Intelligent detection equipment and process for cross-flow fan

A technology for cross-flow fans and equipment, applied in mechanical equipment, components of pumping devices for elastic fluids, pump control, etc., can solve the problems of innovative solutions, dynamic balance detection and adjustment of production processes, and achieve savings. Labor time, convenient maintenance and technology upgrade, the effect of promoting improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

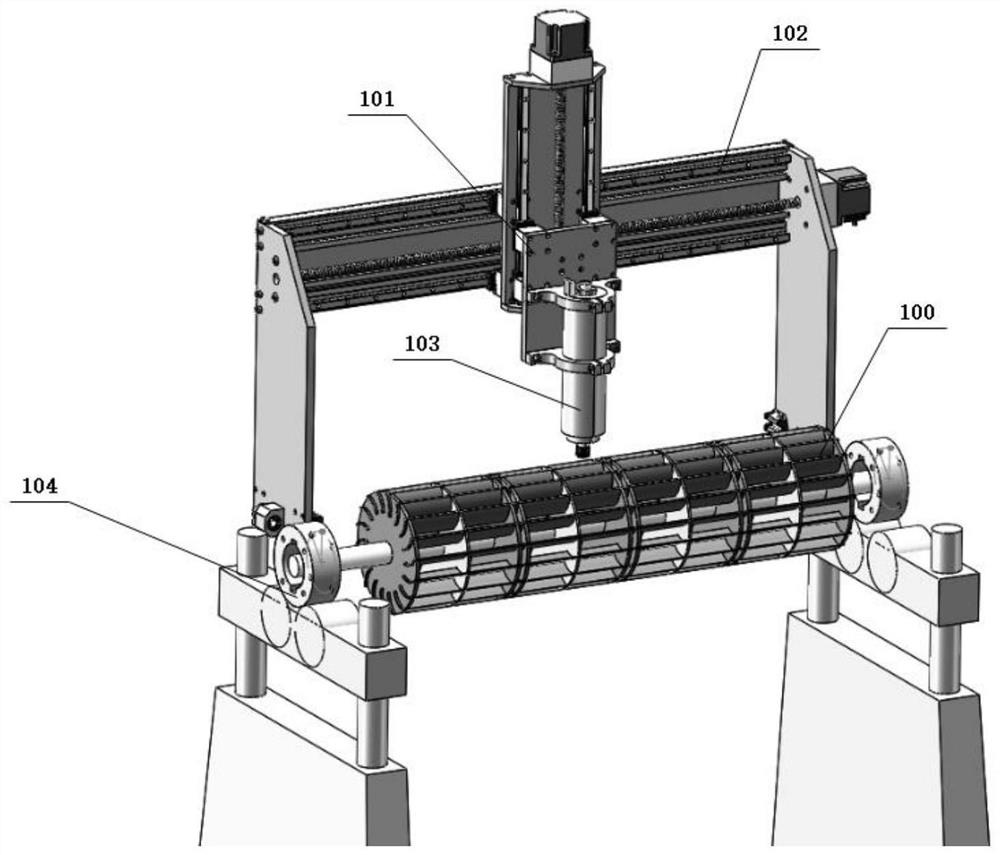

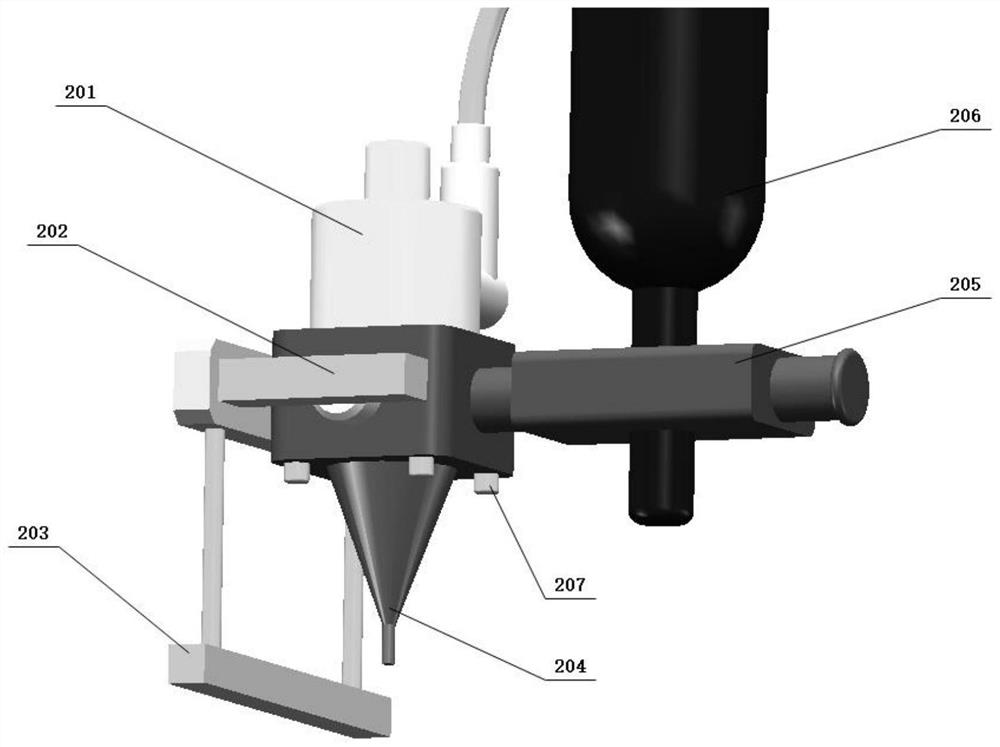

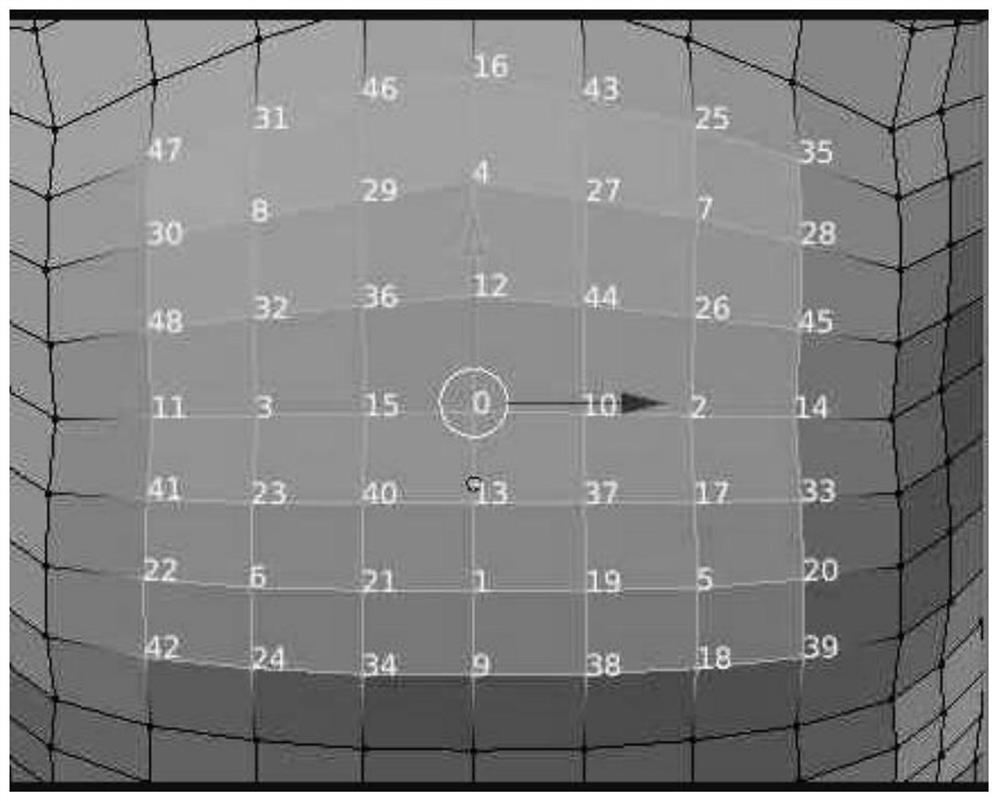

[0032] An intelligent production equipment for a cross-flow fan, the production equipment includes a dynamic balance detector, a counterweight device, a moving slide rail assembly and a control system; the dynamic balance detector uses rollers to drive the workpiece to be tested, and performs Dynamic balance test, analyze the unbalance of the workpiece under test and record it in digital form, and feed back the test result in visual form; The counterweight is adjusted at a designated position so that the measured workpiece reaches the dynamic balance standard; the mobile slide rail assembly is connected and installed with the counterweight device, and is used to drive the counterweight device to perform displacement and angle adjustment in multiple directions; The control system is connected to and controls the dynamic balance detector, the counterweight device and the moving slide rail assembly, so as to realize the automatic dynamic balance detection and adjustment process; ...

Embodiment 2

