Odor removing device for animal fat processing

A technology for removing odor and animal fat, which is applied in the direction of fat oil/fat refining, mixer with rotary stirring device, and fat generation. Reasonable design, improve the effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

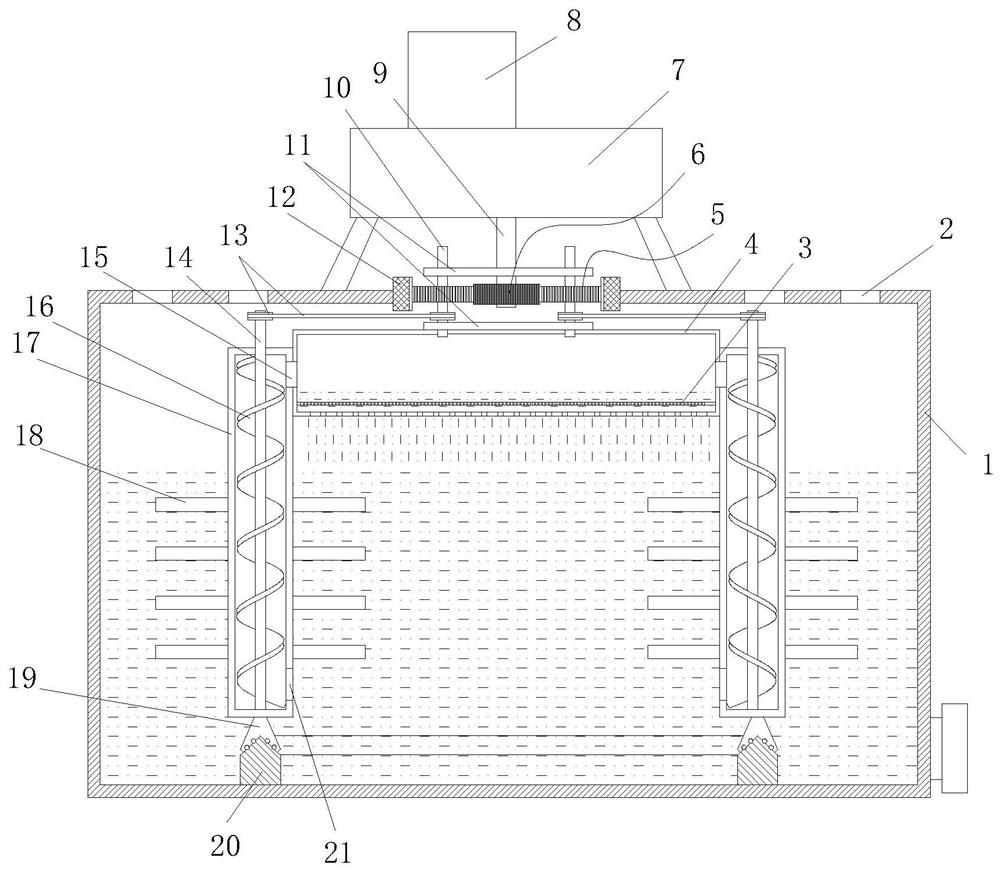

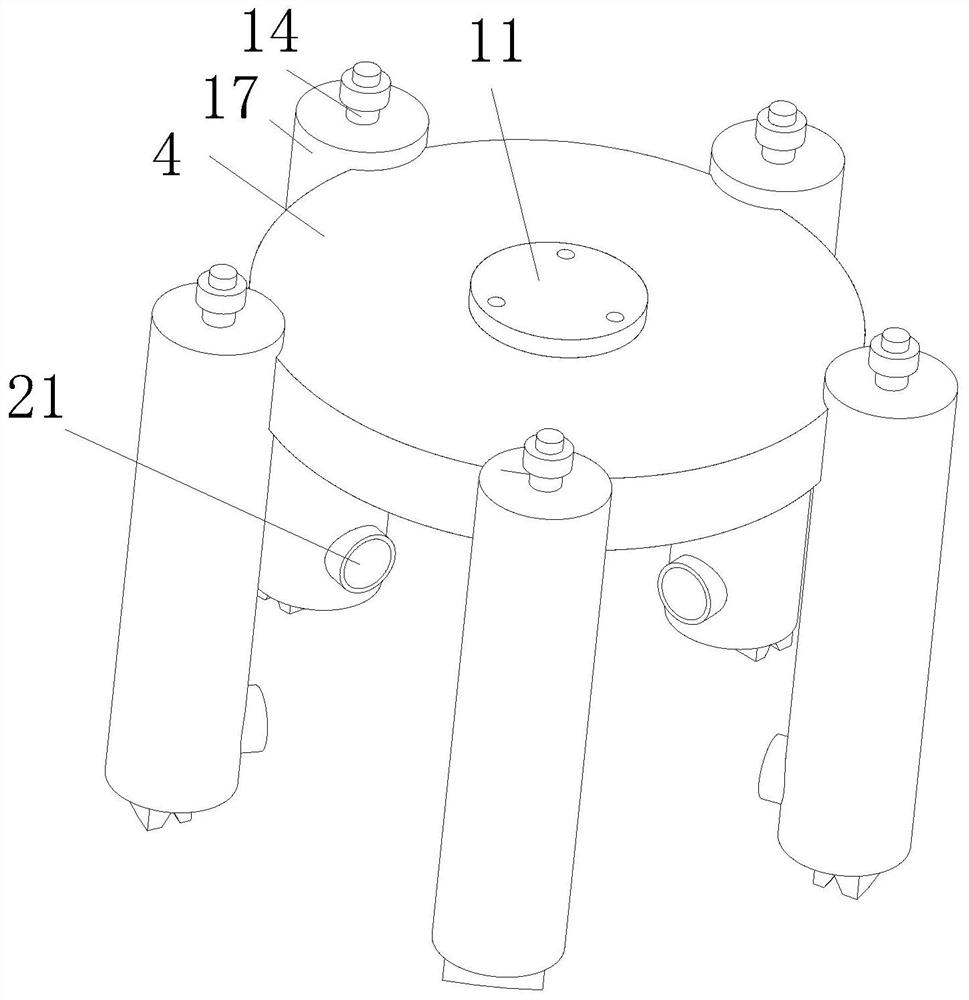

[0021] As a specific embodiment of the power rotating mechanism: the power rotating mechanism includes a gearbox 7 fixed on the outer box 1, the sun gear 6 is coaxially fixed with the sun gear main shaft 9, and the power input end of the gearbox 7 is connected with The rotary motor 8 and the power output end of the gearbox 7 are coaxially fixed with the sun gear main shaft 9 .

