Assembly multi-view change detection method and device based on feature matching

A technology of feature matching and change detection, which is applied in the field of image processing, can solve the problems of failure to realize the type identification of assembly errors and assembly errors, and achieve the effects of shortening the production cycle, high real-time performance, and reducing the failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

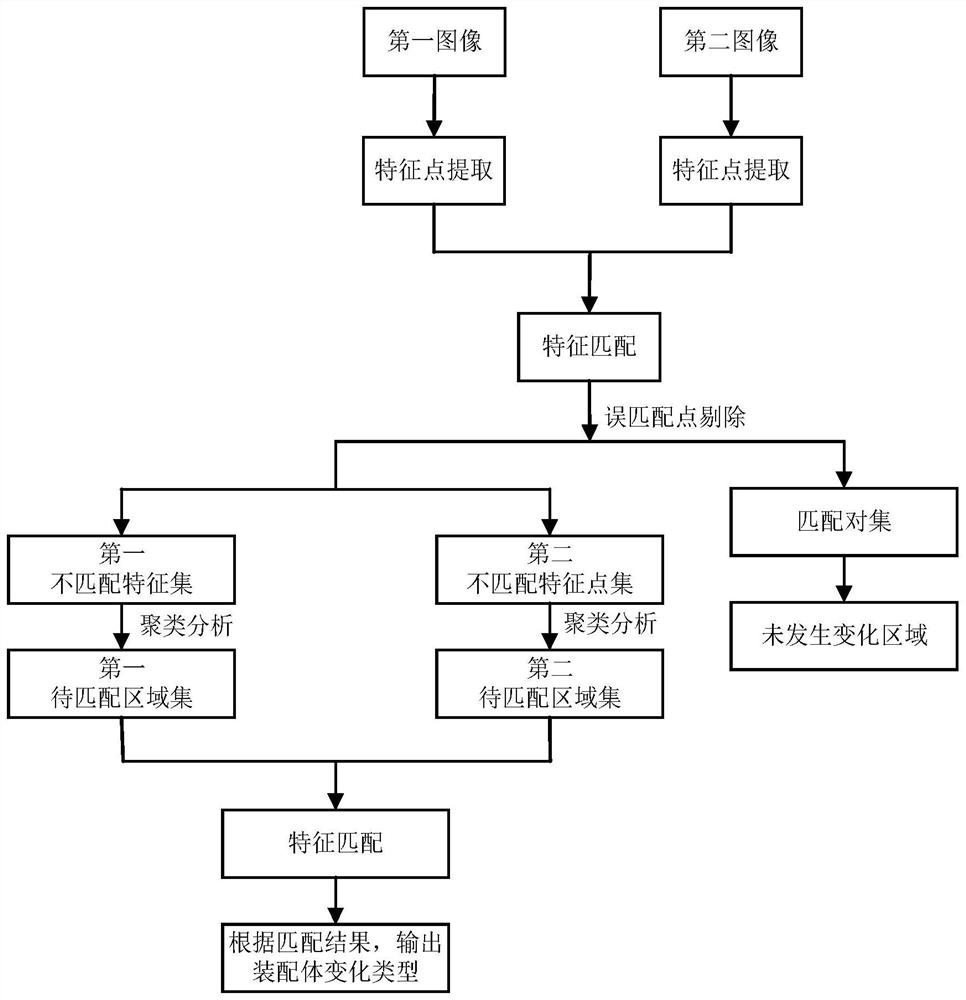

[0058] A feature-matching-based assembly multi-view change detection method, comprising the following steps:

