Preparation method of apple vinegar and product prepared by same

A technology of apple cider vinegar and apple juice, which is applied in the field of food and beverage, and can solve the problem of single flavor of apple cider vinegar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

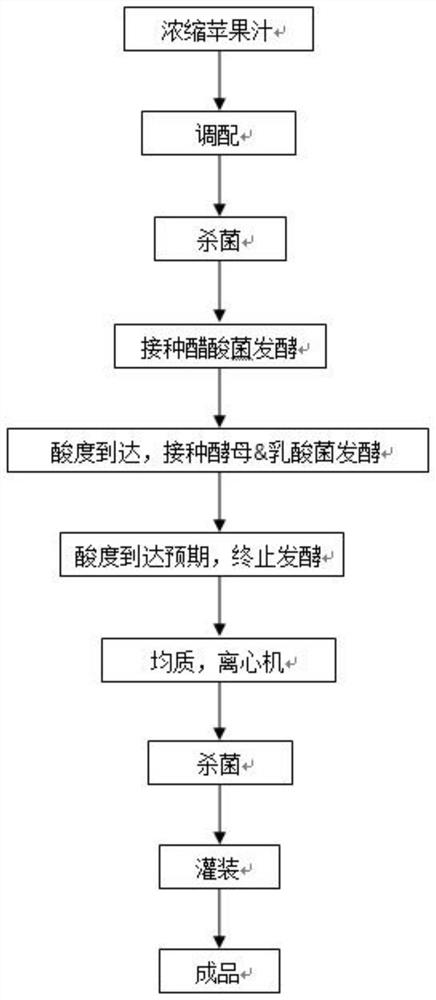

Method used

Image

Examples

Embodiment 1

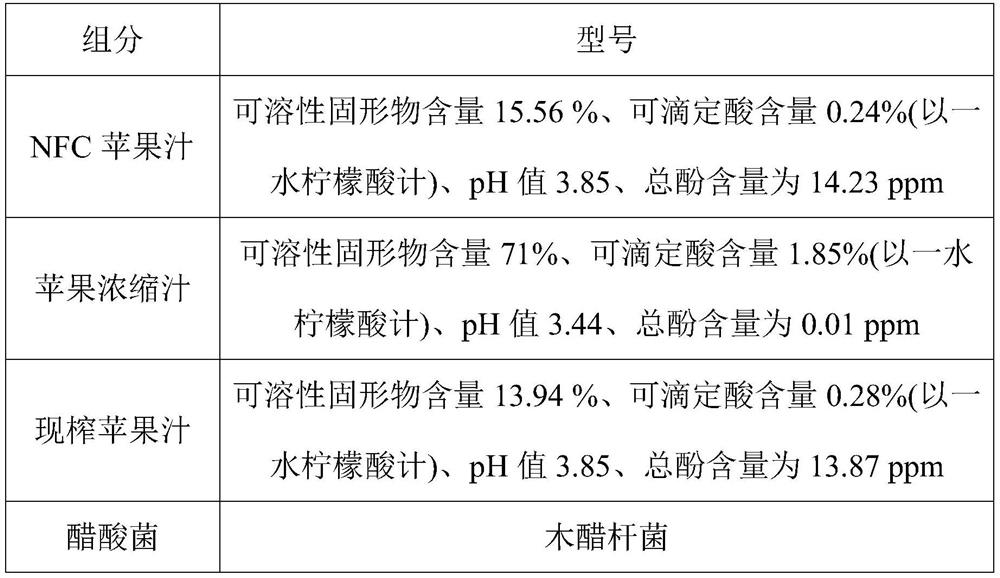

[0057] This embodiment provides an apple cider vinegar. The raw materials for preparing the apple cider vinegar include: 90% of NFC apple juice, 9% of water, 0.5% of acetic acid bacteria, and 0.5% of yeast;

[0058] Described apple cider vinegar is prepared by following preparation method:

[0059] (1) Dilute NFC apple juice with water, filter through a 200-mesh filter, and then sterilize at 105°C for 1 minute to obtain a mixed solution; then inoculate acetic acid bacteria and ferment for 100 hours at 34°C until the acidity of the mixed solution is obtained by one fermentation Centrifuged at 150°T and 4000g centrifugal force, the content of soluble solids is 14%;

[0060] (2) Inoculate the yeast with the mixed solution obtained from step (1) primary fermentation, and then ferment at 32° C. for 24 hours to obtain apple cider vinegar. The acidity of the apple cider vinegar is 170° T, and the content of soluble solids is 12%.

Embodiment 2

[0062] This embodiment provides an apple cider vinegar. The raw materials for preparing the apple cider vinegar include: 20% apple juice concentrate, 50% NFC apple juice, 29% water, 0.35% acetic acid bacteria, 0.35% yeast, Lactic acid bacteria 0.3%;

[0063] Described apple cider vinegar is prepared by following preparation method:

[0064] (1) Mix the concentrated apple juice and NFC apple juice, dilute with water, filter through a 100-mesh filter, and then sterilize at 90°C for 20 minutes to obtain the mixture; then inoculate with acetic acid bacteria and ferment for 80 hours at 34°C until the first fermentation The acidity of the obtained mixed solution is 150 ° T, centrifuged under the condition of centrifugal force 4000g, and the content of soluble solids is 20%;

[0065] (2) Inoculate yeast and lactic acid bacteria with the mixed solution obtained from step (1) primary fermentation, and then ferment at 36° C. for 28 hours to obtain apple cider vinegar. The acidity of th...

Embodiment 3

[0067] This embodiment provides an apple cider vinegar. The raw materials for preparing the apple cider vinegar include: 50% of concentrated apple juice, 10% of freshly squeezed apple juice, 39% of water, 0.35% of acetic acid bacteria, and 0.30% of yeast , lactic acid bacteria 0.35%;

[0068] Described apple cider vinegar is prepared by following preparation method:

[0069] (1) Mix concentrated apple juice and freshly squeezed apple juice, dilute with water, filter through a 300-mesh filter, and then sterilize at 85°C for 30 minutes to obtain a mixed solution; then inoculate acetic acid bacteria and ferment at 33°C for 96 hours until once The acidity of the mixed solution obtained by fermentation is 180 ° T, and the content of soluble solids is 40%;

[0070] (2) Inoculate yeast and lactic acid bacteria with the mixed solution obtained from step (1) primary fermentation, and then ferment at 36° C. for 18 hours to obtain apple cider vinegar. The acidity of the apple cider vine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com