Automatic water retaining panel

A kind of water baffle and automatic baffle technology, applied in dams, flood control panels, water conservancy projects, etc., can solve the problems of high processing cost, low installation efficiency, large panel weight, etc., and achieve reduced processing and installation costs, improved stability, low density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

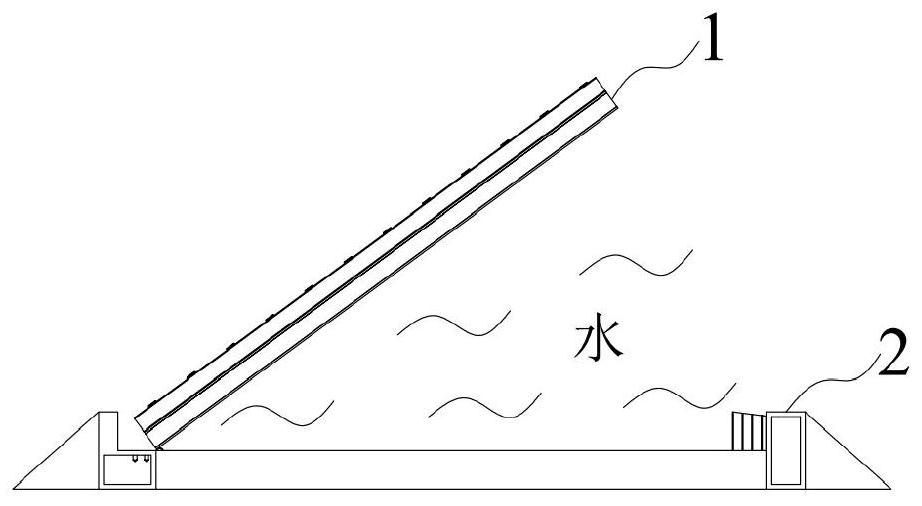

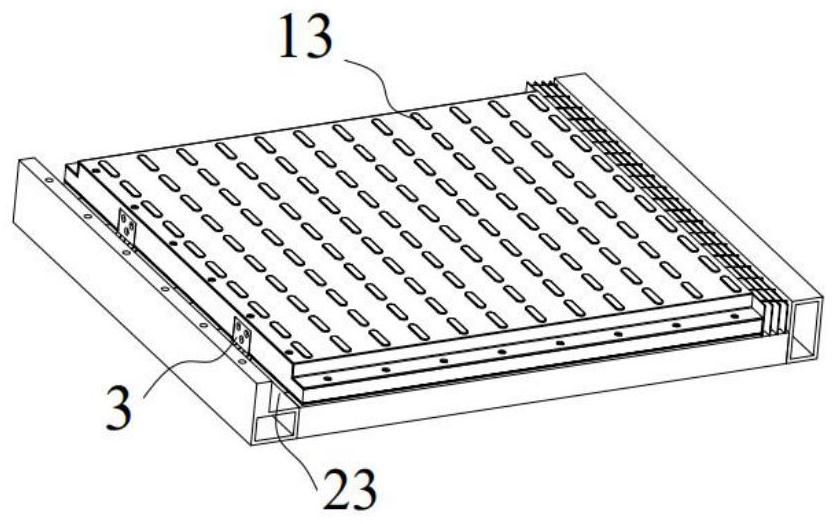

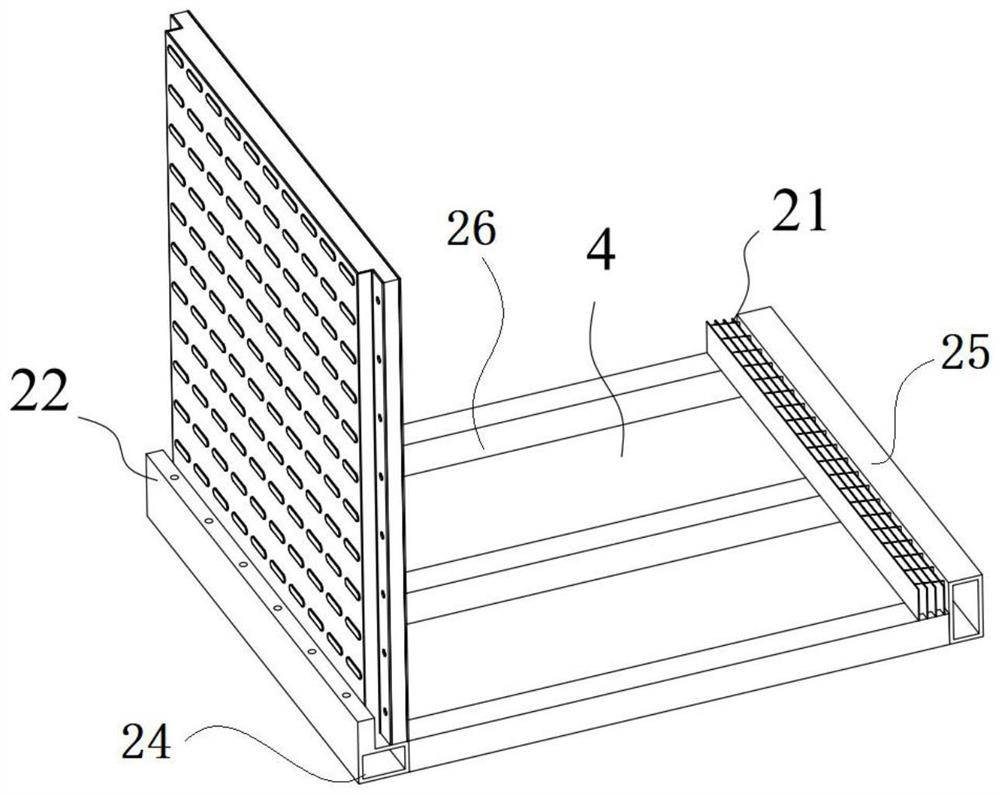

[0031] Embodiment 1: as Figure 1 to Figure 8As shown, according to the embodiment of the present invention, an automatic water retaining panel is provided. The water retaining panel is composed of a plurality of water retaining units sequentially connected. The water retaining unit includes: a base 2, the base 2 includes a water storage chamber 4; Water plate 1, one end of the water retaining plate 1 is hinged with the base 2 through the hinge 3, when the water in the water storage chamber 4 is full, the water retaining plate 1 can rotate around the hinge 3 under the action of buoyancy, thereby playing The function of water retaining; wherein, the adjacent water retaining boards 1 are connected by a connecting mechanism.

[0032] Preferably, the water retaining plate 1 includes a honeycomb core 111, a first outer layer plate 112 and a second outer layer plate 113; the first outer layer plate 112 is connected to the upper surface of the honeycomb core 111, and the second outer...

Embodiment 2

[0042] Such as Figure 9 As shown, the difference between this embodiment and Embodiment 1 is that the connecting mechanism includes a connecting piece 8, a third sealing strip 63 and a third screw 93, and the connecting piece 8 is symmetrically provided with two second installation grooves; The ends of the water retaining plate 1 honeycomb core 111 at the junction of the two water retaining units are integrally formed with mounting bosses 12, and the mounting bosses 12 of the two adjacent water retaining plates 1 honeycomb cores 111 respectively extend into two second In the installation groove, two third sealing strips 63 are arranged symmetrically outside the upper end and the lower end of the installation boss 12, and the third sealing strip 63 is located between the connector 8 and the water retaining plate 1, and the installation boss 12 and the third seal The strip 63 can completely fill the second installation groove; the third screw hole is symmetrically provided on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com