A post-processing method and application of double perovskite crystals

A double perovskite and crystal technology, which is applied in the field of post-processing of double perovskite crystals, can solve the problems of low carrier mobility, carrier lifetime product product, large leakage current, and limitation of preparation methods, and achieve Effects of improving mobility and defect density, improving performance, and reducing defect density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Cs in this example 2 AgBr 6 The post-processing method of the crystal specifically includes the following steps:

[0030] (1) Use tweezers to remove the Cs grown in the solution 2 AgBr 6 take out;

[0031] (2) Cs to be taken out 2 AgBr 6 Place in an oven at 100°C, and anneal in air for 30 minutes;

[0032] (3) Take out the crystal in step (2) from the oven, and place it in the air to cool for 5 minutes;

[0033] (4) prepare a sufficient amount of isopropanol solution that can completely immerse the crystal;

[0034] (5) Soak the crystal in step (3) in the isopropanol solution prepared in step (4) for 10 min;

[0035] (6) Place the crystal in step (5) in the air to dry naturally, that is, complete the post-processing of the crystal, and take out the crystal for performance testing;

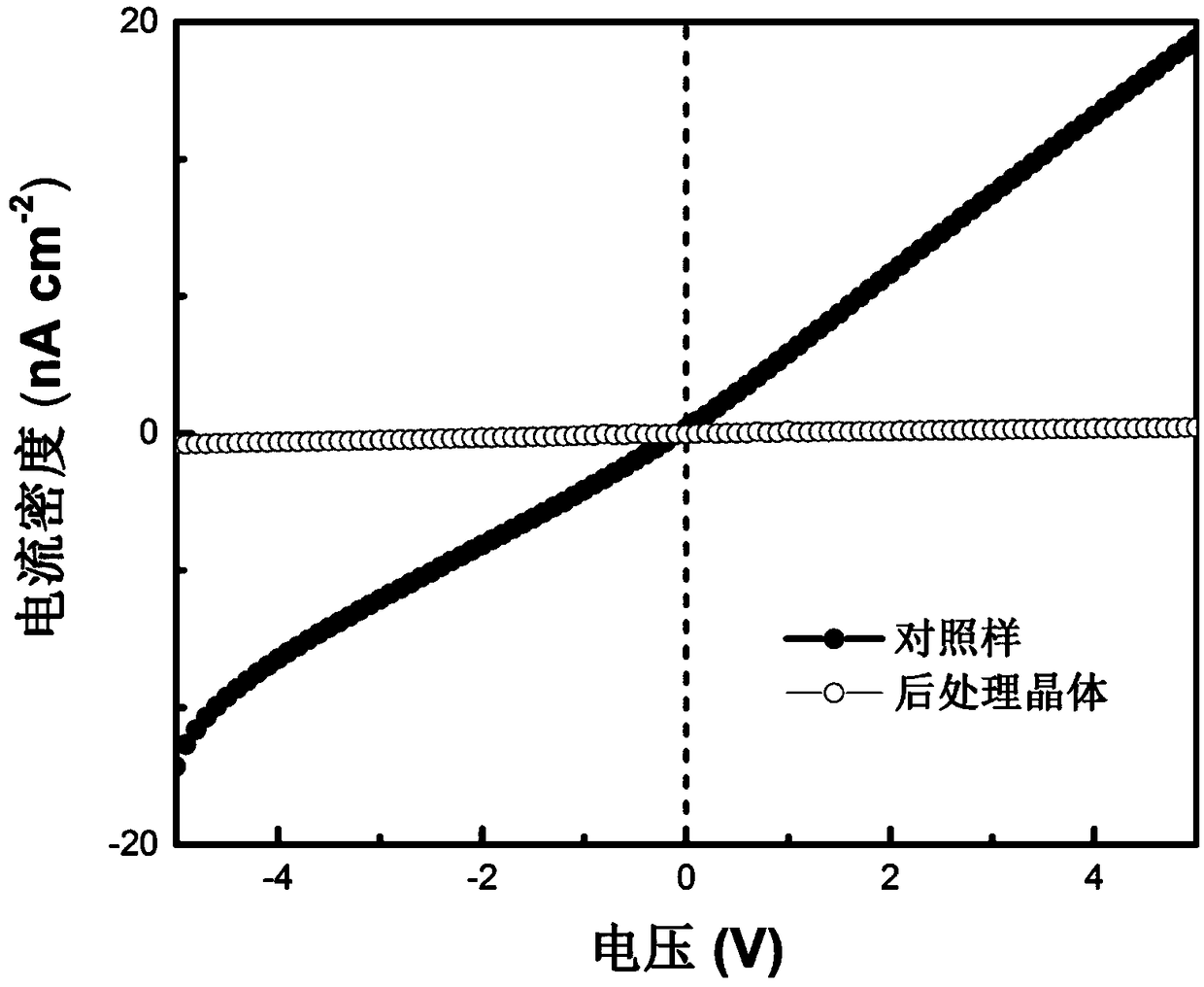

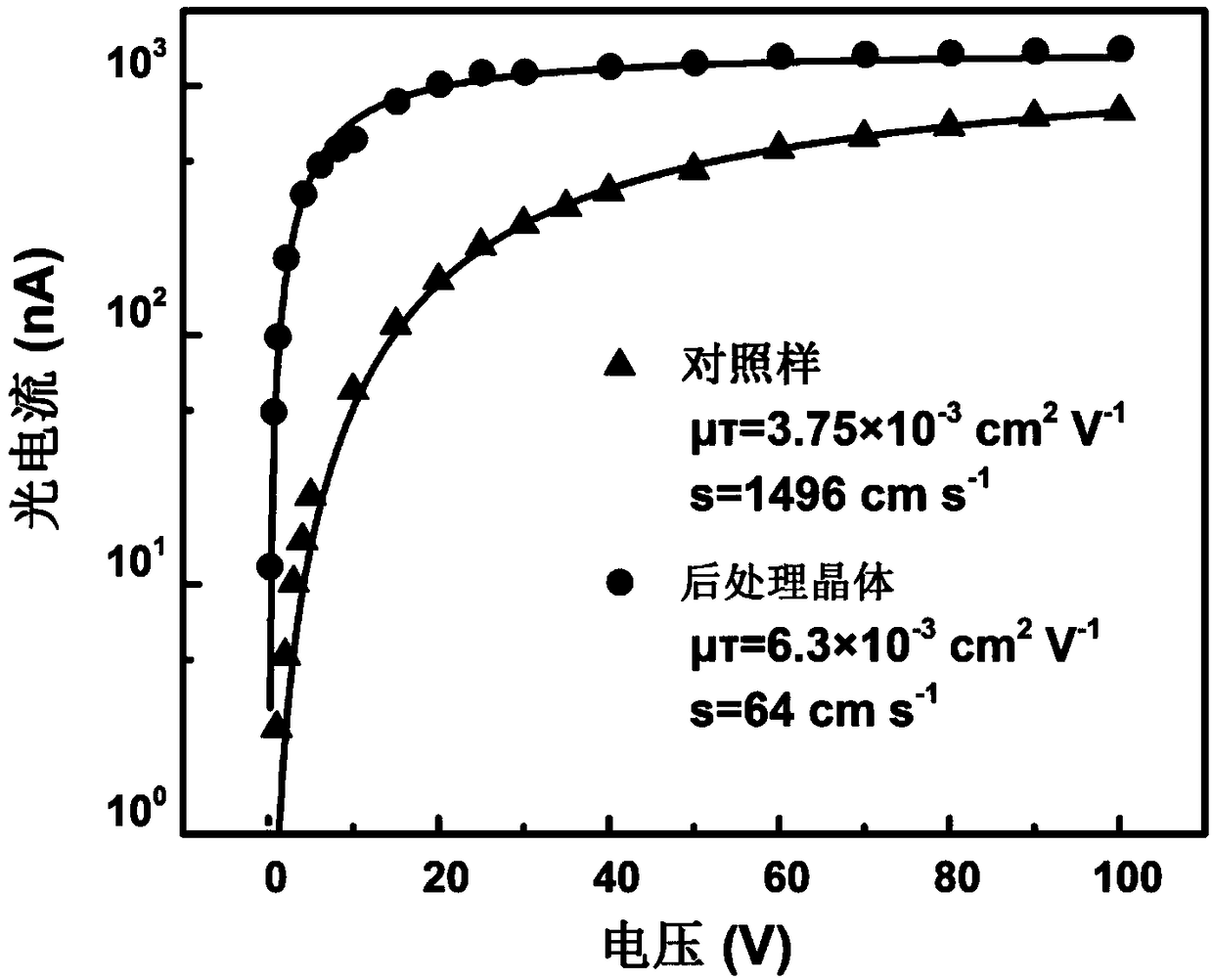

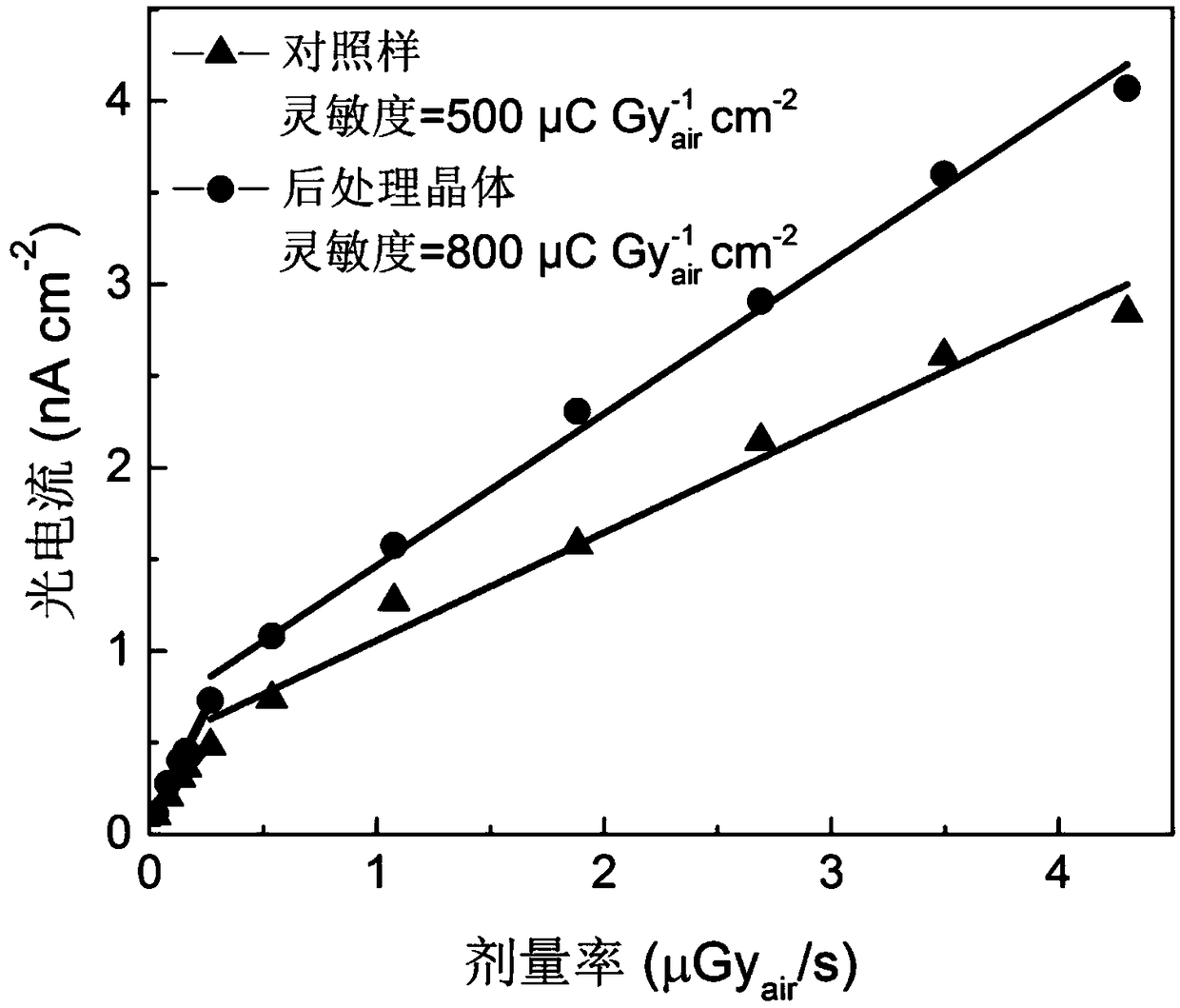

[0036] (7) Get post-treated crystals and no post-treated crystals, i.e. the control sample, vapor-deposit 40nm thick gold electrodes on its upper and lower surfaces, and perform a per...

Embodiment 2

[0041] (1) Use tweezers to remove the Cs grown in the solution 2 AgBr 6 take out;

[0042] (2) Cs to be taken out 2 AgBr 6 Placed in an oven at 200°C, and annealed in air for 120 minutes;

[0043] (3) The crystal in step (2) is taken out from the oven, and placed in the air to cool for 15 minutes;

[0044] (4) prepare a sufficient amount of ethanol solution that can completely immerse the crystal;

[0045] (5) Soak the crystal in step (3) in the ethanol solution prepared in step (4) for 15 minutes;

[0046] (6) Place the crystal in step (5) in the air to dry naturally, that is, complete the post-processing of the crystal, and take out the crystal for performance testing;

[0047] (7) Get post-treated crystals and no post-treated crystals, i.e. the control sample, vapor-deposit 40nm thick gold electrodes on its upper and lower surfaces, and perform a performance test;

[0048] (8) Use a semiconductor analyzer to carry out I-V tests on the above-mentioned post-treatment c...

Embodiment 3

[0052] (1) Use tweezers to remove the Cs grown in the solution 2 AgBiCl 6 take out;

[0053] (2) Cs to be taken out 2 AgBiCl 6 Place in an oven at 150°C, and anneal in air for 90 minutes;

[0054] (3) Take out the crystal in step (2) from the oven, and place it in the air to cool for 10 minutes;

[0055] (4) prepare a sufficient amount of acetone solution that can completely immerse the crystal;

[0056] (5) Soak the crystal in step (3) in the acetone solution prepared in step (4) for 10 min;

[0057] (6) Place the crystal in step (5) in the air to dry naturally, that is, complete the post-processing of the crystal, and take out the crystal for performance testing;

[0058] (7) Get post-treated crystals and no post-treated crystals, i.e. the control sample, vapor-deposit 40nm thick gold electrodes on its upper and lower surfaces, and perform a performance test;

[0059] (8) Use a semiconductor analyzer to carry out I-V tests on the above-mentioned post-treatment crystal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com