High-power millimeter wave matching load

A matching load and millimeter wave technology, applied in the direction of waveguide devices, circuits, electrical components, etc., can solve the problems of increased reflected wave power, increased system, damage, etc., to reduce reflected wave power, reduce ignition probability, and reduce manufacturing cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

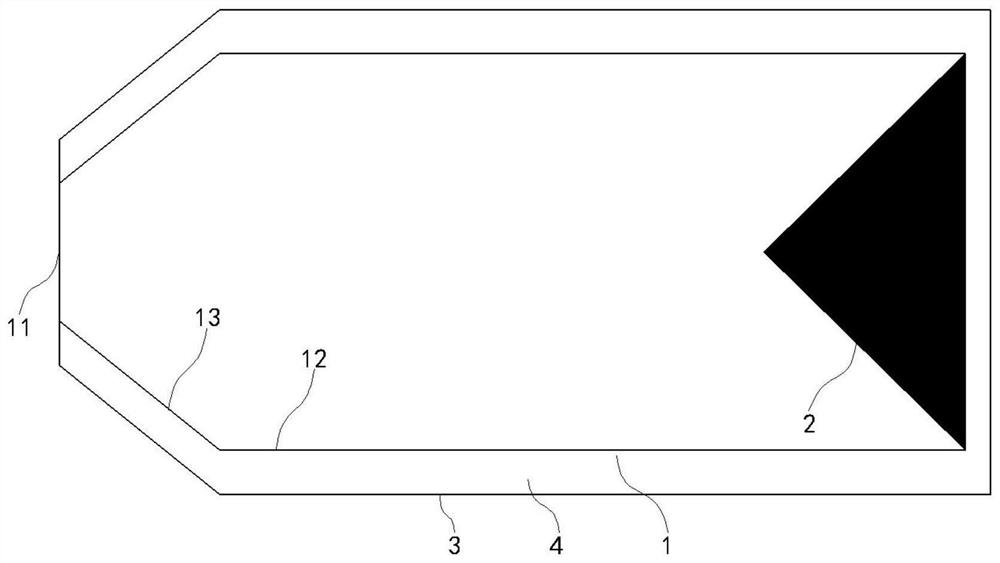

[0048] Such as figure 1 As shown, a high-power millimeter-wave matching load in this embodiment includes a stainless steel load body 1 with a cavity, and the cavity includes a reflection cavity 13 and an absorption cavity 12;

[0049] The beam entrance 11 is set on the load body 1, and the beam enters the cavity through the beam entrance 11;

[0050] The conical mirror 2 is arranged at the other end of the cavity relative to the beam entrance 11, and has a mirror surface facing the inner wall of the absorption cavity 12, so as to reflect the incident microwave beam to the inner wall of the absorption cavity 12;

[0051] The shape of the absorption cavity 12 is cylindrical, and it is located on one side of the reflector 2 for absorbing and reflecting the microwave beam reflected from the reflector 2;

[0052] The reflective cavity 13 is arranged at the front end of the absorbing cavity 12. The reflective cavity 13 is in the shape of a truncated cone and has a reflective cavit...

Embodiment 2

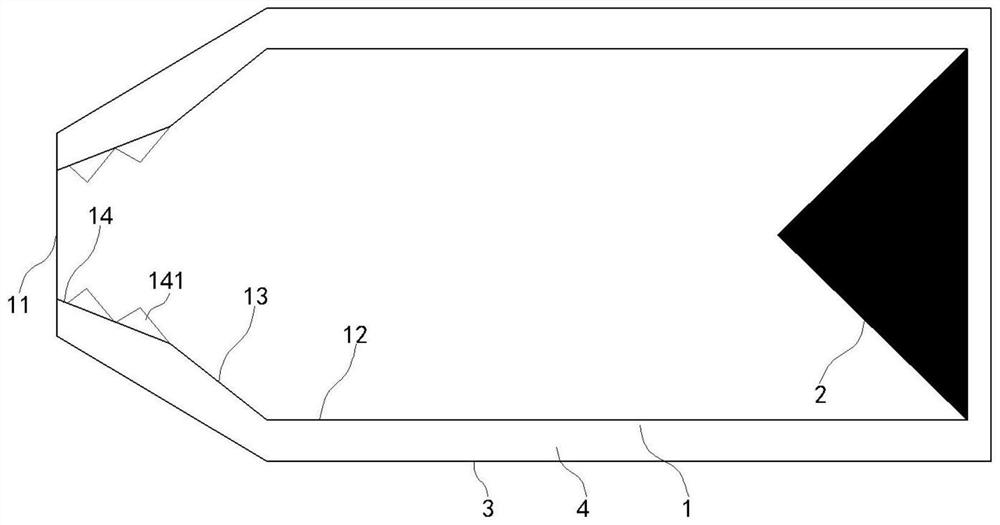

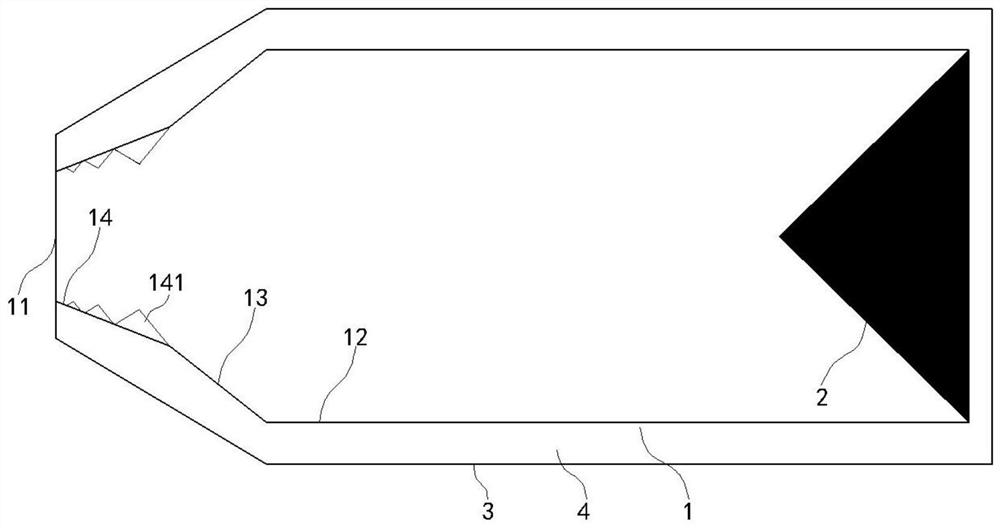

[0056] Such as figure 2 As shown, a high-power millimeter-wave matching load in this embodiment includes a stainless steel load body 1 with a cavity, and the cavity includes a pre-absorption section 14, a reflection cavity 13 and an absorption cavity 12 in turn, and the pre-absorption section 14 setting the toothed structure 141;

[0057] Such as Figure 5 As shown, the pre-absorption section 14 is trumpet-shaped, and the angle α between the pre-absorption section 14 and the horizontal plane is smaller than the angle β between the reflection cavity surface and the horizontal plane;

[0058] The beam entrance 11 is set on the load body 1, and the beam enters the cavity through the beam entrance 11;

[0059] The conical mirror 2 is arranged at the other end of the cavity relative to the beam entrance 11, and has a mirror surface facing the inner wall of the absorption cavity 12, so as to reflect the incident microwave beam to the inner wall of the absorption cavity 12;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com