic acid acetic acid with a mass fraction of 10% as a catalyst, add low-concentration ammonia water to adjust pH=4, hydrolyze at 40°C for 4h, get primer;

[0035] Step 3. Prepare the topcoat

[0036] Dissolve 10g of polysiloxane into 100g of the mixed solvent prepared in step 1, add 0.1g of Lewis acid catalyst zinc chloride, add 1g of tetraethoxysilane, and stir at room temperature for 24h to obtain the required top coating .

[0037] First apply the primer to the glass surface, wipe it evenly with a velvet cloth, let it stand at room temperature for 0.5h until the solvent is completely evaporated, and obtain a 3um thick primer coating, then apply the top coat to the glass surface...

Embodiment 3

[0040] Step 1, preparation of mixed solvent

[0041] Water and isopropanol are mixed according to a weight ratio of 1:20 to obtain a mixed solvent;

[0042] Step 2, prepare primer coating

[0043] Add 5g of 3-(2,3-glycidoxy)propyltrimethoxysilane to 100g of the mixed solvent prepared in step 1, add 1g of 10% by mass fraction of low-molecular-weight organic acid acetic acid as a catalyst, add low-concentration Adjust pH=4 with ammonia water, hydrolyze for 4 hours at 40°C to obtain primer;

[0044] Step 3. Prepare the topcoat

[0045] Dissolve 6g of polysiloxane into 100g of the mixed solvent prepared in step 1, add 0.05g of Lewis acid catalyst zinc chloride, add 2g of tetraethoxysilane, and stir at room temperature for 24h to obtain the desired top coating .

[0046] First apply the primer to the glass surface, wipe it evenly with a velvet cloth, let it stand at room temperature for 0.5h until the solvent is completely evaporated, and obtain a 3um thick primer coating, then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com