Printing paste and preparation method thereof

A printing color paste, deionized water technology, applied in the field of color paste, to achieve the effect of good fabric fiber affinity, solving color fastness, good color fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

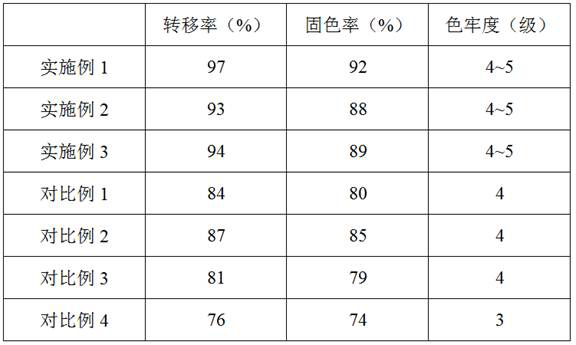

Examples

Embodiment 1

[0035] A kind of printing color paste, it is characterized in that, printing color paste is formed by mixing uniformly in 32 weight parts capsule membrane liquids by dripping of 68 weight parts capsule core liquids;

[0036] The capsule core liquid is prepared from the following raw materials in parts by weight: 8 parts of pigment, 6 parts of paste, 2 parts of thiourea, 1.2 parts of anti-staining salt, 0.5 part of defoamer, and 82.3 parts of deionized water.

[0037] The capsule liquid is a polyelectrolyte dispersant.

[0038] The pigment is C.I. Pigment Red 112.

[0039] The paste is composed of sepiolite and hydrolyzed sclerotinia in a weight ratio of 1:0.4.

[0040] The preparation method of described polyelectrolyte dispersant is:

[0041] S11. Stir 100 parts by weight of deionized water, 0.9 parts by weight of sodium bisulfite, and 0.9 parts by weight of isopropanol to obtain a first mixed solution;

[0042] S12, compounding ammonium persulfate and deionized water acco...

Embodiment 2

[0050] A kind of printing color paste, it is characterized in that, printing color paste is formed by mixing uniformly in 32 weight parts capsule membrane liquids by dripping of 68 weight parts capsule core liquids;

[0051]The capsule core liquid is prepared from the following raw materials in parts by weight: 2 parts of pigment, 2 parts of paste, 1 part of thiourea, 0.5 part of anti-staining salt, 0.4 part of defoamer, and 70 parts of deionized water;

[0052] The capsule liquid is a polyelectrolyte dispersant.

[0053] The pigment is C.I. Pigment Red 112.

[0054] The paste is composed of sepiolite and hydrolyzed sclerotinia in a weight ratio of 1:0.4.

[0055] The preparation method of described polyelectrolyte dispersant is:

[0056] S11. Stir 100 parts by weight of deionized water, 0.9 parts by weight of sodium bisulfite, and 0.9 parts by weight of isopropanol to obtain a first mixed solution;

[0057] S12, compounding ammonium persulfate and deionized water according...

Embodiment 3

[0065] A kind of printing color paste, it is characterized in that, printing color paste is formed by mixing uniformly in 32 weight parts capsule membrane liquids by dripping of 68 weight parts capsule core liquids;

[0066] The capsule core liquid is prepared from the following raw materials in parts by weight: 5 parts of pigment, 4 parts of paste, 1.2 parts of thiourea, 0.8 part of anti-staining salt, 0.6 part of defoamer, and 85 parts of deionized water;

[0067] The capsule liquid is a polyelectrolyte dispersant.

[0068] The pigment is C.I. Pigment Red 112.

[0069] The paste is composed of sepiolite and hydrolyzed sclerotinia in a weight ratio of 1:0.4.

[0070] The preparation method of described polyelectrolyte dispersant is:

[0071] S11. Stir 100 parts by weight of deionized water, 0.9 parts by weight of sodium bisulfite, and 0.9 parts by weight of isopropanol to obtain a first mixed solution;

[0072] S12, compounding ammonium persulfate and deionized water accor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com