High-vacuum metal powder valve

A metal powder and high-vacuum technology, which is applied in the direction of valve lift, valve details, valve device, etc., can solve the problems that the valve body cannot effectively control the amount of powder, and the valve body seal cannot meet the process requirements, so as to reduce erosion and improve Effects of service life, safety and service life improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

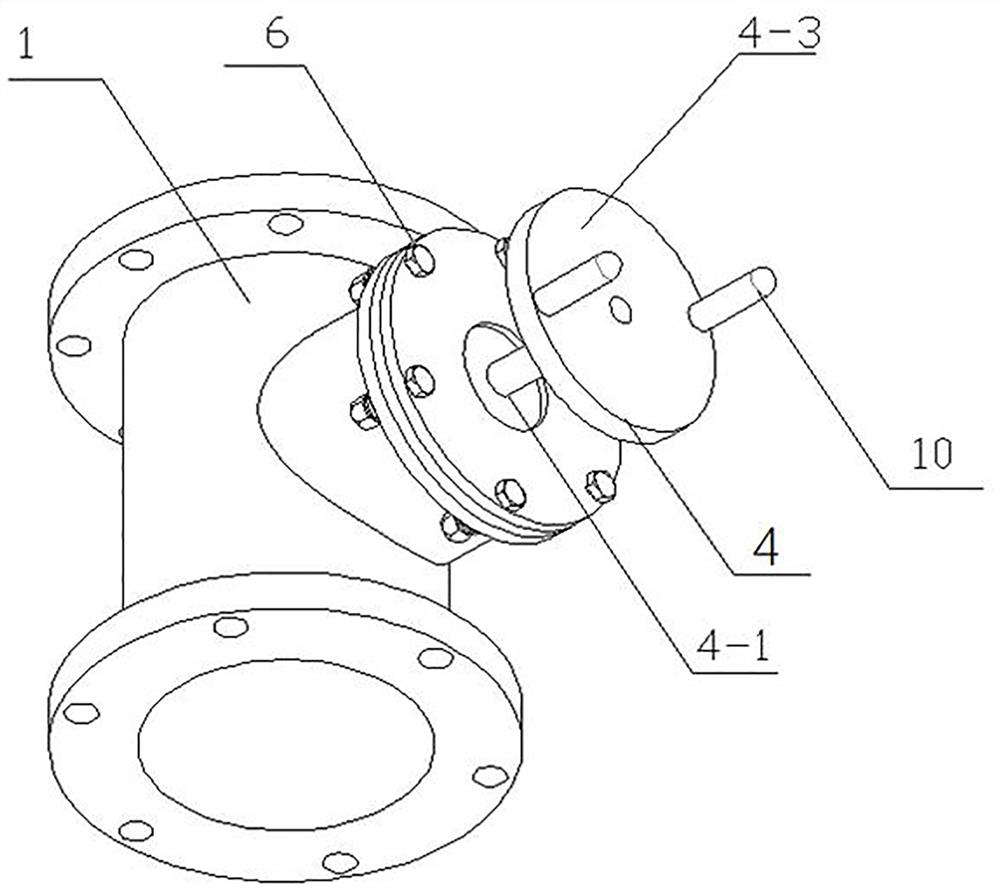

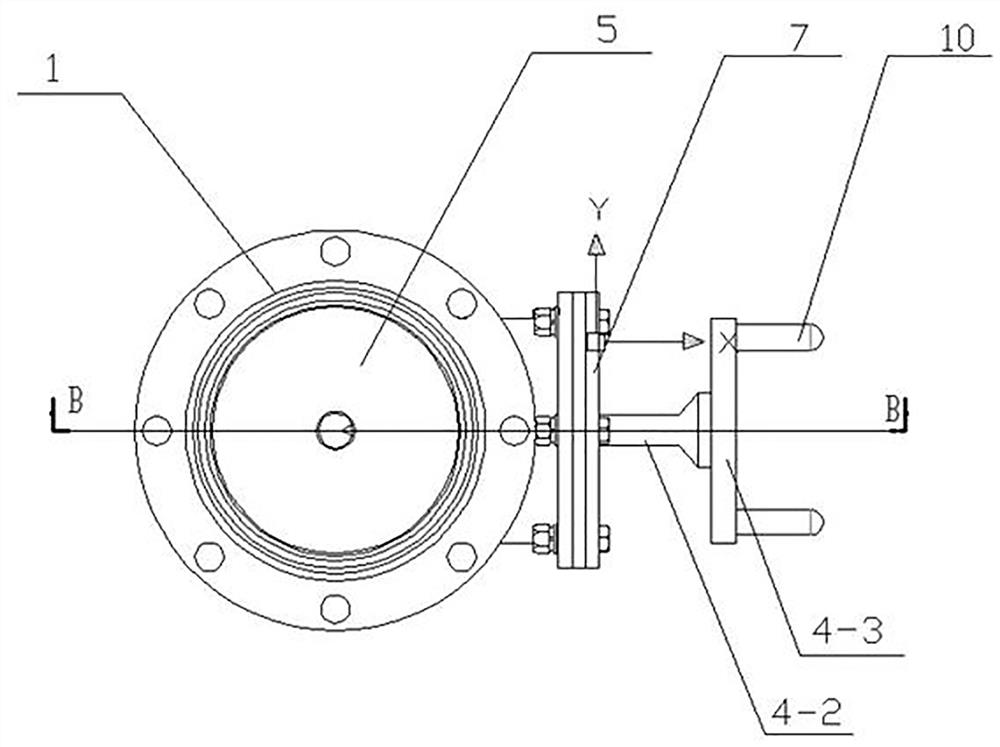

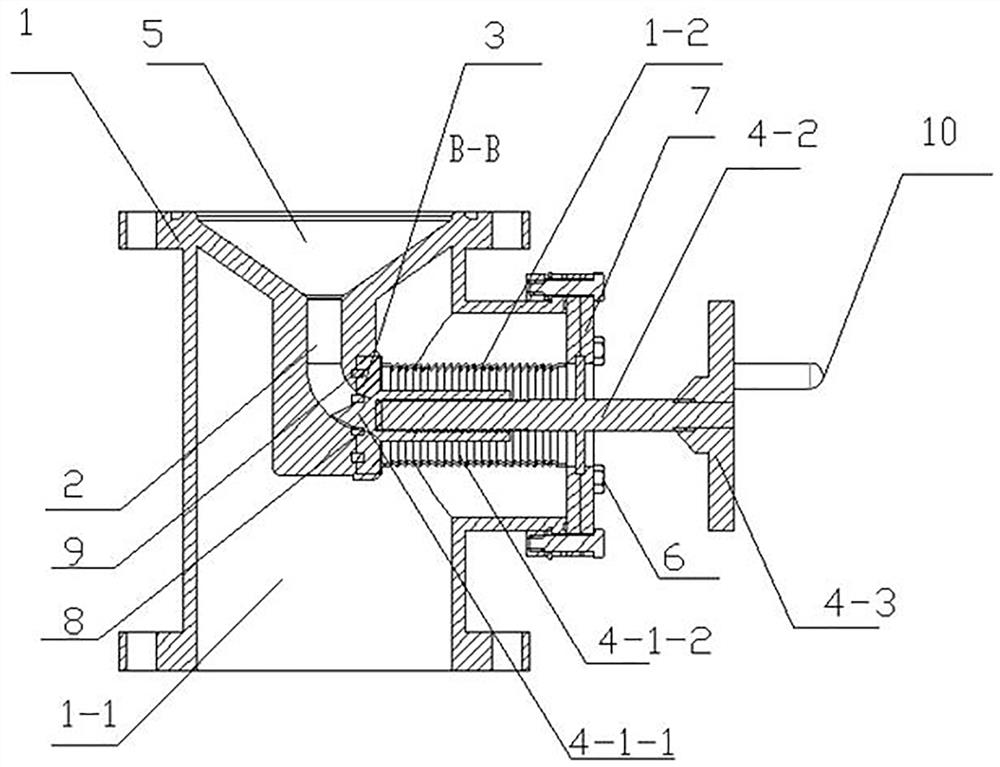

[0033] Such as Figure 1-3 As shown, a high-vacuum metal powder valve includes a valve body 1, an elbow 2, an abutment 3 and a valve core part 4, and a fluid channel 1-1 and a valve communicating with the fluid channel 1-1 are arranged in the valve body 1. The hollow cavity 1-2, the elbow 2 is installed in the fluid channel 1-1, the abutting piece 3 is connected with the end of the elbow 2 away from the inlet of the fluid channel 1-1, the valve core part 4 extends into the hollow cavity 1-2 and Contact with the abutment 3;

[0034] The spool part 4 includes a moving assembly 4-1, a valve stem 4-2 and a hand wheel 4-3. One end of the moving assembly 4-1 is adapted to the abutment 3, and one end of the valve stem 4-2 is connected to the moving assembly 4. -1 is threaded and its other end is connected with the handwheel 4-3, and the end of the valve stem 4-2 away from the thimble 4-1-1 is connected with the handwheel 4-3 through a quick-connect pin.

[0035] The valve stem 4-2 ...

Embodiment 2

[0045]Except the technical feature identical with embodiment 1, also comprise following difference:

[0046] When the valve stem 4-2 is located at 10mm, that is, the thimble 4-1-1 moves out of the center hole of the contact piece 3, the thimble 4-1-1 no longer blocks the elbow 2, and plays the role of opening the valve body, and the metal powder Outflow at maximum flow from fluid channel 1-1.

[0047] The invention works as follows:

[0048] The valve stem 4-2 is rotated by operating the handwheel 4-3 transmission device, and at the same time, the valve stem 4-2 drives the valve core part 4 through thread transmission to realize the opening and closing of the valve. -1-1 cooperate with each other, and the rotation of the handwheel 4-3 drives the valve stem 4-2 to move back and forth to control the flow of powder. The movement distance is 0~10mm. When the valve stem 4-2 reaches the position of 10mm, the valve It is in the fully open position in the pipeline. At this time, onl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com