Device and method for converting cyanide-containing organic waste liquid into nitrogen-doped carbon nanomaterials

A technology of organic waste liquid and nitrogen-doped carbon, applied in chemical instruments and methods, nano-carbon, inorganic chemistry, etc., can solve complex engineering problems and other problems, achieve temperature control problems, solve gasification energy consumption problems, The effect of increasing the added value of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

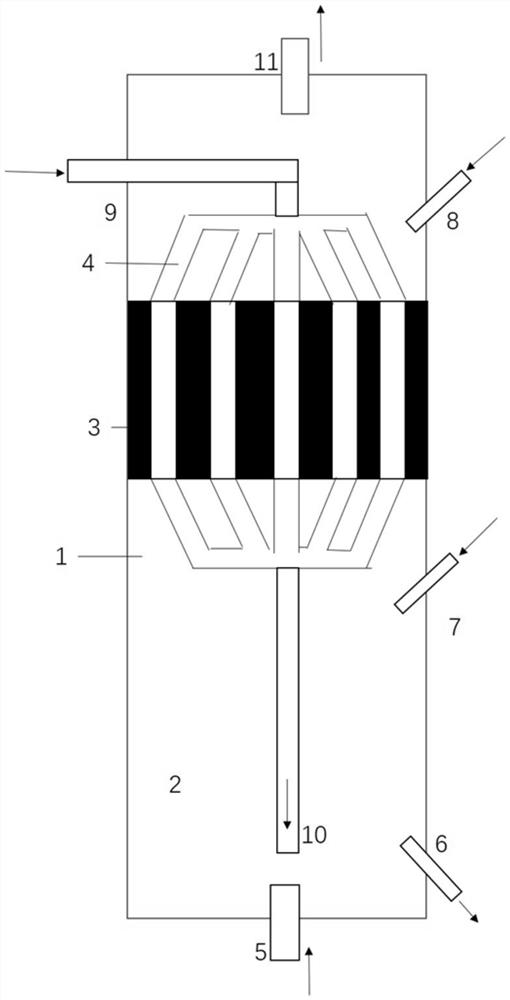

[0033] according to figure 1 In the assembled device, the height of the fixed bed section 3 is 1:5 of the height of the fluidized bed section 3 .

[0034]The fluidized bed section 2 is filled with catalyst (10% NiFe alloy (9% Fe-1% Ni)-42% alumina-48% magnesia) through the fluidized bed catalyst inlet 7, and the fixed bed catalyst is fed through the fixed bed catalyst inlet 8 to the fixed bed. Bed section 3 is packed with catalyst (1% Ni-1% W-98% silica). The weight of the catalyst in the fixed bed section 3 is 1:5 of the weight of the catalyst in the fluidized bed section 2. From the fluidized bed auxiliary gas inlet 5, the auxiliary fluidized bed gas (Ar) was introduced into the fluidized bed section 2, and its mass flow was 5% of the cyanide-containing organic waste liquid, and the fluidized bed section 2 was heated to 500 °C.

[0035] The cyanogen-containing organic waste liquid inlet 9 from the inlet of the vaporizer 4 is passed into the cyanogen-containing organic wast...

Embodiment 2

[0040] according to figure 1 In the assembled device, the height of the fixed bed section 3 is 1:4 of the height of the fluidized bed section 3 .

[0041] The fluidized bed section 2 is charged with catalyst (1% CoMoW alloy (0.9% Co-0.05% Mo-0.05% W)-99% silica) through the fluidized bed catalyst inlet 7, and the fixed bed is fed through the fixed bed catalyst inlet 8 Stage 3 was loaded with catalyst (10% Co-10% Mo-25% silica-55% alumina). The weight of the catalyst in the fixed bed section 3 is 2:1 of the weight of the catalyst in the fluidized bed section 2. From the fluidized bed auxiliary gas inlet 5, the auxiliary fluidized bed gas (Ar) was introduced into the fluidized bed section 2, and its mass flow was 1% of the cyanide-containing organic waste liquid, and the fluidized bed section 2 was heated to 800 °C.

[0042] From the cyanogen-containing organic waste liquid inlet 9 of the vaporizer 4, pass into the cyanide-containing organic waste liquid (organic substance wit...

Embodiment 3

[0047] according to figure 1 In the assembled device, the height of the fixed bed section 3 is 1:2 of the height of the fluidized bed section 3 .

[0048] The fluidized bed section 2 is charged with catalyst (30% NiCu alloy (10% Ni-20% Cu)-70% alumina) through the fluidized bed catalyst inlet 7, and the fixed bed section 3 is charged through the fixed bed catalyst inlet 8 Catalyst (10%Co-5%Mo-45%Magnesia-40%Alumina). The weight of the catalyst in the fixed bed section 3 is 2:1 of the weight of the catalyst in the fluidized bed section 3. From the fluidized bed auxiliary gas inlet 5 to the fluidized bed section 2), pass the auxiliary fluidized bed gas (Ar), the mass flow of which is 1% of the cyanide-containing organic waste liquid, and heat the fluidized bed section 2 to 750 ° C .

[0049] From the cyanogen-containing organic waste liquid inlet 9 of the vaporizer 4, the cyanogen-containing organic waste liquid (organic substance with a molecular weight of 26-350) is passed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com