Automatic polishing machine for surface of long drill rod

An automatic polishing and drill rod technology, which is used in surface polishing machine tools, grinding/polishing equipment, grinding/polishing safety devices, etc. Quality and the effect of improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

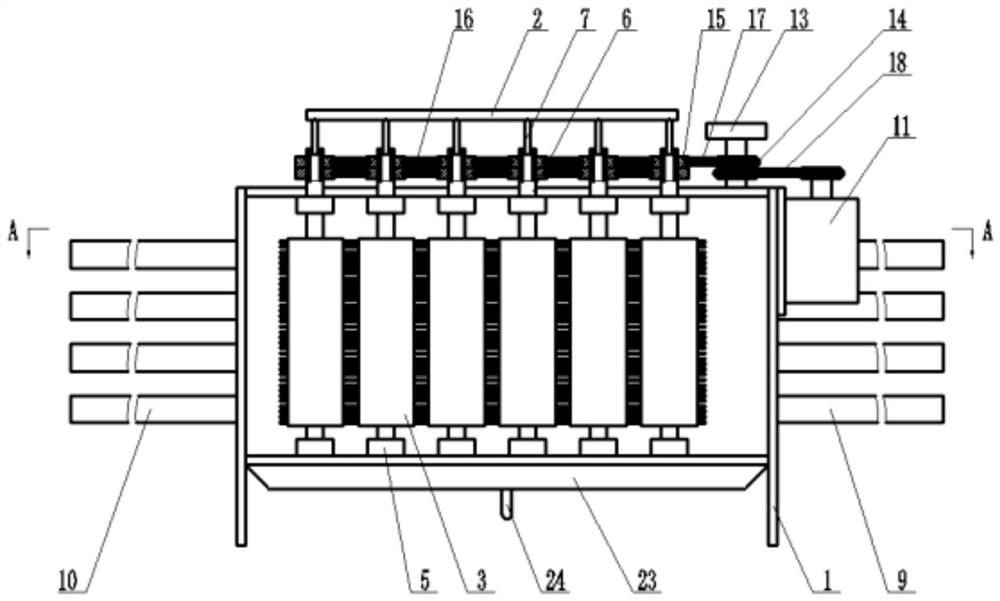

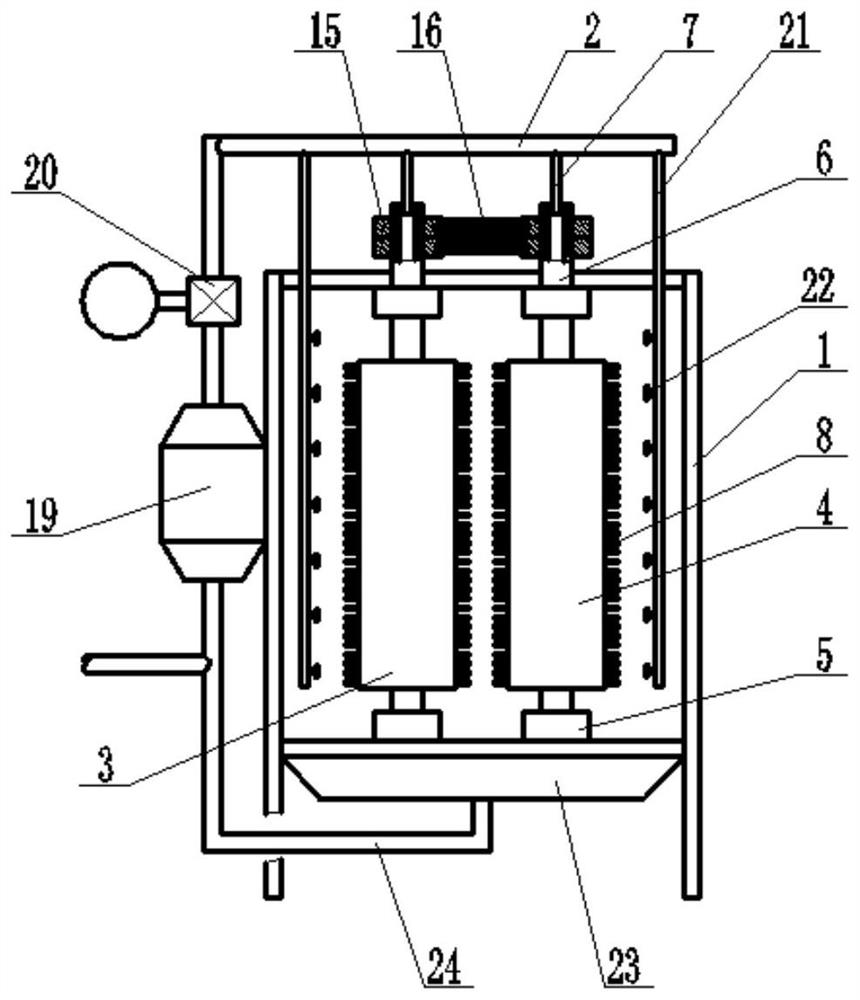

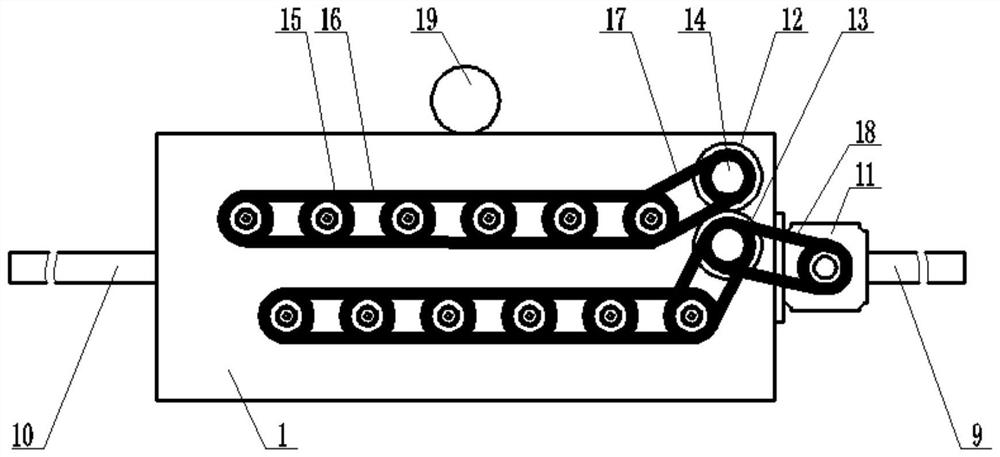

[0022] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, the present invention provides an automatic polishing machine for the surface of a long chisel, comprising a case shell 1, a liquid supply main pipe 2, a plurality of rollers A3 and a plurality of rollers B4, and the upper and lower ends of roller A and roller B4 respectively pass through The bearing seat 5 is installed in the box shell 1, the liquid inlet pipe 6 is fixedly connected to the roller A3 and the roller B4, and a plurality of distribution pipes 7 are connected to the liquid supply main pipe 2, and each distribution pipe 7 passes through the use of rolling bearings. Inserted in the liquid inlet pipe 6, the outer peripheral surfaces of the roller A3 and the roller B4 are provided with injection holes, and the outer peripheral surfaces of the roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com