Preparation device and method of waste gas purifier box shell

A technology of exhaust gas purifier and preparation device, which is applied in the field of sheet metal forming, can solve the problems of low production efficiency, backward technology and high cost, and achieve the effects of improving production rhythm, reducing labor intensity and high degree of automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0090] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

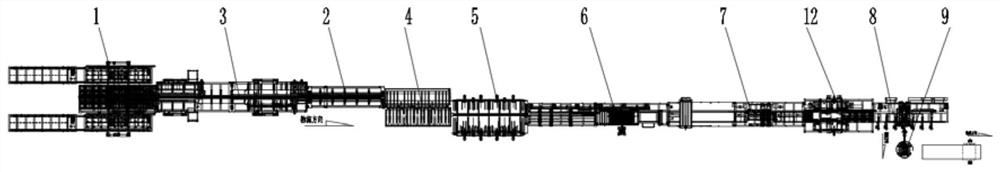

[0091] Please refer to figure 1 , the present embodiment provides a preparation device for an exhaust gas purifier casing, including:

[0092] Suction cup feeder 1, the suction cup feeder 1 is used to feed the material boards on the stack for preparing the box shell;

[0093] A plurality of conveying components 2 are used to convey the material sheets on the preparation device;

[0094] The step-by-step punching machine 3 is used to punch out several groups of symmetrical connection holes, three groups of symmetrical V-shaped bending part cuts and two The group is located on the hypotenuse at both ends of the sheet, and the cut of the V-shaped bending part co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com