Complete formula feed for ruminant fattening cattle

A compound feed and ruminant technology, applied to animal feed, animal feed, additional food elements, etc., can solve the problems of ruminants consume a lot of energy, forage quality control is difficult, feed mildew and deterioration, etc., to prevent energy loss and waste, improve Production performance, moisture-proof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

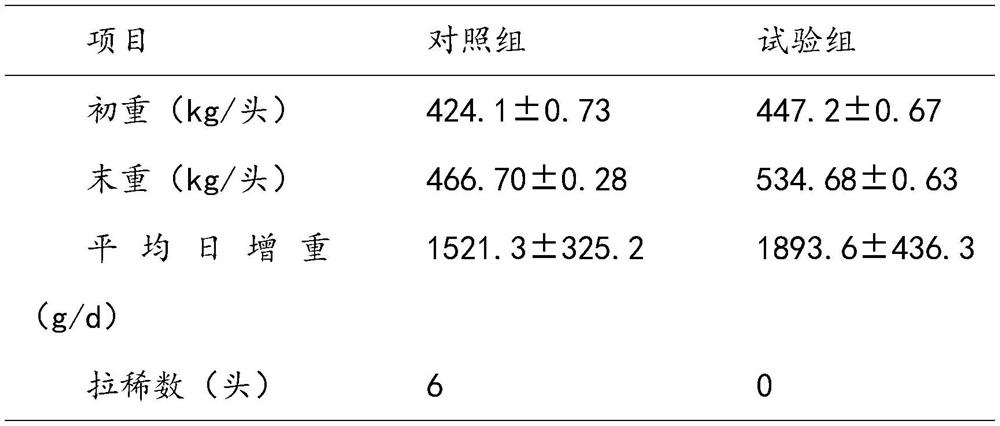

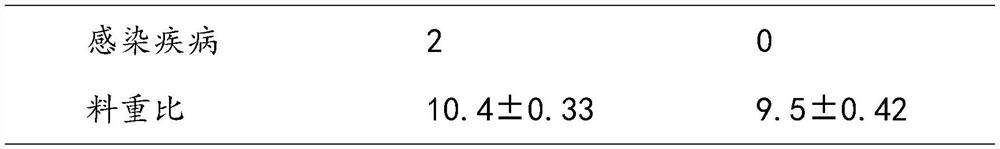

Examples

Embodiment 1

[0029] Embodiment 1: 1) various raw materials are taken according to the formula ratio, and corn, wheat bran, puffed soybean, corn germ meal, alfalfa grass powder, and chaff are finely pulverized;

[0030] 2) 10 parts of finely crushed corn, 20 parts of wheat bran, 2 parts of puffed soybean, 15 parts of corn germ meal, 15 parts of alfalfa powder, 15 parts of chaff, 0.5 part of calcium hydrogen phosphate, 0.1 part of table salt, compound pre- Mix 1 part and mix well;

[0031] 3) Place the mixed material at a pressure of 0.25 and a granulation temperature of 80°C.

[0032] 4) After preparation, cool and granulate, and collect the container.

Embodiment 2

[0033] Embodiment 2: various raw materials are taken according to the formula ratio, and corn, wheat bran, puffed soybeans, corn germ meal, alfalfa grass powder, and rice husk are finely pulverized;

[0034] 2) 12 parts of finely crushed corn, 22 parts of wheat bran, 3 parts of puffed soybean, 18 parts of corn germ meal, 16 parts of alfalfa powder, 18 parts of chaff, 0.8 part of calcium hydrogen phosphate, 0.2 part of table salt, compound pre- Mix 1 part of the mixture evenly, 1 part of meat powder, and 1 part of multivitamins;

[0035] 3) Place the mixed material at a pressure of 0.28MPa and a granulation temperature of 88°C.

[0036] 4) After preparation, cool and granulate, and collect the container.

Embodiment 3

[0037] Embodiment three: various raw materials are taken according to the formula ratio, and corn, wheat bran, puffed soybeans, corn germ meal, alfalfa grass powder, and rice husk are finely pulverized;

[0038] 2) 20 parts of finely crushed corn, 26 parts of wheat bran, 4 parts of puffed soybeans, 19 parts of corn germ meal, 19 parts of alfalfa powder, 19 parts of chaff, 1.8 parts of calcium hydrogen phosphate, 0.6 parts of table salt, compound pre- Mix 2.5 parts of the mixture evenly, 2.5 parts of meat powder, and 2 parts of multivitamins;

[0039] 3) Place the mixed material at a pressure of 0.31MPa and a granulation temperature of 90°C.

[0040] 4) After preparation, cool and granulate, and collect the container.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com