Preparation method of medium-temperature co-fired atomizing core and prepared medium-temperature co-fired atomizing core

An atomizing core and co-firing technology, used in ceramic products, pharmaceutical equipment, tobacco, etc., can solve the problems of poor adhesion between thick-film electrodes and ceramic surfaces, poor printability of paste, and low yield rate, etc. Sintering shrinkage, not easy to fall off, strong electronic conductivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

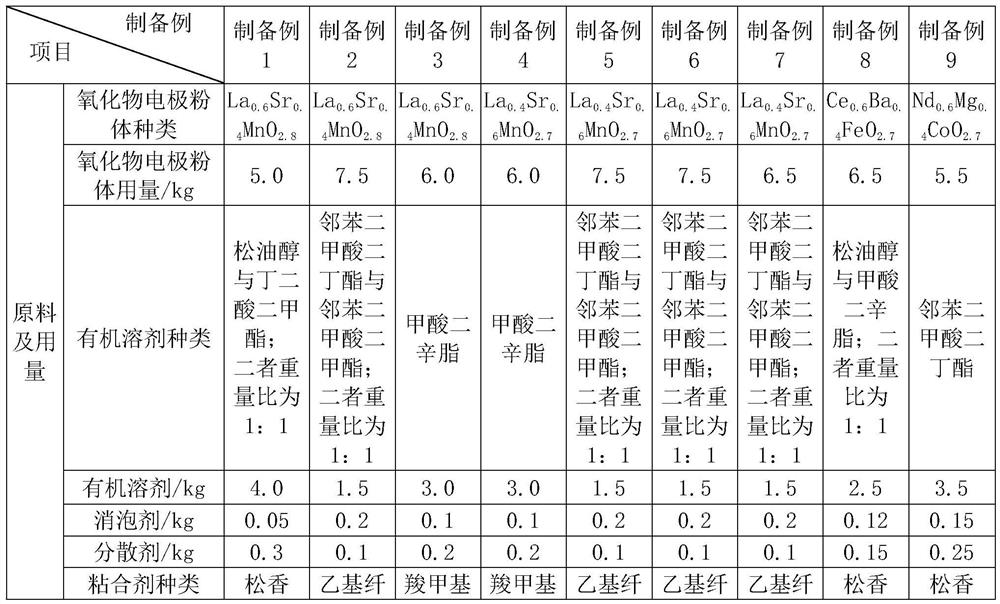

preparation example Construction

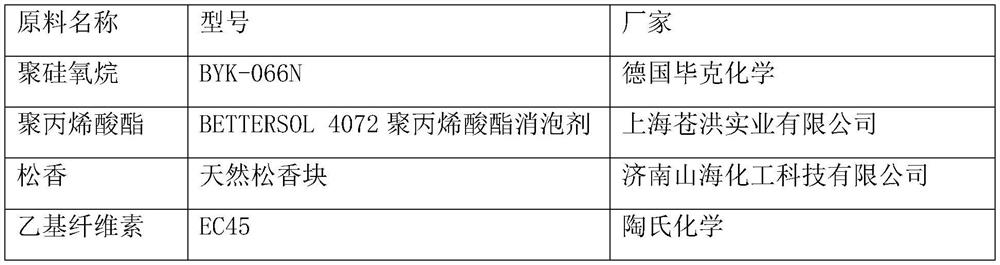

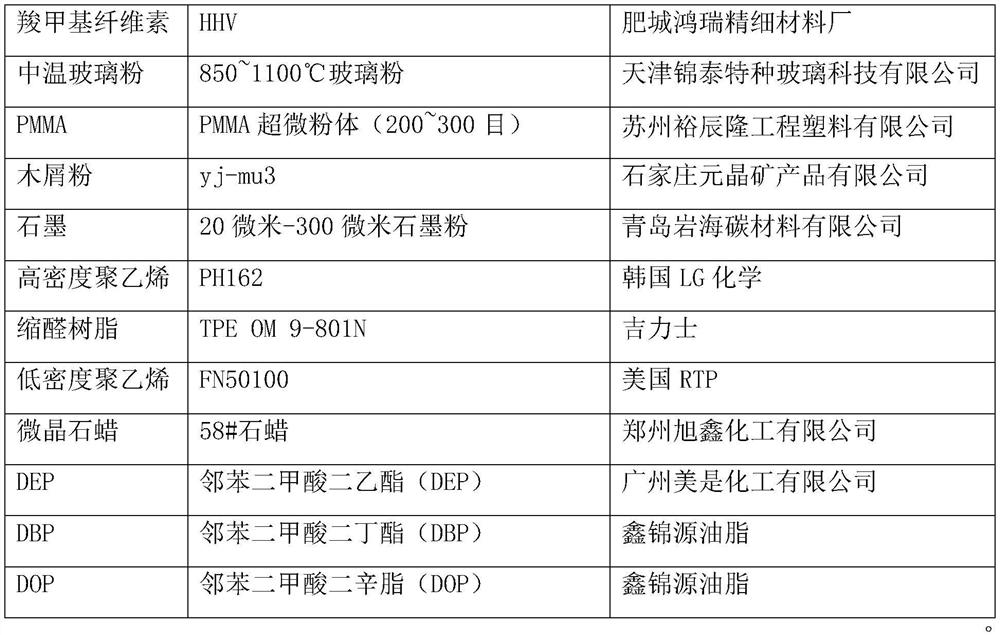

[0125] Examples of Preparation of Raw Materials and / or Intermediates

[0126] In the following preparations:

preparation example 1

[0130] A kind of oxide printing paste, the oxide electrode powder used in the oxide printing paste of this preparation example, its chemical formula is: La 1-x Sr x MnO 3-δ . Wherein, x=0.4; δ=0.2.

[0131] The preparation process is:

[0132] According to the stoichiometric ratio, 0.6 mol of La(NO 3 ) 3 , 0.4mol of Sr(NO 3 ) 3 , 1mol of Mn(NO 3 ) 3 Dissolve in 20mol (260ml) water, add 0.5mol of citric acid, add 0.1mol of polyacrylic acid surfactant, place the above solution in a constant temperature water bath at 80°C, and adjust the pH value by dropping a 25% ammonia solution , keep the pH value at 6, continue to heat and stir in the water bath, the stirring speed is 120rpm, until the solution is evaporated to dryness, and the oxide electrode precursor is obtained, and the precursor is placed in a muffle furnace for calcination. The holding time is 2 hours; after being out of the furnace, it is ground through a 200-mesh sieve to obtain La 0.6 Sr 0.4 MnO 2.8 Powd...

preparation example 4

[0138] An oxide printing paste, the difference from Preparation Example 3 is that the oxide electrode powder used in the oxide printing paste in this preparation example has a chemical formula of: La 1-x Sr x MnO 3-δ . Wherein, x=0.6; δ=0.3.

[0139] The preparation process is:

[0140] According to the stoichiometric ratio, 0.4 mol of La(NO 3 ) 3 , 0.6mol of Sr(NO 3 ) 2 , 1mol of Mn(NO 3 ) 3 Dissolve in 20mol (260ml) water, add 0.5mol of citric acid, add 0.1mol of polyacrylic acid surfactant, place the above solution in a constant temperature water bath at 80°C, and adjust the pH value by dropping a 25% ammonia solution , keep the pH value at 6, continue to heat and stir in the water bath, the stirring speed is 120rpm, until the solution is evaporated to dryness, and the oxide electrode precursor is obtained, and the precursor is placed in a muffle furnace for calcination. The holding time is 3h; after being out of the furnace, it is ground through a 200-mesh sieve ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com