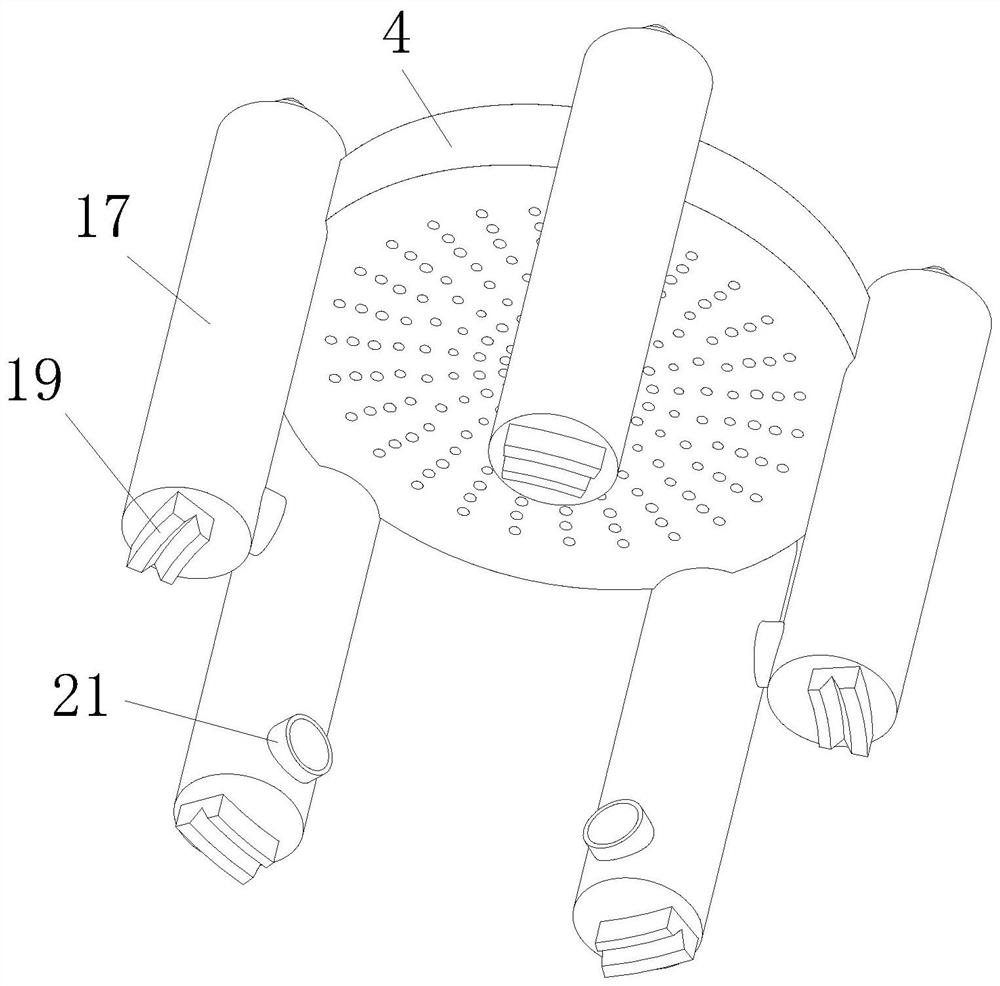

[0022] A horizontal filter screen 3 is set inside the inner box body 4, and the grease is lifted to the inside of the inner box body 4 through the spiral plate 16, and then filtered by the filter screen 3 and sprinkled into the outer box body 1 from the leakage hole, so that the device While removing the peculiar smell, it can realize the filtration of grease and remove the impurities inside the grease. This device lifts the grease to the inside of the inner box 4 through the screw lifting mechanism, and the screw lifter can squeeze the grease inside the inner box 4 to a certain extent. The effect is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com