Catalytic cracking catalyst containing rare earth Y-type molecular sieve

A catalytic cracking, molecular sieve technology, applied in molecular sieve catalysts, catalytic cracking, physical/chemical process catalysts, etc., can solve problems such as complex solid-state ion exchange process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1 Preparation of a rare earth NAY molecular sieve in a catalytic cracking catalyst of the present invention will be described.

[0031] Take 100G NAY molecular sieve (China Petrochemical Catalyst Corporation Changling Branch, burns 74.1%, crystallinity of 89.3%, lower) and 1800 g of deionized water mixed beat, 10g of ammonium chloride solid, stir well to 70 ° C , Mix with a constant temperature for 2 h, filtration, washing, drying, add 20 ml of concentration of 357GRE 2 O 3 The chlorinated rare earth salt solution and 2 g of ammonium chloride were stirred up to 70 ° C and the pH of the slurry was adjusted to 4.5, and the temperature was stirred for 1 h with a dilute hydrochloric acid. After filtration, water washing, drying, externally applied pressure and added water, 500 ° C, an apparent pressure 0.3 MPa, and 100% water and thermofaked burn treatment for 2 h, to obtain a rare earth NAY molecular sieve sample, which is PDY-1.

[0032] Among the chemical composition...

Embodiment 2

[0044] Example 2 An preparation of a rare earth NAY molecular sieve in a catalytic cracking catalyst of the present invention will be described.

[0045] Take 100G NAY molecular sieve (China Petrochemical Catalyst Corporation Changling Branch, Crystal Cell 74.1%, crystallinity 89.3%, the same) and 1000 g of deionized water mixed, 5 g ammonium sulfate solid, stirred up to 80 ° C, Heat temperature was stirred for 2 h, filtered, washed, dry, dried, add 16 ml of concentration of 357GRE 2 O 3 The chlorinated rare earth salt solution and 8 g of ammonium chloride were stirred up, and the pH of the slurry solution was adjusted to 4.0, and the temperature was stirred at a constant temperature for 1.5 h.

[0046] After filtration, water washing, dry, externally applied pressure and add water, and pressurized water and hot roasting treatment at 430 ° C, an apparent pressure 0.8 MPa, 50% water vapor atmosphere, to obtain a rare earth NAY molecular sieve sample, recorded as PDY-2 .

[0047] Th...

Embodiment 3

[0059] Example 3 Preparation of a rare earth NAY molecular sieve in a catalytic cracking catalyst of the present invention.

[0060] Take 100 g of NAY molecular sieves and 2200 g of deionized water mixing, 20 g of ammonium sulfate solid, stirred up to 80 ° C, stirring at a constant temperature 1.5 h, filtrate, washed, dry, dry, add 24 ml concentration of 357GRE 2 O 3 The chlorinated rare earth salt solution of / L is stirred up to 70 ° C and the pH of the slurry is adjusted to 3.5 with dilute hydrochloric acid, and the constant temperature is stirred for 1 h.

[0061] After filtration, water washing, dry, externally applied pressure and add water, 520 ° C, oxidative pressure 0.4 MPa, 100% water vapor atmosphere, pressure water, heat baked treatment 1.5 h, to obtain a rare earth NAY molecular sieve sample, recorded as PDY-3 .

[0062] In the chemical composition of PDY-3, the oxidized rare earth was 11.4% by weight.

