A digital detection method and system for surface assembly quality of aircraft fuselage

A technology for aircraft fuselage and surface quality, applied in aircraft assembly, aircraft component testing, etc., can solve the problems of high labor intensity, poor precision, and low efficiency, and achieve the effect of ensuring assembly quality and reducing workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The present embodiment discloses a method for digitally detecting the surface assembly quality of an aircraft fuselage. As a basic embodiment of the present invention, it is characterized in that it includes pre-detection preparation and detection process implementation;

[0043] The pre-test preparations include the following steps:

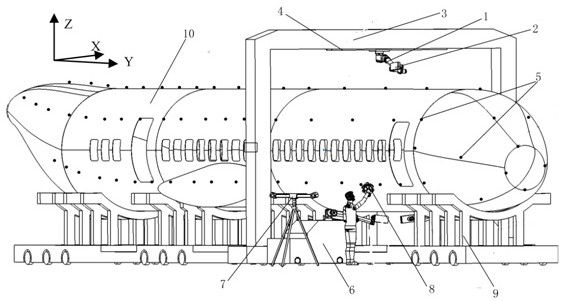

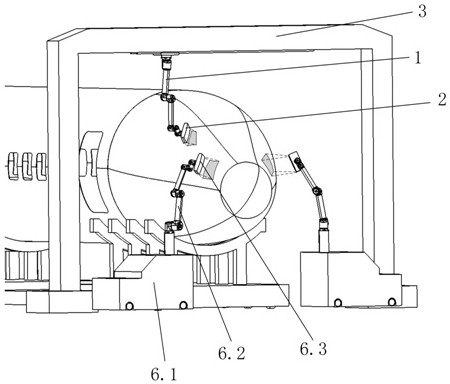

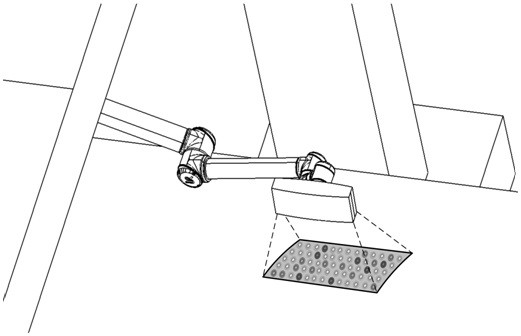

[0044] S11, laying out the digital inspection system: including installing the gantry inspection device on the ground, and placing two movable surface quality inspection devices 6 on the ground for inspecting the sides and abdomen of the aircraft fuselage 10; installing the gantry inspection device will have sufficient The high-height fixed gantry 3 is installed on a flat ground, and a linear guide 4 is set on the top of the inner side of the fixed gantry 3. One end of the measuring robot arm I1 is slidably connected to the fixed gantry 3 through the linear guide 4, and the other side of the measuring robot arm I1 is slidably connected. A...

Embodiment 2

[0059] This embodiment discloses a method for digitally detecting the surface assembly quality of an aircraft fuselage. As a preferred embodiment of the present invention, that is, in Example 1, it also includes using a tracking 3D scanning unit to perform manual supplementary measurement; tracking 3D scanning The unit includes an optical tracker 7 and a three-dimensional scanner 8. The positioning of the optical tracker 7 in the aircraft coordinate system is completed through the measurement mark points 5 on the aircraft fuselage 10, and then the three-dimensional scanner 8 is used to align the surface quality detector I2 and the two. Manual supplementary measurement is performed on the measurement area that cannot be covered by the movable surface quality detection device 6 . That is, facing the places that cannot be detected by the surface quality detector I2 and the movable surface quality detection device 6, such as the contact surface between the aircraft fuselage 10 and ...

Embodiment 3

[0064] This embodiment discloses a digital inspection system for the surface assembly quality of an aircraft fuselage. As a basic embodiment of the present invention, it includes an upper computer, a gantry inspection device, a side / abdominal inspection unit, and a transfer vehicle 9; the gantry inspection device includes a measurement The robotic arm I1, the surface quality detector I2 and the fixed gantry 3 installed on the ground, the measuring robotic arm I1 and the surface quality detector I2 are respectively connected to the upper computer for communication; One end of the arm I1 is slidably connected to the fixed gantry 3 through the linear guide 4, and the surface quality detector I2 is installed on the other end of the measuring robot arm I1; The movable surface quality detection device 6 on the abdomen of the aircraft, and the two movable surface quality detection devices 6 are respectively connected to the upper computer in communication;

[0065] In this technical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com