Small lug buckling device for glove packaging machine

A packaging machine and glove technology, applied in packaging, etc., can solve problems such as low efficiency, unsatisfactory use requirements, and high packaging error rate, and achieve the effects of expanding the scope of use, improving convenience, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

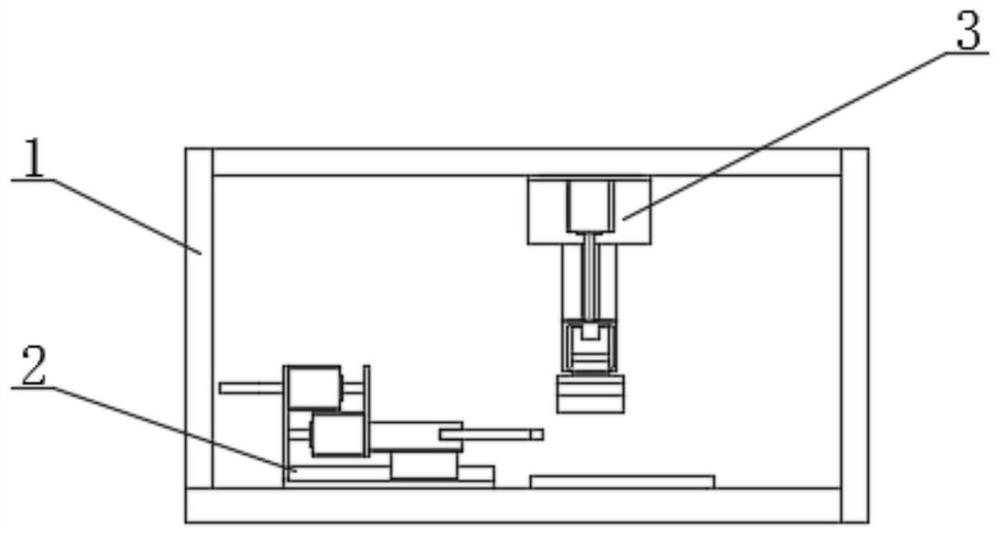

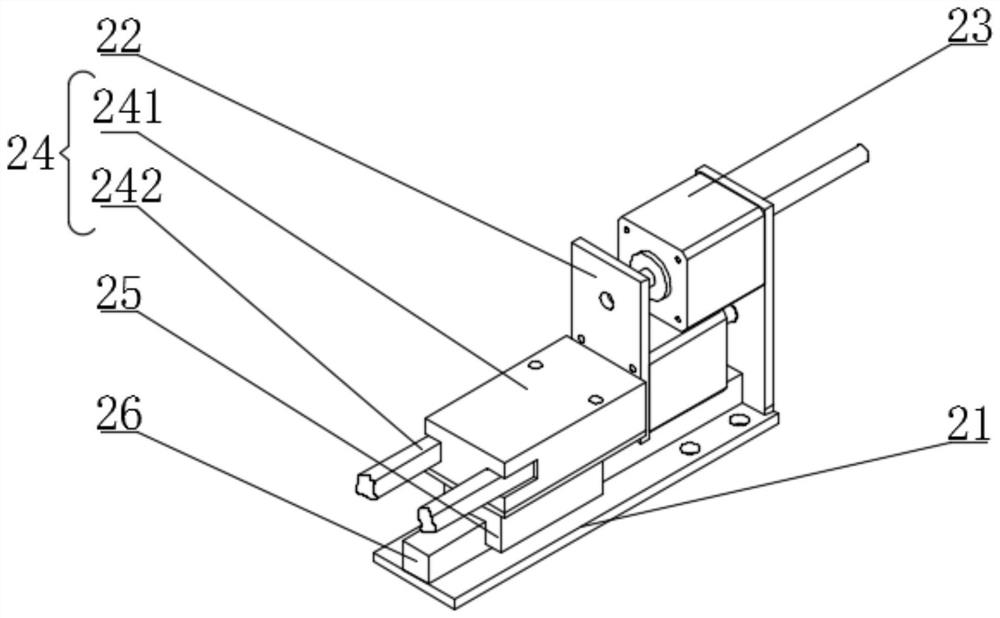

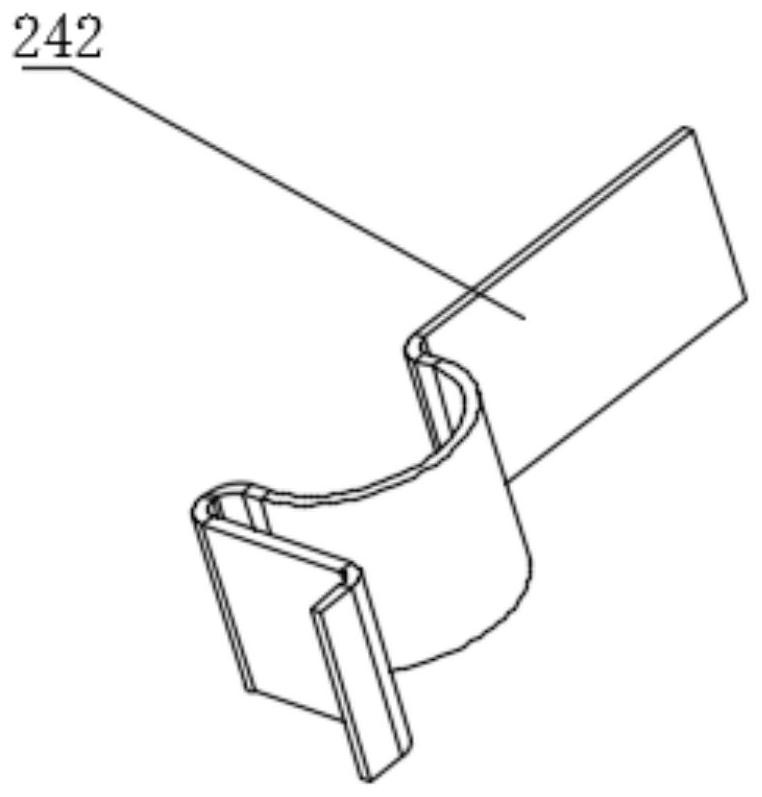

[0030] see Figure 1-6, the present invention provides a technical solution: a buckle small ear device for a glove packaging machine, including a fixed frame 1, a conveyor is fixedly installed at the bottom of the inner wall of the fixed frame 1; an ear buckle mechanism 2, and the ear buckle mechanism 2 includes a fixing plate 21. The moving plate 22, the first screw motor 23 and the mechanical claw 24, the bottom of the fixed frame 1 is fixedly installed on one side of the conveyor with a fixed plate 21, and the top of one side of the fixed plate 21 is fixed by a bracket A first screw motor 23 is installed, and the output end of the first screw motor 23 is fixedly equipped with a moving plate 22, and one side of the bottom of the moving plate 22 is fixedly equipped with a mechanical claw 24, and the mechanical claw 24 includes a controller 241 and jaws 242, and a controller 241 is fixedly installed on one side of the bottom of the moving plate 22, and jaws 242 are fixedly ins...

Embodiment 2

[0032] As a preferred solution of Embodiment 1, the pressure sensor 4 is fixedly installed in the center of the bottom of the lower pressure plate 34 through a groove, and the pressure sensor 4 is electrically connected to the single-chip microcomputer 5, and the cross section of the lower pressure plate 34 is The structure of "几" can play the role of adjusting and positioning the packaging box. If there are deviations in some positions of the packaging box conveyed from the conveyor, the position adjustment can be realized through the lower pressing plate 34, so that the packaging box and the buckle ear mechanism 2 correspond to each other. The pressure sensor 4 can detect the pressure value between the lower pressing plate 34 and the packaging box, which can effectively avoid the large deformation caused by excessive downward pressure, which does not meet the requirements for subsequent engagement, and improves the accuracy of packaging. When the pressure sensor 4 detects Whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com