Preparation method and use of biomass-based superhydrophobic coating with durability and color diversity

A technology of super-hydrophobic coating and color coating, applied in coating, multi-color effect coatings, etc., can solve the problems of cumbersome manufacturing process, unfavorable large-scale production, etc., and achieve the effect of good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

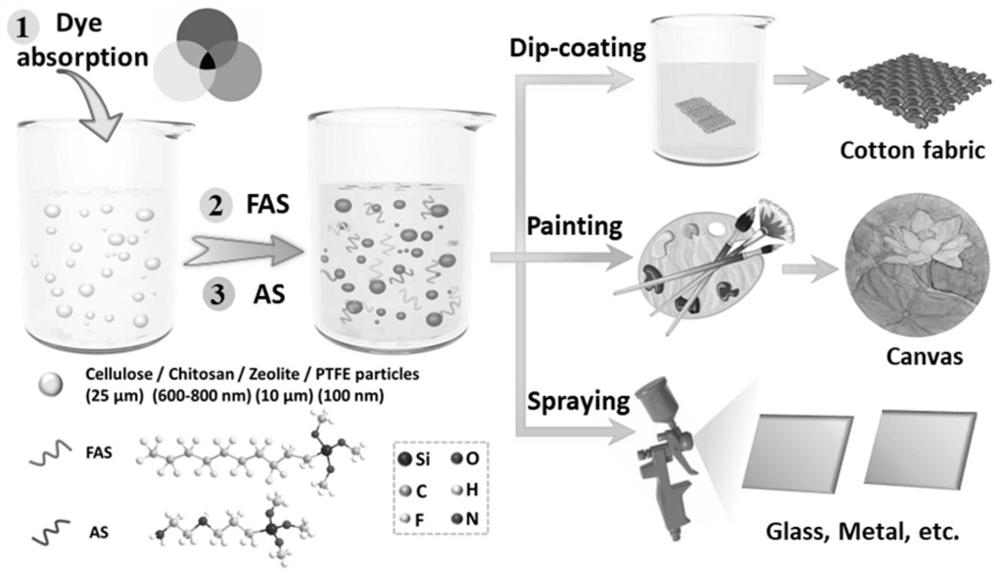

[0081] The preparation of embodiment 1 colored coating liquid and colored superhydrophobic coating

[0082] Usually, 0.6g, 0.4g, 0.3g and 0.7g of cellulose, chitosan, zeolite and PTFE were weighed and dispersed into a mixed solution of 30mL absolute ethanol and 5mL acetic acid. Then, a certain dye was added to the above solution, and stirred at 60° C. for 6 h to obtain a colored suspension. After that, 800 μL of FAS was added dropwise to the above solution, and stirred for 2 hours. Then, 2 mL of AS was added dropwise and stirred continuously for 3 h to obtain a colored coating solution. Different substrates such as glass, aluminum sheet, ceramic tile and wood were coated by spraying the colored coating liquid (2 mL) using a spray gun from a distance of 10 cm in the vertical direction. Cotton fabrics can be dipped into the color suspension. Finally, the colored coating was obtained by heating the coating material in an oven at 80 °C for 5 h, followed by drying at 110 °C for 30...

Embodiment 2

[0086] Research and characterization of embodiment 2 colored superhydrophobic coating

