Planimeter detection method

A detection method and technology of a plotter, which are applied in the field of plotter detection, can solve problems such as the inability to accurately reflect the detection accuracy of the plotter, and achieve the effects of high shape stability, high reliability, and not easy to absorb water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

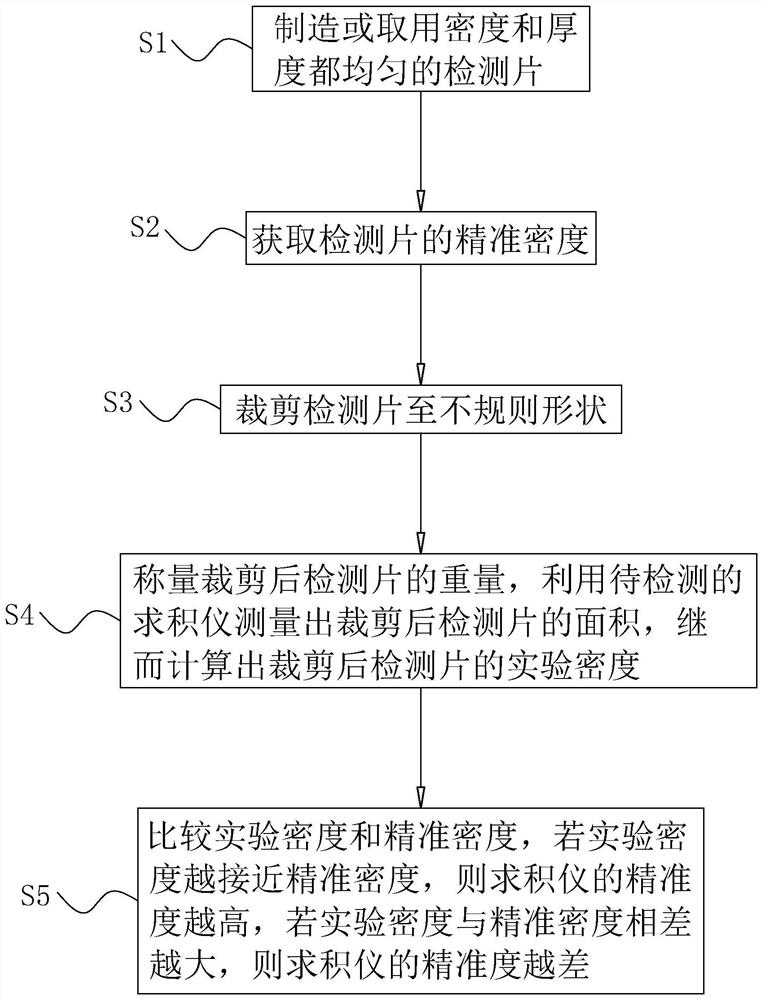

[0044] refer to figure 1 , a kind of planimeter detection method, comprises the steps:

[0045] S1. Take a test piece with uniform density and thickness. The thickness of the test piece is d. Ultrasonic density testing is performed on the test piece for ultrasonic declaration to ensure that the test piece has a uniform density and no bubbles, cracks or wormholes. In the embodiment, the paper with a thickness of 1 mm is used, and the paper with a certain thickness can effectively reduce the requirements for subsequent measuring instruments;

[0046] S2, obtain the precise density ρ of the test piece 1 ; The precise density ρ of the test piece 1 It can be obtained directly through the paper acquisition method. If you are worried about the precise density ρ obtained directly 1 is not accurate enough, the following scheme can also be used to obtain the actual precise density ρ 1 , including the following steps;

[0047] S21, using scissors to cut or punch the test piece to a ...

Embodiment 2

[0055] A kind of planimeter detection method, the difference with embodiment one is that the detection sheet adopts the metal sheet that thickness is 2mm, such as stainless steel sheet or pure copper, the density uniformity of pure copper is higher, the mode of cutting detection sheet is uniform. Using wire cutting.

[0056] Compared with Example 1, the paper has a certain degree of water absorption, while the weight and properties of the metal sheet are relatively stable, and the experimental accuracy is better. In addition, in the process of using the planimeter for detection, because the shape of the metal sheet is relatively stable, the planimeter In the process of detecting the edge of the irregular shape, the collection accuracy of the irregular shape is higher, because the paper is easy to roll and bend, in order to cooperate with the use of the metal sheet, the wire cutting is used to ensure the cutting accuracy of the metal sheet.

Embodiment 3

[0058] refer to figure 2 , a kind of planimeter detection method, comprises the steps:

[0059] S1, manufacturing or taking test sheets with uniform density and thickness;

[0060] S2, cutting the detection piece to a regular shape, and obtaining the quality D of the regular shape detection piece 1 , Calculate the area S of the regular shape detection piece 1 , through D 1 / S 1 Calculate the base ratio i 1 ;

[0061] S3, cutting the detection piece to an irregular shape;

[0062] S4, weighing the weight D of the detection piece after cutting 2 , use the planer to be tested to measure the area S of the cut test piece 2 , through D 2 / S 2 Calculate the experimental ratio i 2 ;

[0063] S5, comparison base ratio i 1 and the experimental ratio i 2 , if the experimental ratio i 2 The closer to the benchmark ratio i 1 , the precision of the integrator is higher, if the experimental ratio i 2 Ratio to fine benchmark i 1 The larger the difference, the worse the accu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com