An automated molding machine for making cement prefabricated components

A technology of prefabricated components and cement, applied in the direction of ceramic molding machines, ceramic molding cores, ceramic molding mandrels, etc., can solve the problems of heat generation, air holes, easy damage to the bottom surface of plate-shaped cement prefabricated components, etc., and achieve the goal of improving the molding quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

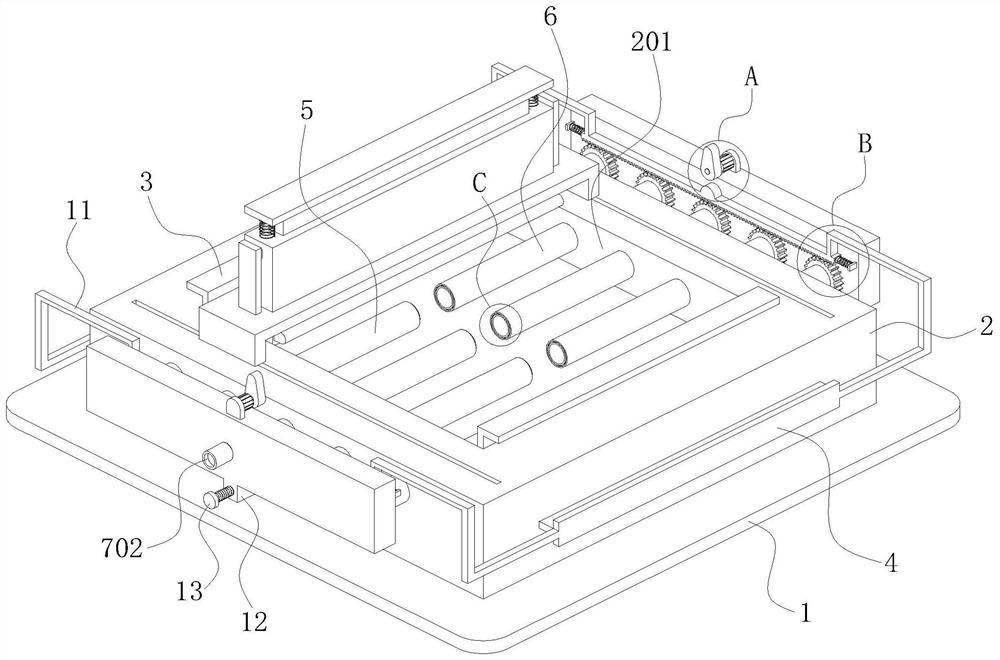

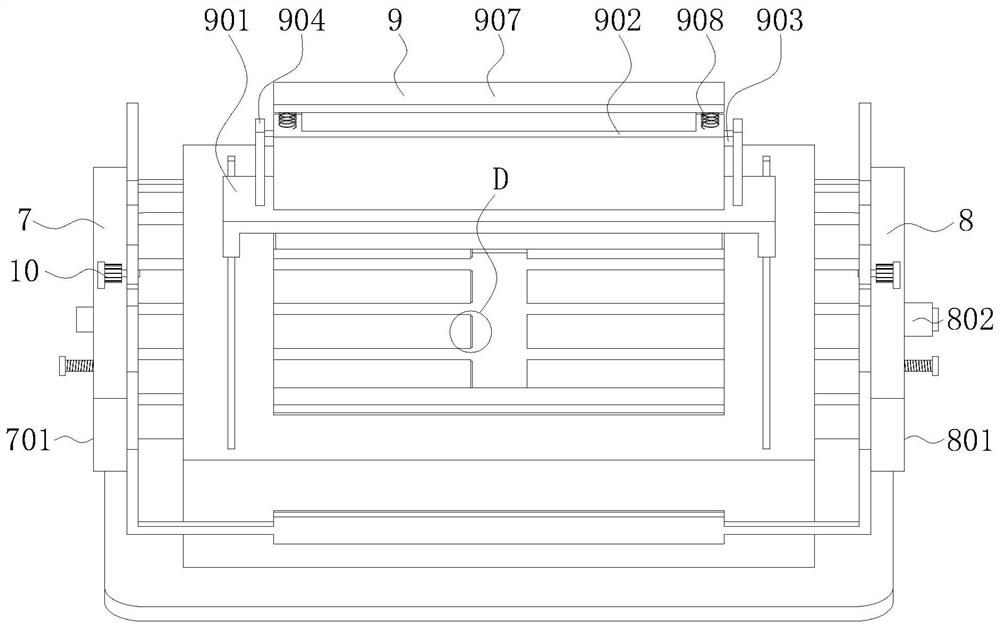

[0036] Embodiments of the present invention are described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered by the claims.

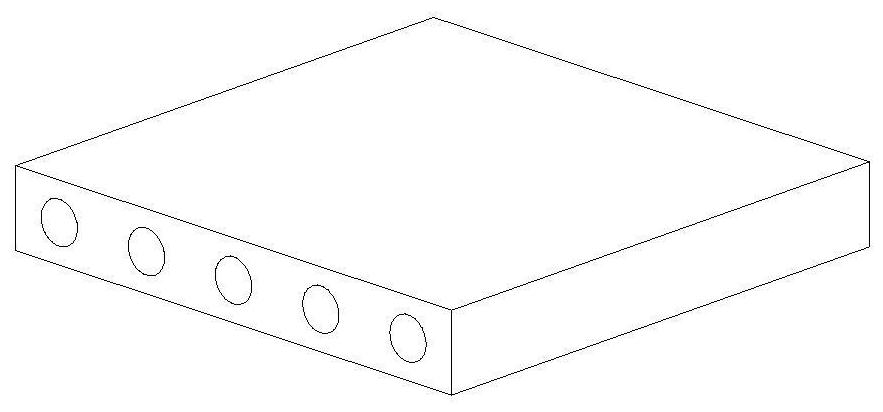

[0037] like Figure 2 to Figure 8 As shown, this embodiment provides an automatic molding machine for making cement prefabricated components, which is aimed at such as figure 1 The shown cement prefabricated component is manufactured, including a horizontal bottom plate 1, a mold box 2 is fixedly installed on the upper surface of the bottom plate 1, and a square groove 201 is vertically opened on the top surface of the mold box 2. The front and rear side walls of the square groove 201 are vertically slidably fitted with a side template 3, and the front and rear side walls of the mold box 2 are horizontally slidably fitted with a bottom template 4 that penetrates the mold box 2. The bottom surface of the bottom template 4 is connected to the square groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com