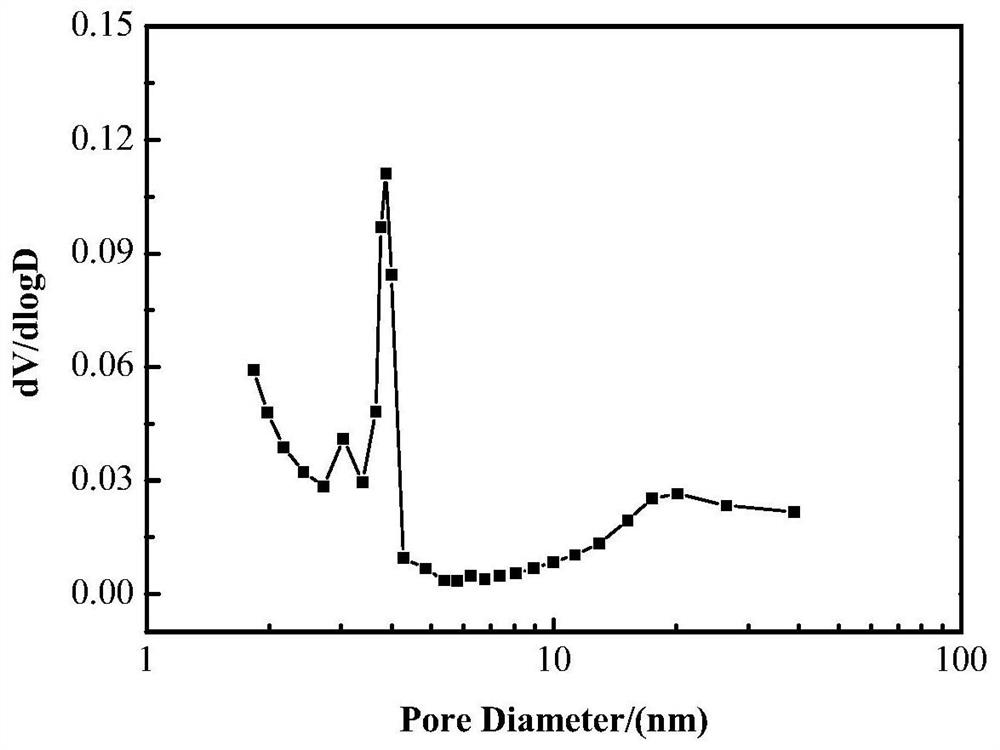

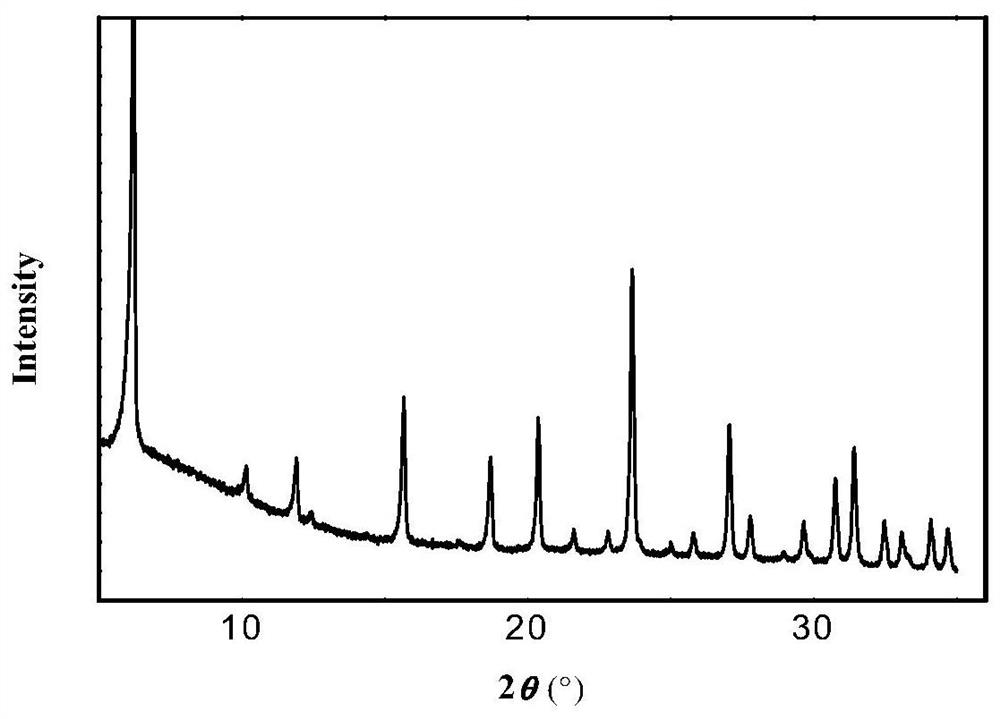

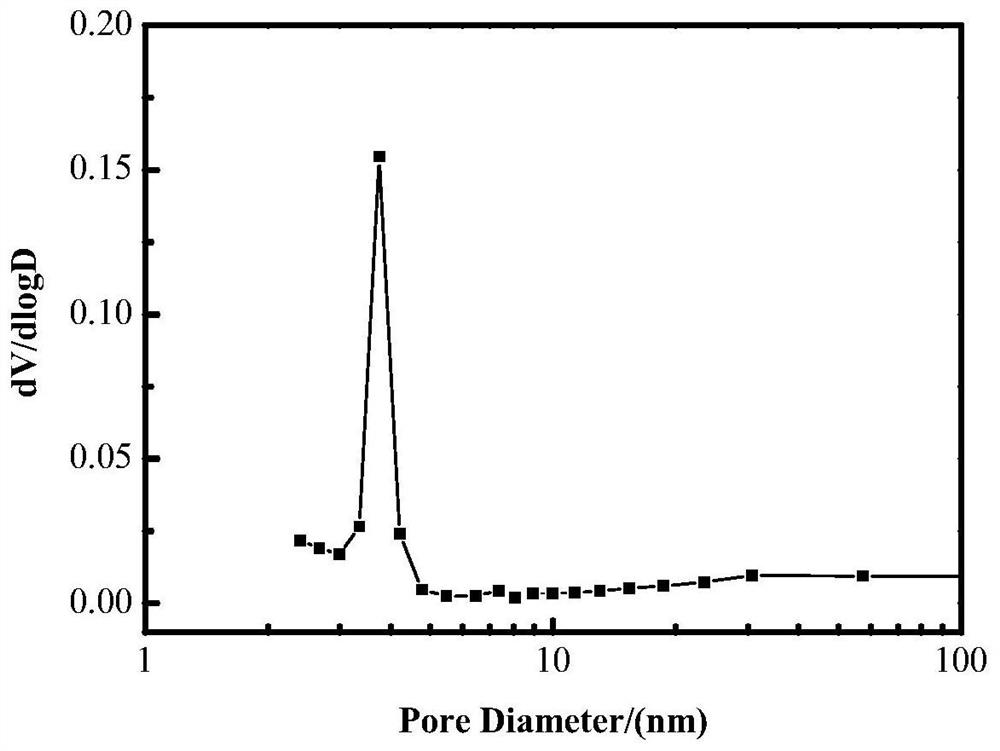

[0063] PDY-3 BJH aperture distribution curve and XRD spectrum ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com