[0046] This embodiment should be understood as at least including all the features of any one of the preceding embodiments, and further improved on the basis of it; an intelligent production equipment for a cross-flow fan, the production equipment includes a dynamic balance detector, a counterweight device, Mobile slide rail assembly and control system; the dynamic balance detector uses rollers to drive the workpiece to be tested, and performs a dynamic balance test at a standard test speed, analyzes the unbalance of the workpiece to be tested and records it in digital form, and visually The test result is fed back in the form; the counterweight device adopts the form of dispensing to increase the counterweight, and adjusts the counterweight to the specified position of the specified blade of the workpiece under test, so that the workpiece under test reaches the dynamic balance standard; the mobile slide rail assembly and The counterweight device is connected and installed, and...

Embodiment 3

[0060]This embodiment should be understood as at least including all the features of any one of the preceding embodiments, and further improved on the basis of it: a cross-flow fan intelligent production equipment, the production equipment includes a dynamic balance detector, a counterweight device, Mobile slide rail assembly and control system; the dynamic balance detector uses rollers to drive the workpiece to be tested, and performs a dynamic balance test at a standard test speed, analyzes the unbalance of the workpiece to be tested and records it in digital form, and visually The test result is fed back in the form; the counterweight device adopts the form of dispensing to increase the counterweight, and adjusts the counterweight to the specified position of the specified blade of the workpiece under test, so that the workpiece under test reaches the dynamic balance standard; the mobile slide rail assembly and The counterweight device is connected and installed, and is used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com