Debris flow pile group protection structure and system based on energy conversion enhancement mechanism

A technology of strengthening mechanism and energy conversion, which is applied in the direction of infrastructure engineering, protective equipment, sheet pile walls, etc., can solve the problems of affecting the blocking effect, the design height of single pile is small, and the risk of single pile damage is large, so as to achieve good protection effect, The effect of enhancing the protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

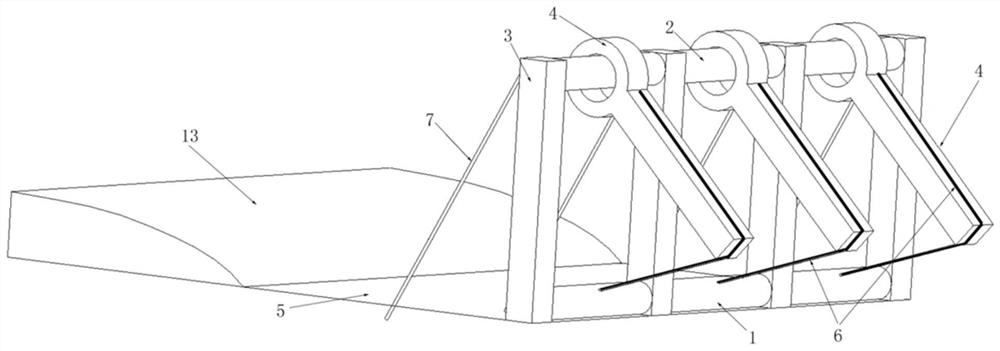

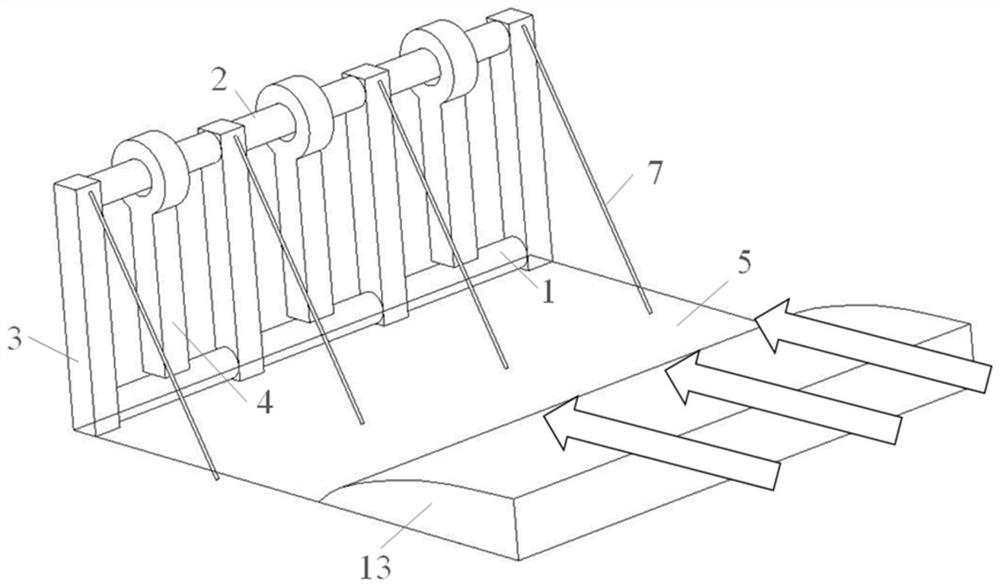

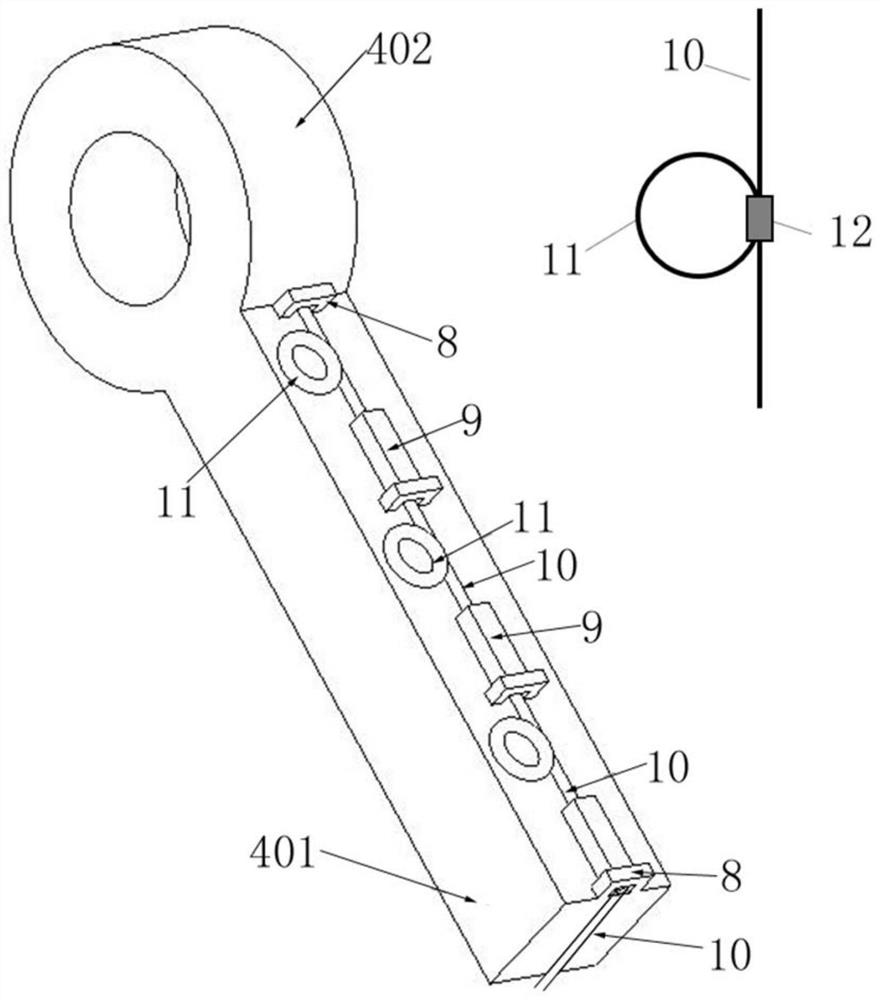

[0032] A protective structure of debris flow pile groups based on energy conversion enhancement mechanism, used to block debris flow13, such as figure 1 and figure 2 As shown, including ground beam 1, suspension beam 2, fixed pile 3 and rotating pile 4, ground beam 1 is installed on the ground 5, suspension beam 2 is parallel to ground beam 1, fixed pile 3 is perpendicular to suspension beam 2 and ground beam 1, fixed pile The two ends of 3 are fixedly connected with the suspension beam 2 and the ground beam 1 respectively, the upper end of the rotary pile 4 is rotatably connected with the suspension beam 2, and the rotary pile 4 and the ground beam 1 are connected by an energy-dissipating anchor cable structure 6 .

[0033] On the one hand, the top of the fixed pile 3 is fixedly connected with the suspension beam 2, and the top of the fixed pile 3 is provided with an anchor 7, and the other end of the anchor 7 is connected to the ground 5 for anchoring, and the anchor 7 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com