A Fluid-Solid-Heat Coupling Simulation Method for the Progressive Collapse Process of the Borehole Wall in Heterogeneous Formation

A simulation method, heterogeneous technology, applied in the field of rock mechanics and engineering, petroleum drilling engineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

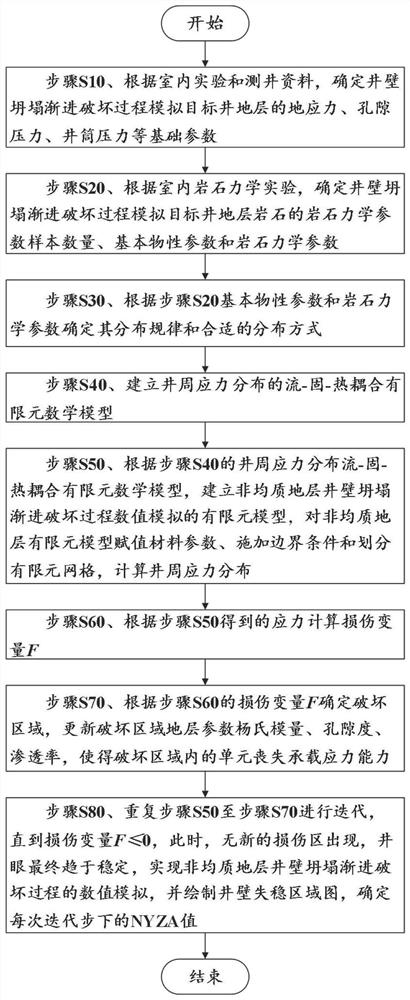

[0137] Step S10, according to laboratory experiments and logging data, determine the basic parameters such as in-situ stress, pore pressure, wellbore pressure and other basic parameters of the simulated target well formation during the gradual failure process of wellbore collapse;

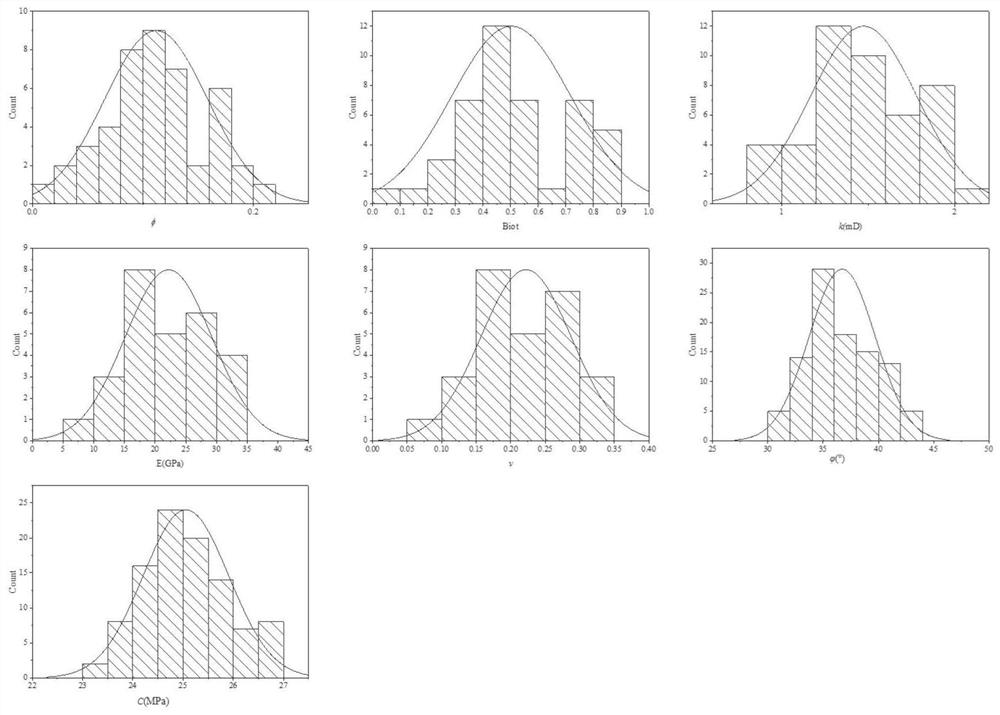

[0138] Step S20, according to the laboratory rock mechanics experiment, determine the rock mechanics parameter sample number 27, the basic physical property parameters and the rock mechanics parameter of the stratum rock of the target well during the gradual failure process of the borehole collapse simulation;

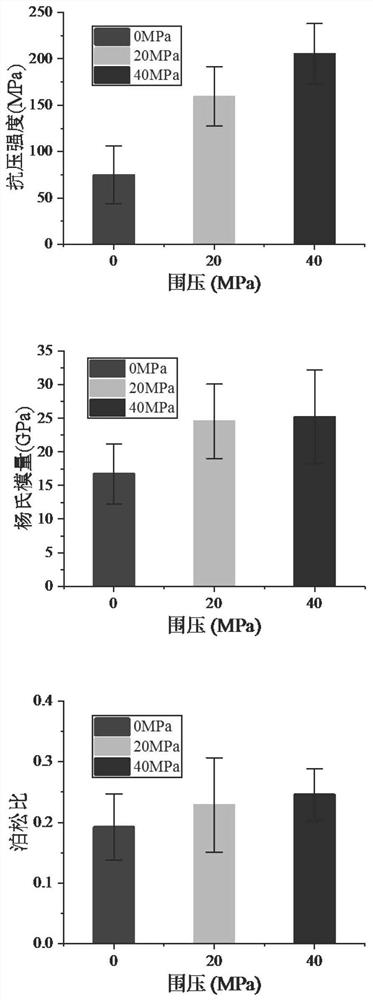

[0139] Described rock mechanics experiment comprises uniaxial compression and triaxial compression rock mechanics experiment, and experimental result is as follows figure 2 . It is not difficult to see that the elastic modulus and compressive strength both increase with the increase of the confining pressure, but the Poisson's ratio does not change significantly with the increase of the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com