Interpolation mechanism for laser scribing device and scribing device using the interpolation mechanism

A scribing device and interpolation technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of high price and lack of compatibility of electronic scanners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

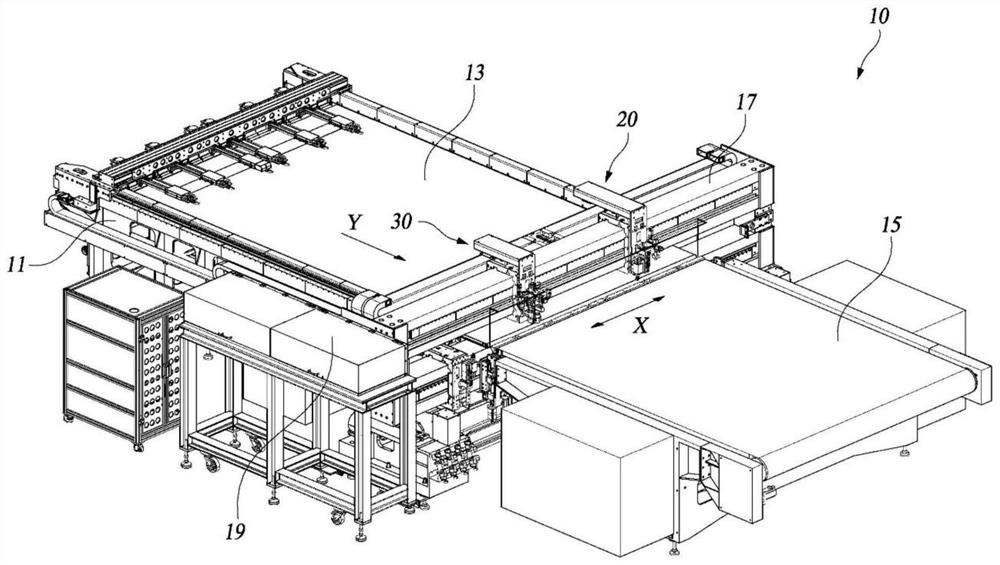

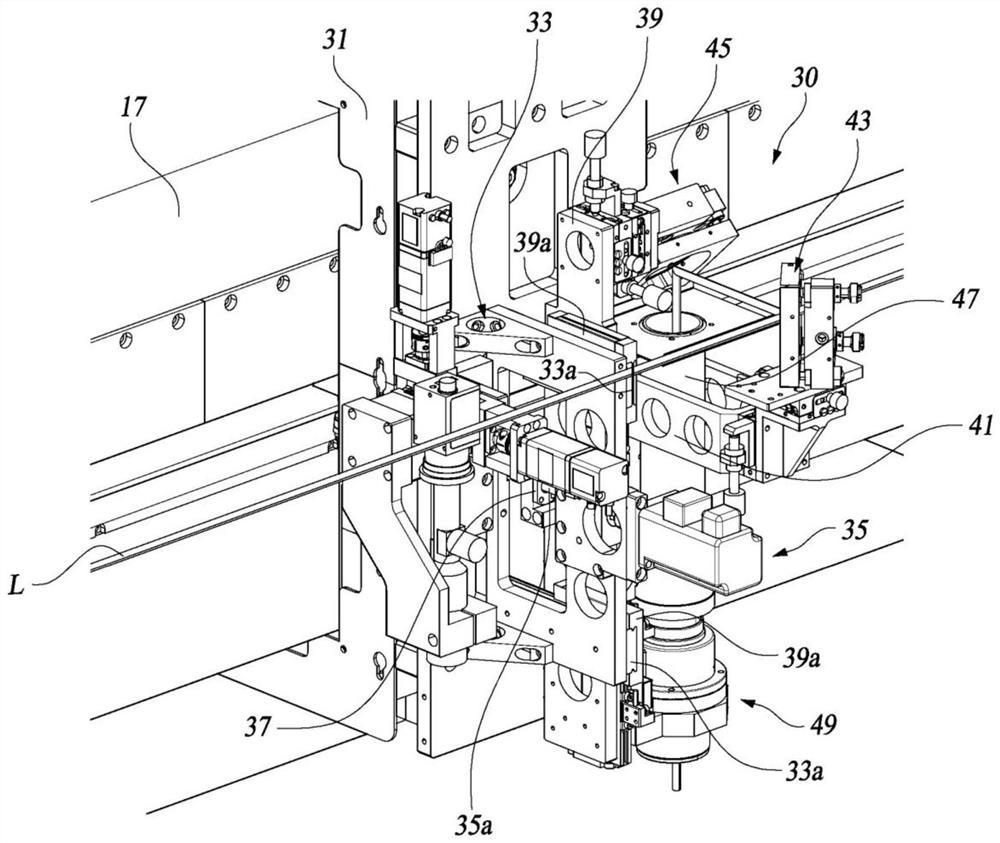

[0030] Next, an embodiment of the present invention will be described in more detail with reference to the drawings.

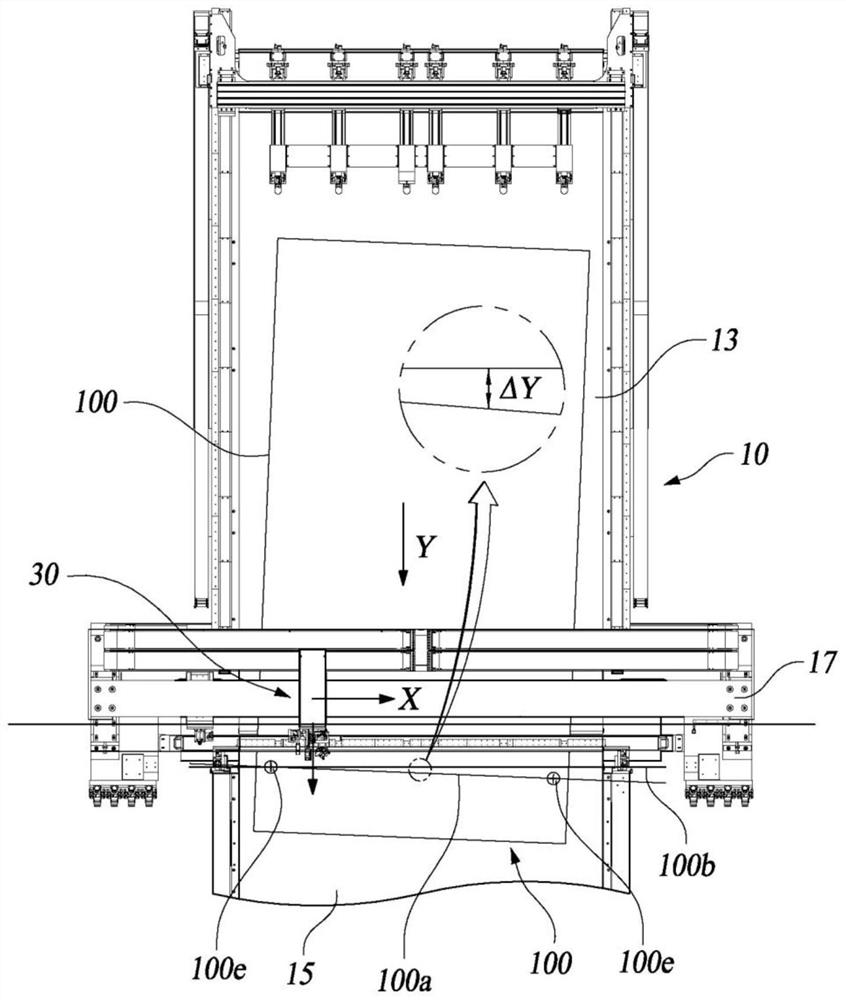

[0031] figure 1 It is a plan view for explaining the purpose and principle of laser beam irradiation position interpolation.

[0032] The basic purpose of performing interpolation is to form scribe lines at accurate positions on the brittle substrate 100 . That is, if figure 1 As shown, even if the first belt conveyor 13 moves horizontally in the Y direction and the brittle substrate 100 located at the lower part of the horizontal moving table 17 is in a skewed state, considering the degree of skewing, the light beam emitting part that moves in the X direction is also simultaneously Move in the Y direction.

[0033] Regarding this interpolation, the amount of deviation ΔY (in the Y direction along the X direction) between the virtual straight line 100a connecting the alignment mark 100e and the moving route 100b of the laser irradiation unit 30 itself is ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com