Potassium polyphosphate slow-dissolving compound fertilizer and its preparation method and application

A technology of potassium polyphosphate and compound fertilizer, applied in ammonium orthophosphate fertilizer, alkaline orthophosphate fertilizer, application and other directions, can solve the problems of increasing the cost of transportation and packaging, prone to agglomeration, etc. Agglomeration, high fertilizer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

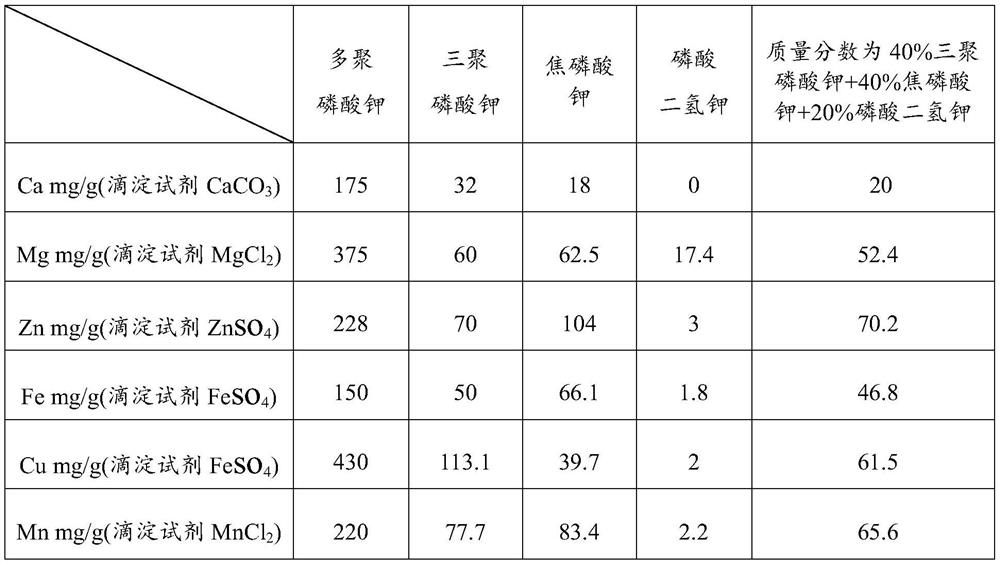

Image

Examples

Embodiment 1

[0076] The preparation method of the potassium polyphosphate slow-dissolving compound fertilizer provided by the present embodiment may further comprise the steps:

[0077] (1) Put 61.22g of potassium hydroxide with a content of 98.5% in a 500ml beaker, add water to make a solution with a mass fraction of 55%, take 80.75g of phosphoric acid with a mass fraction of 85.1%, and slowly dissolve the phosphoric acid while stirring. Pour into a beaker containing potassium hydroxide solution, and mix well to obtain a clear neutralization solution;

[0078] (2) Add the neutralization solution obtained in step (1) into a ceramic evaporating dish, then place it in a muffle furnace, heat up, and heat at a constant temperature of 800°C for 4 hours, dehydration and polymerization, to obtain a high-temperature melt, and lose weight on ignition 0.1%;

[0079] (3) Carefully take out the ceramic evaporating dish that is equipped with high-temperature melt with pliers, and pour it on a clean st...

Embodiment 2

[0085] The preparation method of the potassium polyphosphate slow-dissolving compound fertilizer provided by the present embodiment may further comprise the steps:

[0086] The preparation method is basically the same as that of Example 1, the only difference being that the potassium hydroxide potassium source is replaced by potassium carbonate K 2 CO 3 , and change its dosage. Concretely, step (1) comprises: adding water to 77.26g content of 95.0% potassium carbonate to make a 55% solution is placed in a 500ml beaker, taking 80.75g concentration of 85.1% phosphoric acid, slowly pouring it into the beaker while stirring, mixing After uniformity, a clear neutralization solution is obtained. All the other steps (2), (3), (4) and (5) are the same as in Example 1.

[0087] The same method as in Example 1 was used for detection, and it was found that basically the same results could be achieved.

Embodiment 3

[0089] The preparation method of the potassium polyphosphate slow-dissolving compound fertilizer provided by the present embodiment may further comprise the steps:

[0090] (1) getting 0.8046kg mass fraction is 85.15% food grade phosphoric acid and 0.6091kg mass fraction is 98.5% food grade potassium hydroxide, potassium hydroxide is dissolved in water and made mass fraction is 55% solution, while stirring Slowly add potassium hydroxide solution into phosphoric acid to carry out neutralization reaction to obtain a clear neutralization solution;

[0091] (2) Add the neutralizing solution into a fixed cellar-type polymerization furnace, heat and dehydrate and polymerize at 850° C. to obtain a high-temperature melt with a weight loss on ignition of 0.1%;

[0092] (3) After the high-temperature melt is kept at 800±25° C. for a certain period of time, the weight loss on ignition of sampling analysis is: 0.2%, and at 850±25° C., adjust the heating heat and the amount of neutralizing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com