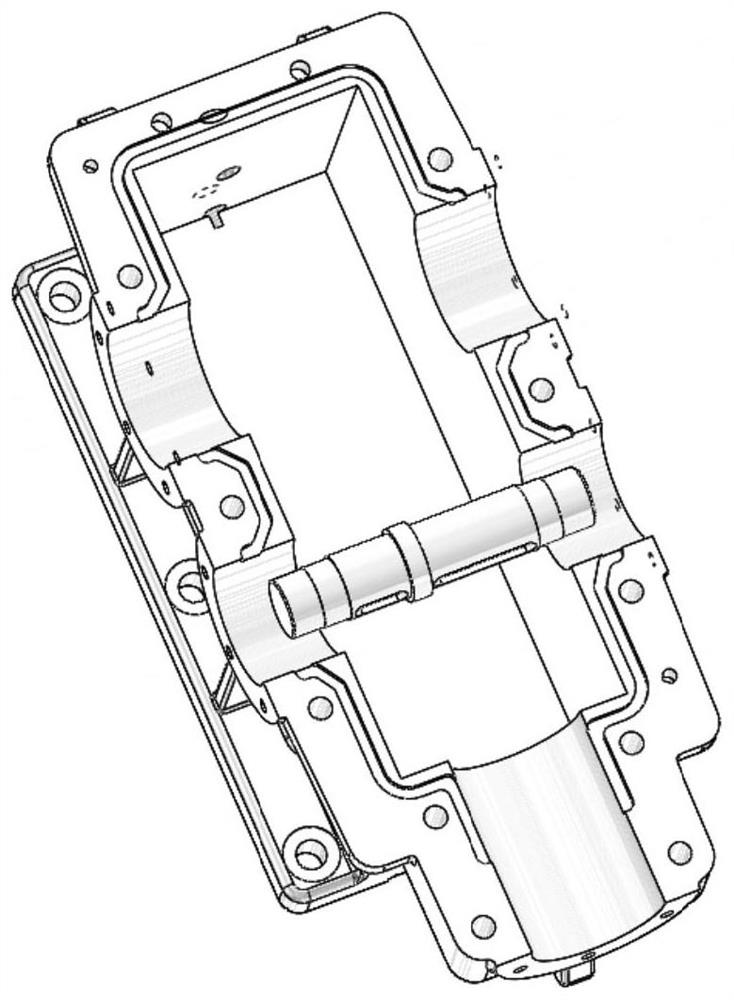

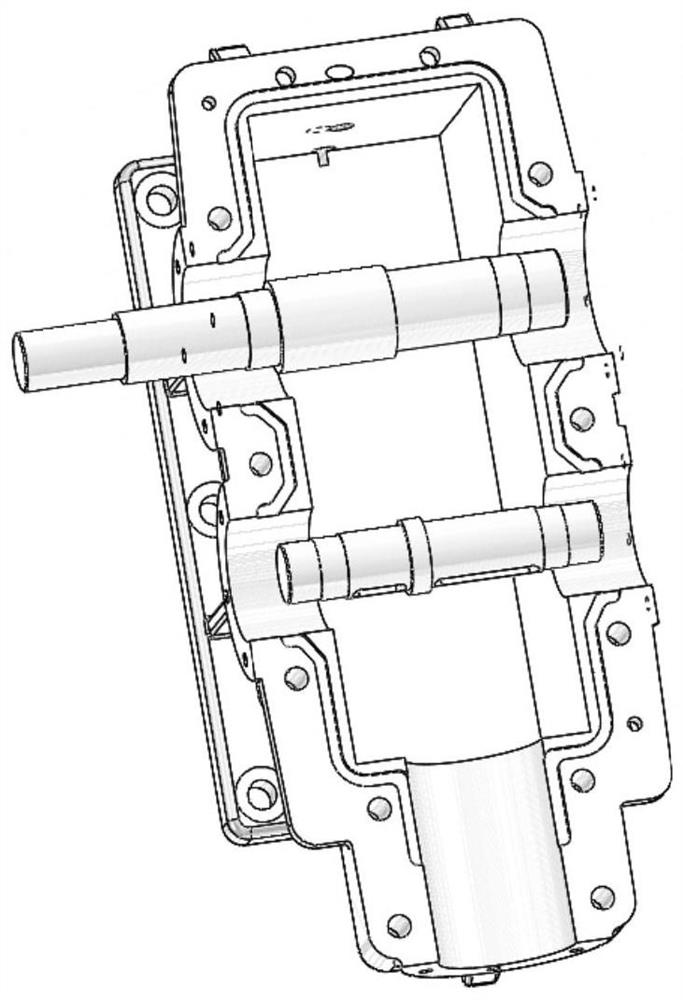

[0059] S1. Acquire a first image and a second image, the first image is an image of the assembly at a previous moment, and the second image is an image at a later moment of the assembly. In this embodiment, the shooting angles of the assembly in the first image and the second image are different (that is, the angles between the camera and the assembly are different).

[0060] S2. Using the SIFT algorithm to perform feature point extraction and feature matching of the first image and the second image (SIFT algorithm, Scale Invariant Feature Transform, scale invariant feature transformation), to obtain the matching pair set and the first mismatch point of the first image set and the second mismatch point set of the second image, the mismatch point is a feature point that does not match another image feature point in the image, specifically:

[0061] S21. Extract featur...

Embodiment 2

[0075] Further, the step S3 is specifically:

[0076] Through the K-means clustering algorithm (K-Means algorithm) or other clustering algorithms, perform cluster analysis on the first mismatch point set, divide similar mismatch points into the same cluster, and obtain several first mismatch points clustering; cluster analysis is performed on the second set of unmatched points, and similar unmatched points are divided into the same cluster to obtain several second unmatched point clusters.

[0077] For example, K mismatch points in the first mismatch point set are randomly selected as centroids, and Euclidean distances from each mismatch point in the first mismatch point set to each centroid are calculated. The smaller the Euclidean distance, the higher the similarity between the mismatch point and the centroid. Sequentially divide each unmatched point into the cluster where the centroid with the smallest Euclidean distance is located, and update the centroid of the cluster w...

Embodiment 3

[0086] Assume that in step S3, a first region set to be matched including M first regions to be matched and a second region set to be matched including N second regions to be matched are obtained.

[0087] see Figure 10 , the step S4 is specifically:

[0088] S41. Select region k in the second region to be matched; perform feature matching on region k and n first regions to be matched respectively, and calculate matching degree P:

[0089]

[0090] Among them, T represents the number of matching pairs between the first region to be matched and the second region to be matched, A represents the number of feature points in the first region to be matched, and B represents the number of feature points in the second region to be matched. The larger the value of P, the greater the number of matching pairs between the first region to be matched and the second region to be matched, and the higher the similarity.

[0091] If the maximum value P among the several matching degrees ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com