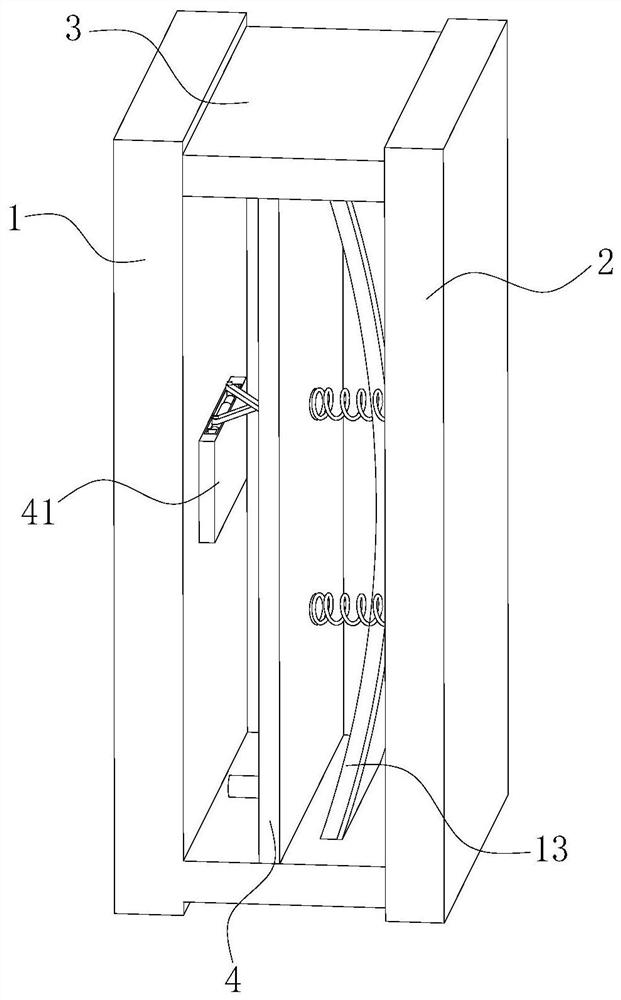

Double-layer ventilation curtain wall system

A curtain wall and double-layer technology, which is applied in the field of double-layer ventilated curtain wall systems, can solve the problems of high technical requirements and production costs, falling off, large noise and energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

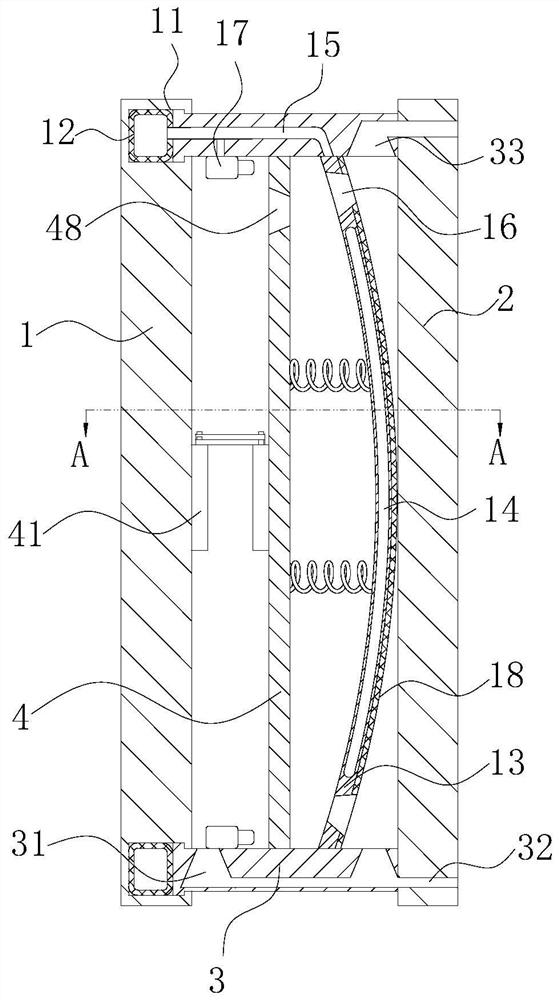

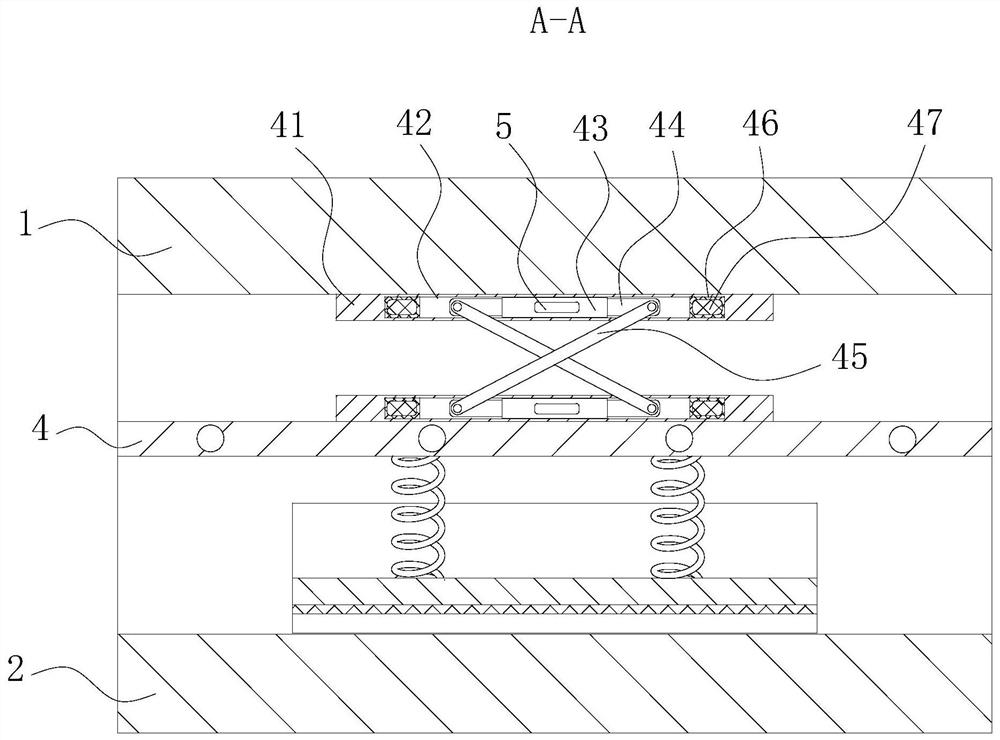

[0026] As an embodiment of the present invention, one side of the connecting plate 3 is fixedly connected with the outer curtain wall panel 2, and the other side is designed in a "T" shape, and the inner curtain wall panel 1 is opened with a The chute 11 of "T" shape design, the chute 11 is set corresponding to the connecting plate 3, one end of the connecting plate 3 is slidably connected with the inside of the chute 11, and one end of the connecting plate 3 and the inner wall of the chute 11 are arranged There is an airbag 12; an arc-shaped support plate 13 is arranged between two adjacent connecting plates 3, and the curved surface of the arched side of the support plate 13 is designed relative to the inner curtain wall panel 1, and the support plate 13 is made of elastic metal material; the inside of the support plate 13 is provided with a cavity 14, and the inside of the airbag 12 communicates with the cavity 14 through the air channel 15 provided inside the connecting rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com