Efficient leveling equipment for concrete roof

A concrete and high-efficiency technology, applied in the direction of roofing, tools for roof engineering, construction, etc., can solve problems such as errors and affect the flatness of the roof, and achieve the effect of improving the flatness, improving work efficiency, and expanding the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

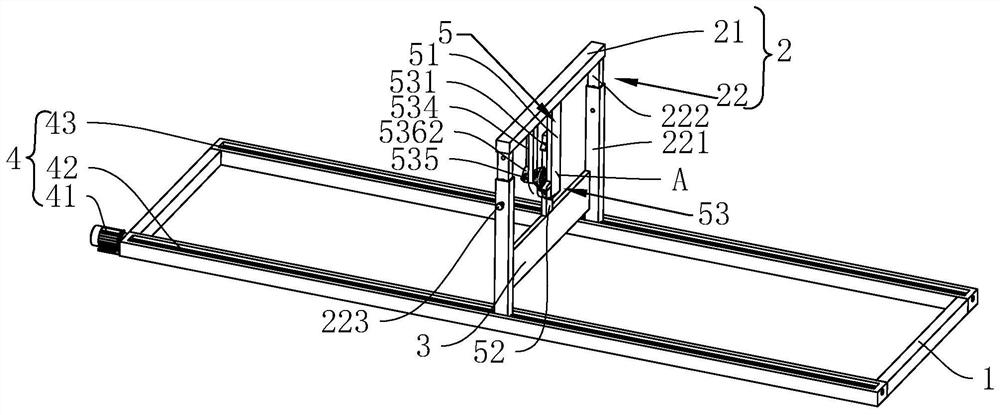

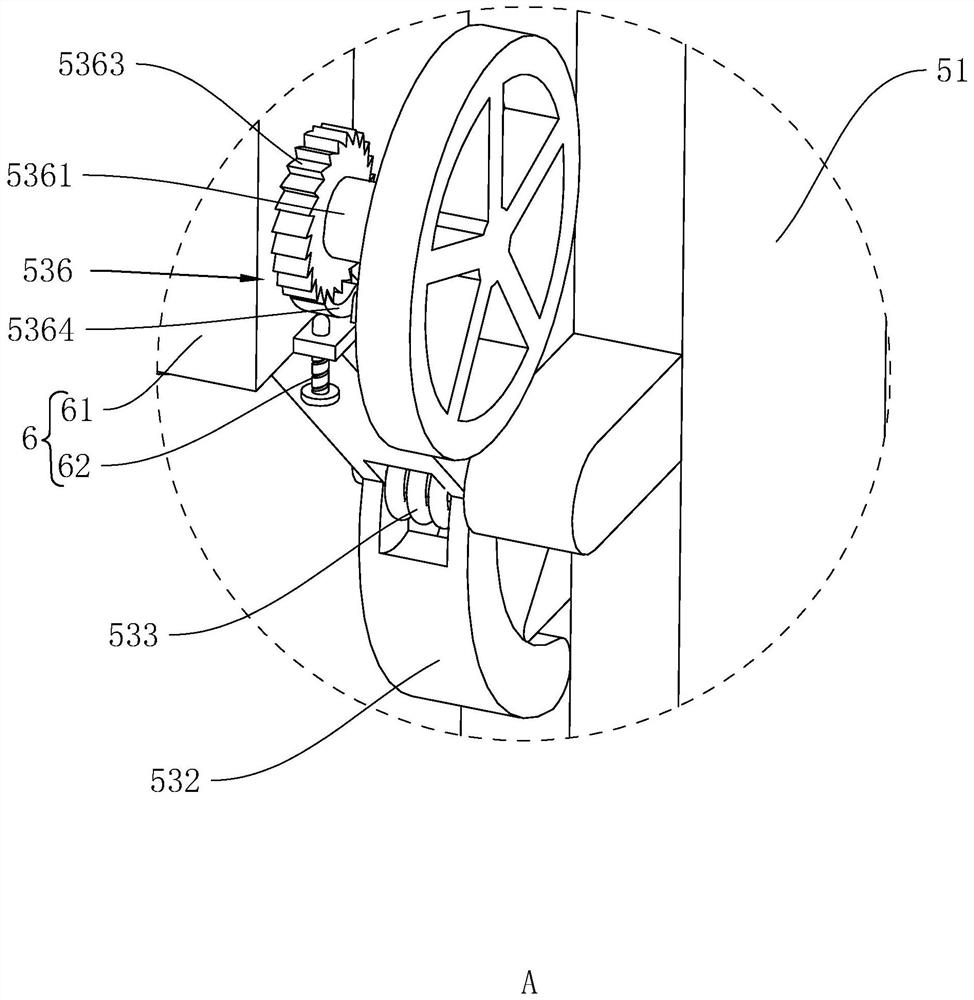

[0030] The following is attached Figure 1-2 The application is described in further detail.

[0031] The embodiment of the present application discloses a high-efficiency leveling equipment for concrete roofs.

[0032] refer to figure 1 , a high-efficiency leveling equipment for concrete roofs, including a slide rail 1, a bracket 2 located on the slide rail 1, a scraper 3 located on the bracket 2, a driving device 4 for driving the bracket 2 to move, and a lifting mechanism for the scraper 3 The lifting device 5, the slide rail 1 is fixed on the wall by bolts, the bracket 2 is slidingly connected with the slide rail 1, and the scraper 3 is detachably connected with the bracket 2; the bracket 2 includes a cross bar 21 and two support bars 22, and the scraper 3. It is detachably connected with the cross bar 21. The two ends of the cross bar 21 are respectively welded with two support rods 22. The end of the support rod 22 away from the cross bar 21 is slidably connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com