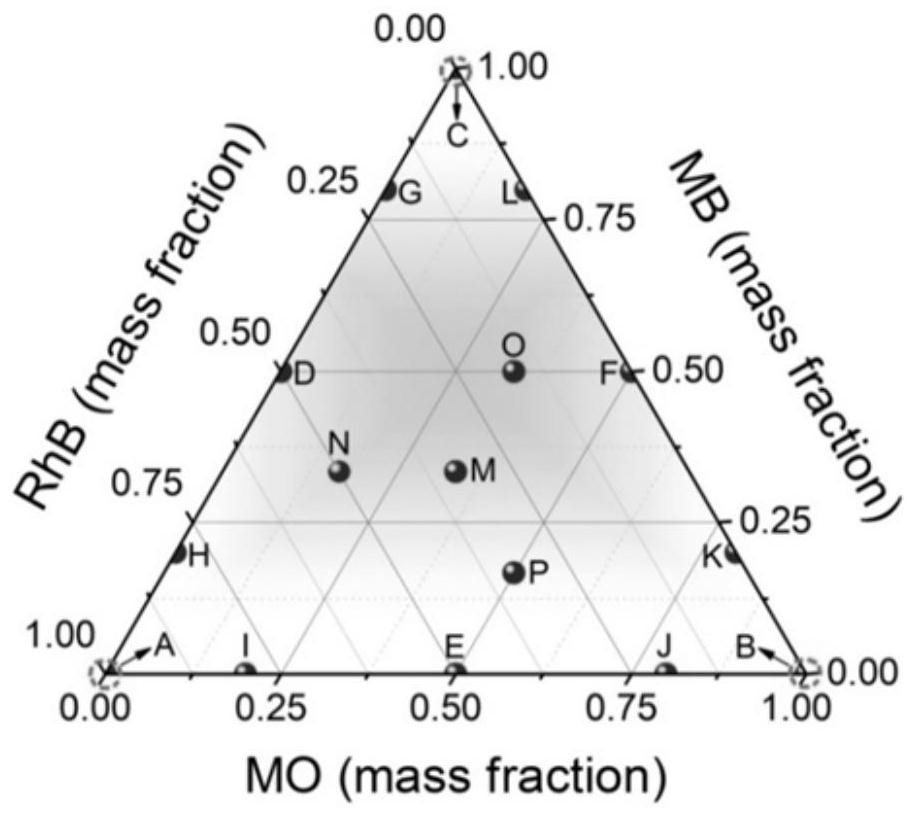

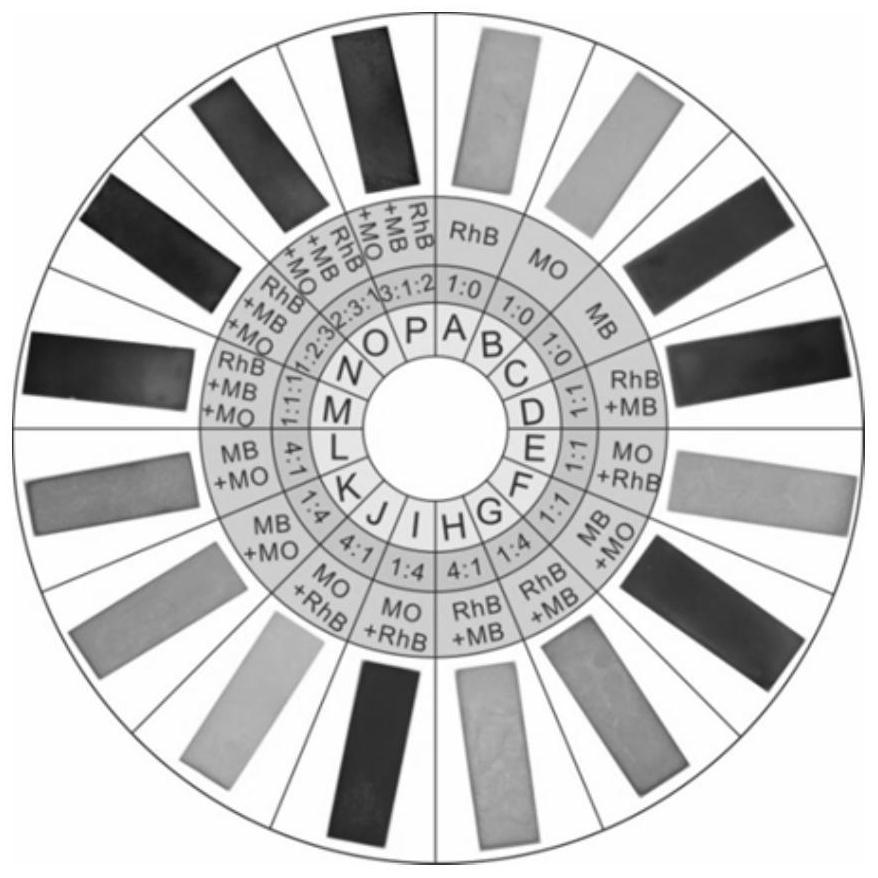

[0087] According to the method of Example 1, by changing the total mass of the dyes while keeping the mass ratio constant, a series of coatings with color gradients can be obtained. For example, by keeping the mass ratios as 1:0 (RhB, point A), 1:0 (MB, point C), 1:1 (MB:MO, point F), 1:4 (MO:RhB, point I) Four color gradients of pink, blue, green and red can be obtained ( Figure 4 ).

[0088] Unlike other literatures in which colors are generated by the interaction of particles with light waves, or by femtosecond electroplating on special metal surfaces, the color of our coatings is obtained by simple physisorption and is not limited by the materials used . In other words, the dyes in the solvent can be adsorbed on the surface of porous materials by directly using micro-nano particles such as zeolite as adsorbents. Different colors can be obtained by absorbing different dyes. It is w...

Embodiment 3

[0112] The preparation of embodiment 3 coating solution and superhydrophobic coating

[0113] Others are the same as in Example 1, and the components of the superhydrophobic coating are studied. The difference is that dyes are not included, and the preparation method does not include the process of preparing dyes into suspensions.

[0114] During the fabrication of the superhydrophobic coating, multilevel roughness structuring and polyfluorination methods were employed. Micro-nanoparticles of cellulose, chitosan, zeolite, and PTFE with micro / nano sizes of 25 μm, 400-800 nm, 10 μm, and 100 nm were used to construct hierarchical rough structures; mixing to remove certain components was tested. For example, to remove a certain component under the condition of the optimal ratio (cellulose / chitosan / zeolite / PTFE / FAS / AS─0.6g / 0.4g / 0.3g / 0.7g / 800μL / 2mL), the results are shown in the table 2.

[0115] Table 2 Exploration of different components.

[0116]

[0117] It can be seen fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com