Permanent magnetic direct-drive gantry crane

A direct-drive door seat and crane technology, applied in electromechanical devices, mechanical equipment, non-variable pumps, etc., can solve the problem of high design load-bearing capacity requirements for installation and support parts, cumbersome and complicated maintenance and repair work, and space requirements for machine rooms Higher problems, to avoid high temperature loss of magnetism, reduce failure rate and maintenance costs, avoid frequent commutation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

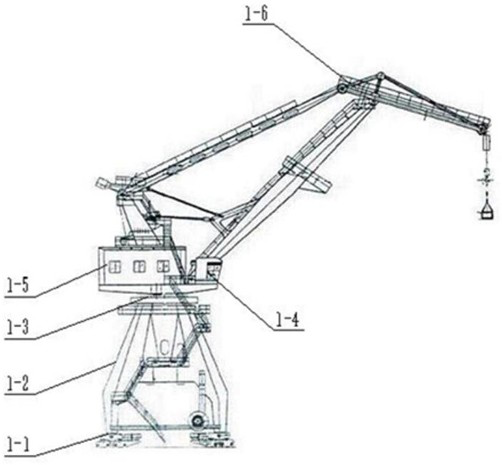

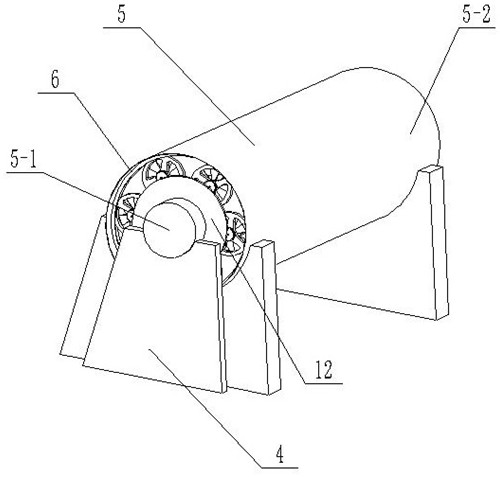

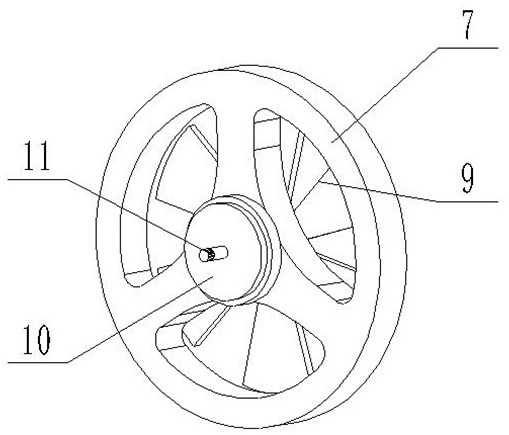

[0021] like Figure 1-4 The permanent magnet direct drive portal crane shown includes a portal frame 1-2, a traveling mechanism 1-1 is provided at the lower part of the portal frame, a slewing platform 1-3 is arranged at the upper part of the portal frame, and a cab is set on the slewing platform 1-4. Machine room 1-5 and boom system 1-6; human-computer interaction system is installed in the driver's room; two motor brackets are installed in the machine room, and two permanent magnet direct drive motors are respectively installed for supporting mechanism and opening closing mechanism; the stator shaft 5-1 of the permanent magnet direct drive motor is fixed on the motor bracket, the permanent magnet reel 5-2 is set outside the stator shaft, and is installed on the motor bracket through the bearing seat; the end of the permanent magnet reel An encoder is set at the top, and the signal of the encoder is connected to the PLC control circuit; a steel rope is set on the permanent ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com