Raw material fermentation equipment for industrial enzyme production

A fermentation equipment and raw material technology, which is applied in the field of high-efficiency industrial enzyme preparation, can solve the problems of uneven ratio of fermentation raw materials and discharge, splash adhesion, etc., and achieve the effect of reducing the uneven ratio of discharged raw materials and increasing the discharge speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] as attached figure 1 to attach Figure 5 Shown:

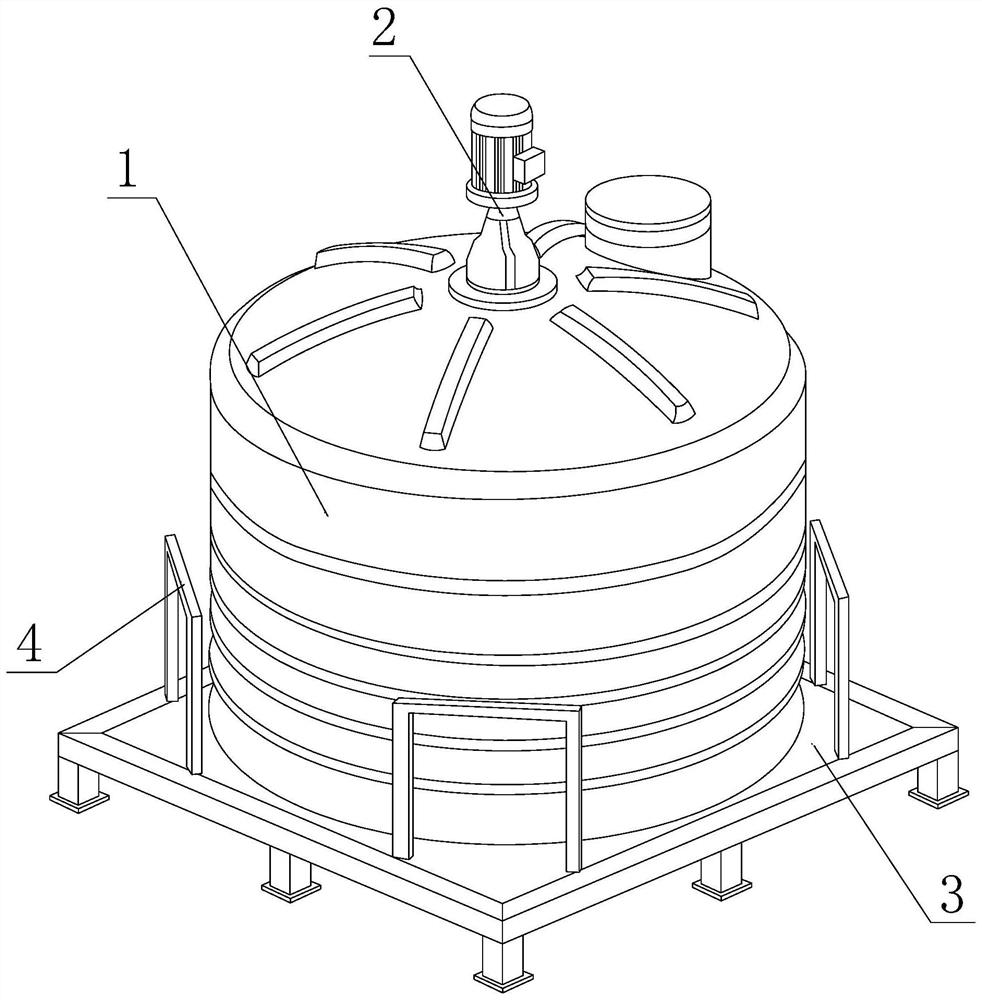

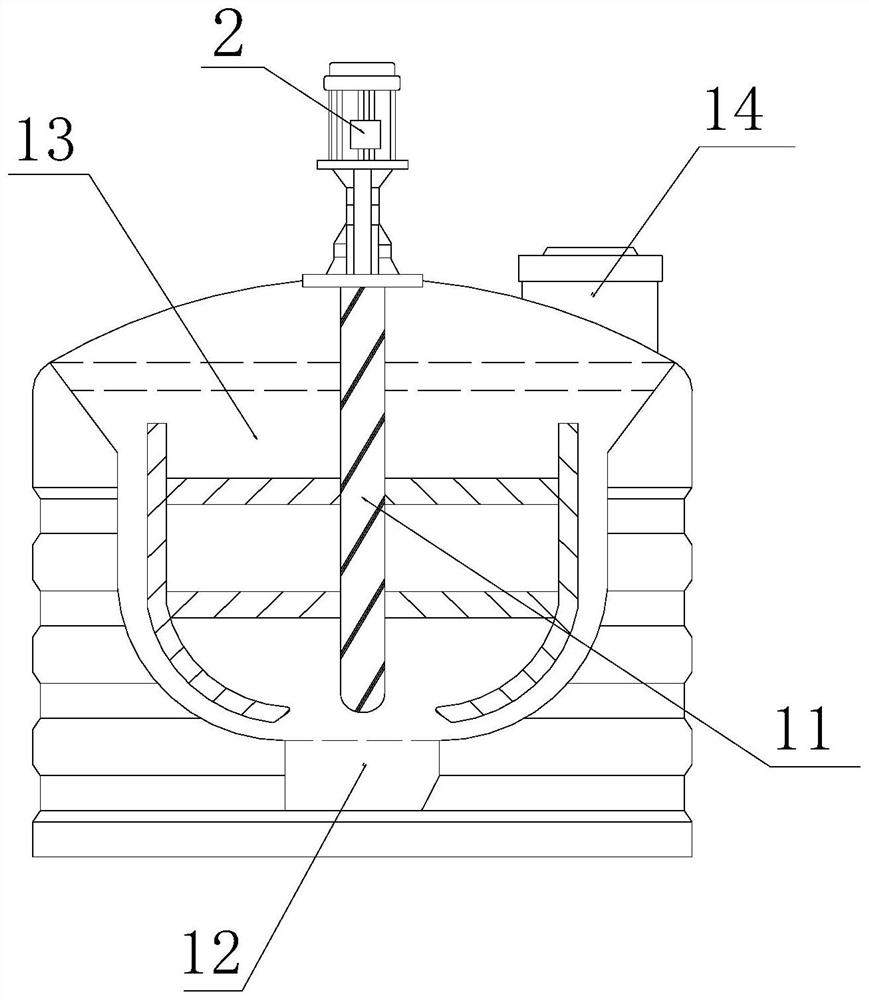

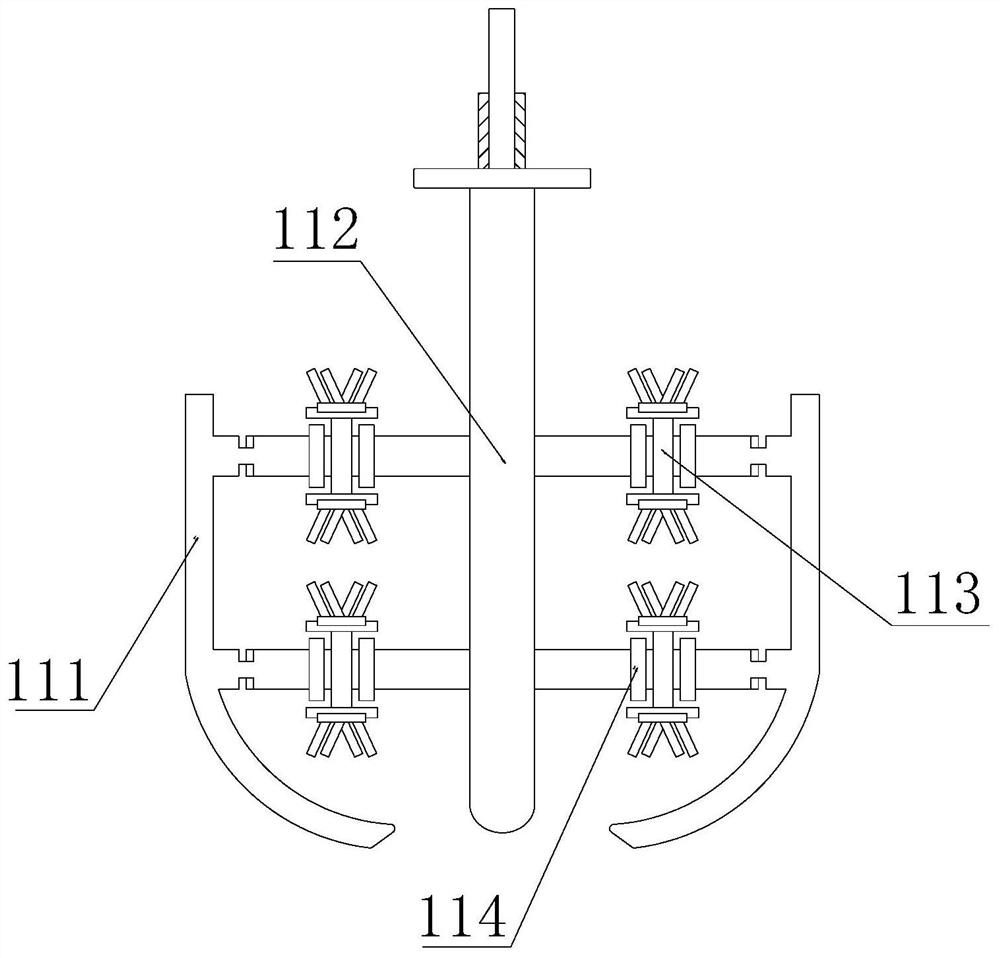

[0031] Its structure includes a fermenter 1, a drive motor 2, a support platform 3, and a guardrail 4. The top of the fermenter 1 is fixed to the integral bolt of the drive motor 2, and the surroundings of the fermenter 1 are in clearance with the inner side of the guardrail 4. The bottom of the column 4 is welded to the upper surface of the support platform 3, and the upper surface of the support platform 3 is embedded and connected to the bottom of the fermenter 1. The fermenter 1 includes an agitator 11, a diversion tank 12, a movable chamber 13, and a feeding port 14. The agitator 11 as a whole is movably coordinated with the inside of the movable chamber 13, the bottom of the movable chamber 13 is nested and connected with the upper surface of the diversion groove 12, and the lower end of the feeding port 14 is embedded and connected with the upper wall surface of the movable chamber 13 , the lower end of the feed...

Embodiment 2

[0038] as attached Image 6 to attach Figure 9 Shown:

[0039] Wherein, the movable chamber 13 includes an arc-shaped concave plate 131, an outer wall 132 of the cavity, a closed valve 133, and a discharge pipe 134. It is flange-connected with the end of the discharge pipe 134, and the top surface of the discharge pipe 134 is spirally connected with the inside of the airtight valve 133. The inner side of the airtight valve 133 is in clearance with the inner side of the arc-shaped concave disk 131, and the arc-shaped concave disk 131 is arc-shaped as a whole. Shaped concave shape, the bottom of the bottom end is flanged to the discharge pipe 134, wherein the arc-shaped concave plate 131 is conducive to the outward discharge speed of the industrial enzyme after fermentation inside the clamp block through its own arc angle.

[0040] Wherein, the arc-shaped concave disc 131 includes a downstream guide plate b1, a disc surface body b2, a retracting groove b3, and a drainage bar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com