Silicon-based detector and manufacturing method thereof

A manufacturing method and detector technology, applied in the field of semiconductor detection, can solve the problems that semiconductor factories and research institutions are difficult to realize, and achieve the effects of improving depletion voltage and breakdown voltage, high gain, and increasing depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] An exemplary embodiment of the present disclosure will be described in more detail below with reference to the accompanying drawings. Although the exemplary embodiments of the present disclosure are shown, it is understood that the present disclosure can be implemented in various forms without limitation. Instead, these embodiments are provided to be more thoroughly understood to disclose the present disclosure, and can communicate the scope of the present disclosure to those skilled in the art.

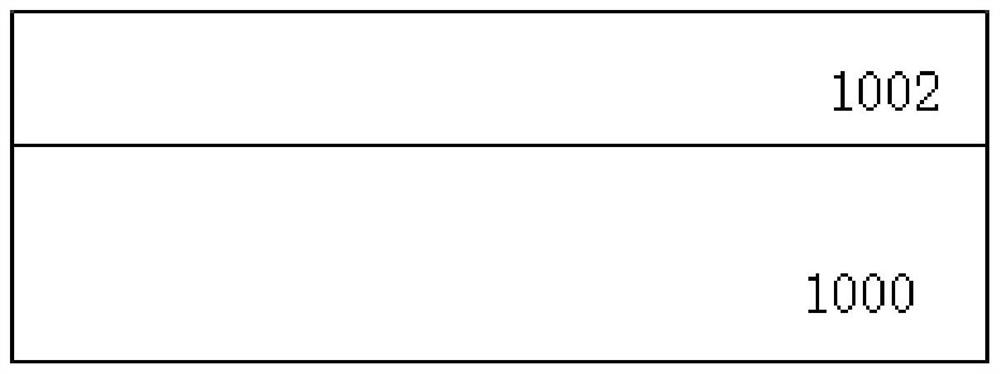

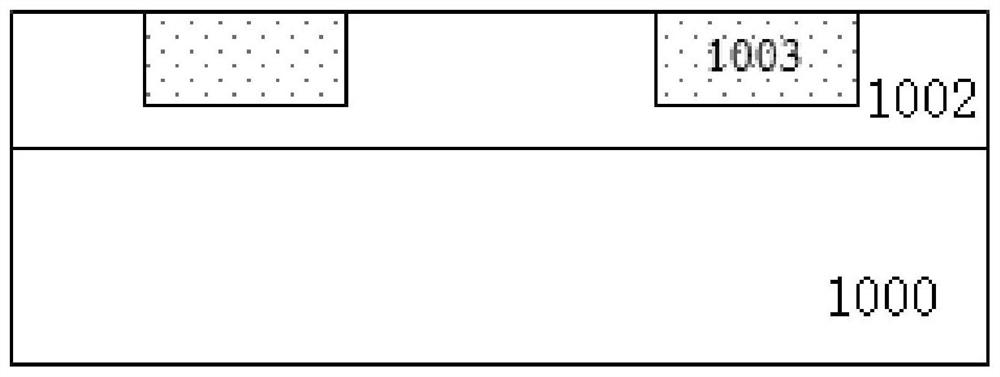

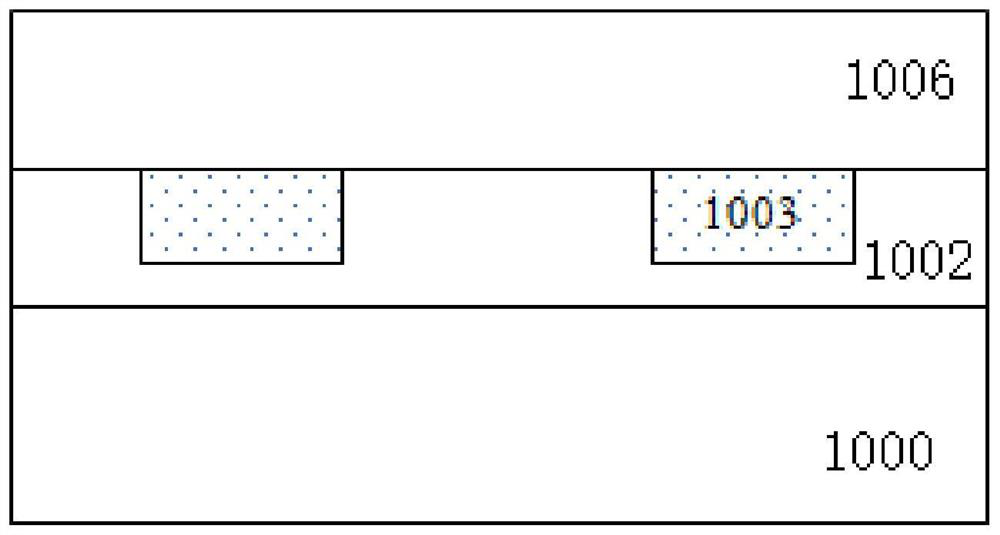

[0023] Figure 1I A portion longitudinal cross-sectional view of a silicon-based detector is shown in the present invention.

[0024] refer to Figure 1I As shown, a device structural layer is formed on the substrate 1000.

[0025] In an embodiment of the invention, the substrate 1000 can be a p-type high-doped substrate, and the doped concentration can be in 1e18 ~ 1e21cm. -3 In the range.

[0026] Continue reference Figure 1I As shown, the absorbing layer 1007, the gain layer 100...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com