Carrier for aerosol product and preparation method thereof

An aerosol and product technology, which can be used in applications, smoker products, e-liquid filters, etc., and can solve problems such as hazards and tar hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

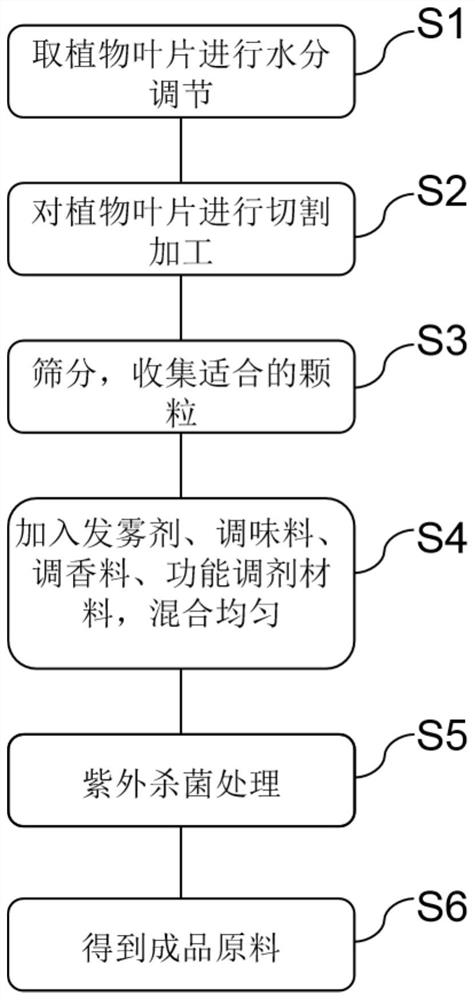

[0028] The preparation method of the carrier for aerosol products according to the second aspect of the present invention, such as figure 1 shown, including the following steps:

[0029] S1. Take plant leaves for moisture adjustment; S2. Cut and process plant leaves; S3. Sieve and collect suitable particles; S4. Add fogging agent, seasoning, flavoring spices and functional adjustment materials, and mix evenly; S5. Ultraviolet sterilizing treatment; S6, obtaining finished raw materials.

[0030] In some specific implementations of the present invention, the water content of plant leaves in step S1 is adjusted within a water content of 8.5±2%. By reasonably adjusting the moisture content of plant leaves, the problems of excessive moisture content, mildew, and low moisture content are avoided.

[0031] According to an embodiment of the present invention, the cutting process in step S2 is mechanical cutting.

[0032] Further, the number of sieving in step S3 is twice, and the s...

Embodiment 1

[0037] Take the required plant leaves, wash them and place them in the water conditioning equipment. After adjusting the moisture content of the leaves to 8.5±2%, the plant leaves are cut and processed, and passed through two layers of sieves of 0.5mm and 2mm respectively. Remove the materials greater than 2mm and less than 0.5mm, and the middle ones are usable materials. In parts by weight, weigh 50 parts of plant leaf particles, 30 parts of vegetable glycerin, 5 parts of seasonings, and 5 parts of flavoring spices and place them in a blender. Stir well at room temperature, and then put it under ultraviolet light for about 10 hours to sterilize, and then the finished material of the aerosol product can be prepared.

Embodiment 2

[0039] Take the required plant leaves, wash them and place them in the water conditioning equipment. After adjusting the moisture content of the leaves to 8.5±2%, the plant leaves are cut and processed, and passed through two layers of sieves of 0.5mm and 2mm respectively. Remove materials larger than 2mm and smaller than 0.5mm, and the middle ones are usable materials. Weigh 50 parts of plant leaf particles, 35 parts of vegetable glycerin, 5 parts of seasoning, 5 parts of spices, and 1 part of function adjustment in parts by weight. The material is placed in a mixer, fully stirred at room temperature, and then placed under an ultraviolet lamp for sterilization for about 10 hours, and the finished material of the aerosol product can be prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com